A cordless fastening tool designed for precision woodworking tasks, this device utilizes a battery-powered mechanism to drive finish nails into various materials. Unlike pneumatic models that require an air compressor, this tool offers increased portability and convenience, eliminating the need for hoses and external power sources beyond battery charging. This autonomy makes it well-suited for job sites with limited power access or tasks requiring movement between different locations.

The value proposition of such a tool lies in its enhanced mobility and reduced setup time. The absence of a compressor significantly streamlines the workflow, enabling faster project completion and reducing the risk of tripping hazards associated with air hoses. Historically, finish nailers have been tethered to compressors, restricting their use. This cordless iteration represents a significant advancement, allowing for greater freedom and efficiency on the job. Its adoption can lead to increased productivity and potentially lower operational costs by removing the need for compressor maintenance and electricity usage.

The following sections will delve into the specific features, operational characteristics, and suitable applications of this type of cordless nailer. Performance metrics, nail size compatibility, and battery life considerations will be addressed, alongside safety features and maintenance recommendations. Further analysis will explore optimal usage scenarios and compare it with traditional pneumatic alternatives.

Operation and Maintenance Tips

Adherence to these guidelines will ensure optimal performance, extend the service life, and promote safe operation of cordless finish nailers.

Tip 1: Battery Management: Prioritize complete battery charging cycles. Avoid frequent partial charges, as this may reduce overall battery capacity. Store batteries in a cool, dry environment when not in use.

Tip 2: Nail Selection: Utilize the correct nail gauge and length specified by the manufacturer. Using improper fasteners can lead to tool jamming or damage to the workpiece.

Tip 3: Depth Adjustment: Precisely adjust the nail depth setting according to the material being fastened. This prevents overdriving the nails and damaging the surface.

Tip 4: Consistent Maintenance: Regularly inspect the nail magazine and firing mechanism for debris or obstructions. Clean these components with compressed air or a dry cloth to ensure smooth operation.

Tip 5: Workpiece Support: Adequately support the workpiece to prevent movement during fastening. This ensures accurate nail placement and reduces the risk of kickback.

Tip 6: Safety Precautions: Always wear appropriate eye and ear protection when operating the tool. Disconnect the battery pack when performing maintenance or changing nails.

Tip 7: Storage Considerations: Store the tool in a designated carrying case when not in use. This protects the tool from damage and prevents accidental activation.

By implementing these measures, users can maximize the efficiency and lifespan of the cordless finish nailer, resulting in consistent and reliable performance. Consult the operator’s manual for specific details and warranty information. The conclusion will summarize the benefits of this tool and offer a final perspective on its role in various woodworking applications.

1. Cordless Operation

Cordless operation represents a pivotal attribute of the finish nailer, directly influencing its usability and range of applications. The absence of pneumatic lines affords enhanced mobility and eliminates the constraints associated with traditional compressor-dependent systems. This design feature has significant implications for efficiency and versatility in various work environments.

- Enhanced Portability

Cordless operation facilitates movement around job sites without the encumbrance of hoses or the need for proximity to a compressor. This is particularly advantageous in environments where accessibility is limited or where tasks require frequent relocation. For example, finish carpenters working on large-scale residential projects can transition seamlessly between rooms and floors without the logistical challenges of repositioning an air compressor and its associated lines.

- Reduced Setup Time

The elimination of compressor setup translates to a more streamlined workflow. Users can immediately commence fastening tasks without waiting for the compressor to build pressure or dealing with hose management. This rapid deployment capability is particularly beneficial for smaller projects or punch-list items where quick and efficient completion is paramount. The time saved can be reinvested in other critical aspects of the project, enhancing overall productivity.

- Noise Reduction

Air compressors are known for generating substantial noise during operation. Cordless finish nailers, by virtue of their design, significantly reduce noise pollution, creating a more comfortable and less disruptive work environment. This is especially important in residential settings or locations where noise restrictions are in effect. The reduced noise level also improves communication among workers and minimizes potential hearing hazards.

- Power Source Flexibility

Cordless models typically rely on rechargeable battery packs, offering flexibility in power source options. This allows users to operate the nailer in areas where electrical outlets may not be readily available. Furthermore, the availability of multiple battery packs ensures continuous operation, minimizing downtime. The user must ensure that the battery is appropriate for the tool’s voltage requirements.

The aforementioned factors underscore the considerable advantages of cordless operation in the context of finish nailers. This design promotes greater efficiency, enhanced portability, and a more user-friendly experience. The cordless design contributes to an improvement in overall productivity for those utilizing the fastening tools.

2. Brushless Motor

The integration of a brushless motor within a cordless finish nailer represents a significant advancement in tool technology, directly impacting performance, durability, and overall efficiency. Its utilization moves away from traditional brushed motors, presenting advantages specific to demanding applications.

- Enhanced Efficiency

Brushless motors operate with minimal friction due to the absence of brushes making physical contact. This translates to higher energy conversion efficiency, meaning a greater percentage of the battery’s power is utilized to drive the nail, as opposed to being lost as heat. In practical terms, this results in longer runtimes per battery charge, allowing for extended periods of use without interruption. For the cordless finish nailer, this increased efficiency is crucial for maintaining consistent performance throughout extended projects.

- Increased Lifespan

The primary wear component in a brushed motor is the brush itself, which degrades over time due to constant friction. Brushless motors eliminate this component, significantly extending the motor’s lifespan. This translates to reduced maintenance requirements and a lower total cost of ownership over the tool’s lifespan. The cordless finish nailer, often subjected to heavy use, benefits significantly from the enhanced durability of a brushless motor.

- Reduced Heat Generation

The friction inherent in brushed motors generates substantial heat, which can impact performance and potentially damage the motor. Brushless motors, with their reduced friction, produce considerably less heat. This not only improves the motor’s efficiency but also contributes to a more comfortable user experience, especially during prolonged operation. The cordless finish nailer benefits from reduced heat buildup, maintaining consistent power and preventing overheating during demanding tasks.

- Optimized Power Delivery

Brushless motors allow for more precise electronic control of torque and speed. This enables the tool to deliver consistent power regardless of the load, ensuring reliable nail driving even in dense materials. The enhanced control also allows for features like adjustable power settings to optimize performance for different nail sizes and material types. With this precise control, the cordless finish nailer offers improved accuracy and reduced instances of nail misfires or jams.

In conclusion, the adoption of brushless motor technology in a cordless finish nailer is not merely a design choice but a critical factor contributing to the tool’s enhanced performance, longevity, and user experience. Each characteristic discussed, from superior efficiency to extended lifespan, directly enhances the value and applicability of the tool for various woodworking and construction tasks.

3. Depth Adjustment

Depth adjustment is a critical feature integrated into the design of cordless finish nailers. This capability provides users with the means to precisely control the depth at which fasteners are driven into various materials, mitigating surface damage and ensuring secure fastening.

- Material Compatibility

Different materials exhibit varying densities and resistance to penetration. Softwoods require less driving force compared to hardwoods. An adjustable depth setting allows users to calibrate the tool to match the specific material properties, preventing nails from being overdriven in softer materials or underdriven in denser ones. This prevents cosmetic damage and ensures secure fastening across a range of material types encountered on job sites.

- Flush Fastening

The primary goal of finish nailing is to achieve a flush or slightly countersunk nail head without damaging the surrounding material. Accurate depth adjustment enables this precise control. A setting that is too shallow will result in protruding nail heads, while one that is too deep can mar the surface. The ability to fine-tune the depth allows for clean, professional-looking results, which is crucial for finish carpentry applications.

- Fastener Type Variation

Finish nailers are often used with different lengths and gauges of nails. While the tool is designed to accommodate a range of fastener sizes, depth adjustment may be necessary to optimize performance for each specific nail type. Longer nails, for example, might require a shallower setting to prevent them from piercing through the back of thinner materials. The adjustability ensures the tool remains versatile across various fastening tasks.

- User Control and Precision

The depth adjustment mechanism provides users with direct control over the tool’s performance. Typically, this involves a dial or knob that allows for incremental adjustments to the driving depth. This control is essential for achieving consistent results and adapting to unforeseen variations in material density or tool performance. Experienced users can leverage this feature to optimize the tool for specific tasks and achieve professional-quality results.

The integration of a robust depth adjustment mechanism directly enhances the versatility and precision of cordless finish nailers. By allowing users to adapt to different materials, fastener types, and application requirements, this feature ensures optimal fastening performance and minimizes the risk of surface damage. Proper utilization of depth adjustment is essential for achieving professional-quality results in various woodworking and finishing applications.

4. Nail Compatibility

Nail compatibility represents a fundamental parameter governing the functionality and utility of cordless finish nailers. Adherence to specified nail dimensions and types ensures consistent performance, prevents tool malfunction, and guarantees secure fastening. The following facets detail the critical aspects of nail compatibility relevant to the effective operation of this fastening system.

- Gauge Specification

The gauge, denoting nail thickness, is a primary determinant of compatibility. Cordless finish nailers are engineered to accept a specific gauge range, typically 15 or 16 gauge. Utilizing nails outside this range can lead to jamming, misfires, and potential damage to the tool’s internal mechanisms. Selection of the correct gauge ensures proper alignment within the nail magazine and consistent feeding into the driving chamber.

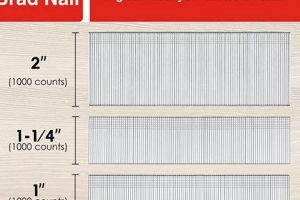

- Length Range Adherence

Each finish nailer model is designed to accommodate a defined range of nail lengths, typically spanning from 1 inch to 2.5 inches. Employing nails exceeding the maximum length can obstruct the firing mechanism, preventing proper operation. Using nails shorter than the minimum specified length may result in inadequate holding power and compromised fastening integrity. Adherence to the prescribed length range is crucial for achieving consistent and reliable results.

- Collation Type Consistency

Nails used in finish nailers are collated, meaning they are joined together in strips or coils for efficient loading into the magazine. The collation type, whether glued, plastic, or wire, must be compatible with the nailer’s feeding system. Incompatible collation can cause feeding issues, resulting in jams and interruptions during operation. Verification of collation compatibility prior to use is essential for maintaining smooth and uninterrupted workflow.

- Head Style Consideration

The head style of the nail, whether brad, angled, or T-head, influences the tool’s performance and the aesthetic outcome of the fastening. Selecting the appropriate head style ensures proper seating and minimizes visible impressions on the workpiece surface. Consideration of head style compatibility contributes to achieving a professional and aesthetically pleasing finish, particularly in applications where the fastener is partially exposed.

In summary, nail compatibility encompasses a multifaceted set of considerations that directly impact the performance and longevity of cordless finish nailers. Proper attention to gauge, length, collation type, and head style ensures optimal functionality, minimizes the risk of malfunction, and contributes to achieving high-quality fastening results. The failure to adhere to these parameters can compromise the tool’s performance and reduce the quality of the finished product.

5. Portability advantage

The inherent portability of a cordless, airless finish nailer significantly expands its application range and enhances user convenience compared to pneumatic counterparts. This advantage stems from the elimination of air compressors and connecting hoses, fundamentally altering the tool’s operational dynamics.

- Elimination of Compressor Dependence

The absence of an air compressor removes a significant constraint on mobility. Traditional pneumatic nailers require a bulky and often stationary compressor, limiting the user’s range of operation. The cordless design allows users to operate the nailer in locations lacking access to compressed air, such as remote job sites or areas with limited electrical power. This independence translates to increased efficiency and reduced setup time. A carpenter working on a remote cabin, for example, can utilize the tool without the need for transporting a heavy compressor or relying on a generator.

- Reduced Setup and Breakdown Time

The removal of pneumatic hoses streamlines the setup and breakdown processes. Connecting and disconnecting hoses, as well as managing their length and placement, can be time-consuming and cumbersome. With a cordless model, the user simply inserts a battery and is ready to work. This efficiency is particularly beneficial for tasks requiring frequent relocation or short bursts of activity. For a contractor performing punch-list work in a multi-story building, the time saved by eliminating hose management can be substantial.

- Enhanced Maneuverability in Confined Spaces

The compact form factor and lack of hoses improve maneuverability in tight or cluttered workspaces. Traditional pneumatic hoses can be unwieldy and can create tripping hazards. The cordless design allows the user to navigate confined spaces with greater ease, improving safety and productivity. For instance, installing trim in a small bathroom or attic is greatly simplified by the tool’s enhanced maneuverability.

- Simplified Transportation and Storage

The reduced weight and lack of associated equipment simplify transportation and storage. A cordless nailer can be easily transported in a toolbox or carrying case, minimizing the physical strain on the user. Storage requirements are also reduced, as there is no need to accommodate bulky compressors or lengthy hoses. This is especially relevant for tradespeople who frequently move between job sites or have limited storage space available. This contributes to greater organization of workspace.

These factors collectively highlight the significant portability advantages afforded by a cordless, airless finish nailer. By eliminating the constraints associated with pneumatic systems, this tool empowers users with greater flexibility, efficiency, and convenience across a wide range of applications. These benefits make it a compelling alternative for professionals and DIY enthusiasts seeking enhanced productivity and versatility.

Frequently Asked Questions

The following section addresses common inquiries regarding cordless finish nailers, focusing on performance characteristics, operational considerations, and maintenance requirements.

Question 1: What is the typical battery runtime for a cordless finish nailer under continuous use?

Battery runtime is contingent upon several factors, including battery voltage, amp-hour rating, nail size, and material density. Under continuous use driving 2-inch nails into pine, a fully charged 20V, 4.0Ah battery can typically deliver between 600 to 800 shots. Heavier materials or larger nails will reduce this number. The user must refer to the manufacturer’s specifications for precise estimates.

Question 2: Does a cordless finish nailer provide comparable power to a pneumatic model?

Modern cordless finish nailers equipped with brushless motors offer comparable power to many pneumatic models. While older cordless versions may have exhibited performance limitations, current technology provides sufficient driving force for most finish carpentry applications. The user should evaluate the tool’s specifications, including impact force and nail driving speed, to ensure suitability for the intended tasks.

Question 3: What maintenance procedures are required for a cordless finish nailer?

Routine maintenance primarily involves keeping the nail magazine and firing mechanism free of debris. Compressed air can be used to remove sawdust and nail fragments. Periodic lubrication of the driver track, as recommended by the manufacturer, is also crucial. The battery terminals should be cleaned regularly to ensure proper contact. Do not submerge any part of the tool in liquid.

Question 4: Can a cordless finish nailer be used for heavy-duty applications such as framing?

Cordless finish nailers are designed for finish carpentry tasks, not heavy-duty framing. Attempting to use a finish nailer for framing applications may result in tool damage and compromised structural integrity. Framing requires specific nailer types and fastener dimensions not supported by finish nailers.

Question 5: What safety precautions should be observed when operating a cordless finish nailer?

Users must always wear appropriate eye protection to guard against flying debris. Ear protection is also recommended, particularly during prolonged use. The tool should be disconnected from the battery pack before performing any maintenance or clearing jams. The operator’s manual should be consulted for comprehensive safety guidelines.

Question 6: How does the cost of a cordless finish nailer compare to a pneumatic system?

The initial cost of a cordless finish nailer is typically higher than that of a comparable pneumatic nailer. However, the overall cost of ownership may be comparable or lower over time, considering the elimination of compressor maintenance and electricity costs associated with pneumatic systems. Long-term costs depend on usage patterns and the lifespan of both the tool and its batteries.

The above answers address frequently encountered questions concerning the application and maintenance of cordless finish nailers. Users should always consult the tool’s operating manual for detailed specifications and safety procedures.

The following section will provide an overview of the specifications.

Conclusion

This exploration has illuminated the multifaceted characteristics of the dewalt airless finish nailer. It has been established that its cordless design, powered by a brushless motor, offers considerable advantages in portability and efficiency. Depth adjustment provides enhanced control, while nail compatibility ensures versatility across applications. The tool’s capabilities and limitations, including battery life and appropriate usage scenarios, have been defined.

Ultimately, the dewalt airless finish nailer represents a significant advancement in fastening technology. Its adoption warrants careful consideration by professionals and DIY enthusiasts seeking a balance of performance, convenience, and long-term cost effectiveness. Informed decision-making, guided by a thorough understanding of its specifications and operational requirements, will ensure optimal utilization of this tool in various woodworking endeavors. Continued research and adherence to manufacturer guidelines are crucial for maximizing its potential and upholding safety standards.