A surface application on wood, often a type of hardwood, imparts a desired color and protective layer. This process enhances the wood’s natural grain patterns while providing resistance to wear, moisture, and staining. For example, a light-colored, durable coating applied to furniture grade lumber yields an aesthetically pleasing and long-lasting product.

The implementation of such coatings is significant due to its capacity to preserve the integrity of the underlying material, extending its service life. Historically, these applications have been valued for both their practical benefits and their ability to elevate the visual appeal of wooden objects, reflecting societal tastes and technological advancements in material science.

The following sections will delve into specific types, application techniques, and maintenance considerations associated with this widely adopted practice in woodworking and related industries.

Tips for Achieving a Superior Coating

These guidelines are designed to optimize the quality and longevity of wood surfaces treated with a protective layer. Adhering to these recommendations will contribute to a durable and aesthetically pleasing result.

Tip 1: Surface Preparation is Paramount. Proper sanding, cleaning, and removal of any existing coatings are crucial. A smooth, contaminant-free substrate allows for optimal adhesion and uniformity. Failure to adequately prepare the surface can lead to blistering, peeling, or uneven color distribution.

Tip 2: Select the Appropriate Product. Different types offer varying levels of durability, color options, and application properties. Consider the intended use of the wood item and the desired aesthetic outcome when choosing a specific product. Water-based options offer low VOCs, while oil-based options may provide superior durability.

Tip 3: Apply Thin, Even Coats. Multiple thin coats are preferable to a single thick coat. Thin coats dry more evenly, reducing the risk of runs, drips, and trapped solvents. Use a high-quality brush, sprayer, or applicator pad to achieve a consistent finish.

Tip 4: Allow Adequate Drying Time. Refer to the manufacturer’s instructions for recommended drying times between coats. Insufficient drying can compromise the integrity of the coating and lead to premature failure. Ensure proper ventilation during the drying process.

Tip 5: Consider a Sealer or Primer. A sealer or primer can improve adhesion, reduce the amount of required, and prevent discoloration of the underlying wood. These products create a barrier that enhances the overall performance of the finishing system.

Tip 6: Use Proper Application Techniques. Apply with the grain of the wood. When spraying, maintain a consistent distance and overlap each pass by approximately 50%. Brush strokes should be long, even, and blended smoothly.

Tip 7: Test the Finish in an Inconspicuous Area. Before applying to the entire project, test the on a small, hidden section to ensure the desired color, sheen, and adhesion are achieved. This step prevents unwanted surprises and costly rework.

Adherence to these principles promotes a professional-grade outcome, ensuring the protection and aesthetic enhancement of treated wood surfaces. The resulting durability and visual appeal contribute significantly to the long-term value of the finished product.

The following sections will address the maintenance and long-term care considerations crucial to preserving the integrity and appearance of treated surfaces.

1. Durability

The durability of a coating directly influences its capacity to withstand wear, abrasion, and environmental stressors over time. When applied to ash wood, a durable enhances the wood’s inherent strength, providing a protective barrier against scratches, impacts, and moisture penetration. The choice of material significantly affects the lifespan of the treated item; for instance, a polyurethane-based formulation generally offers greater resistance to abrasion compared to a wax-based treatment, making it more suitable for high-traffic surfaces like flooring or countertops. A lack of durability leads to premature wear, requiring frequent reapplication and increasing maintenance costs.

Consider a gymnasium floor made of ash wood. Applying a durable, multi-layered polyurethane enhances not only the visual appeal but also provides the required impact resistance to withstand the constant activity. In contrast, a lightly oiled surface, while aesthetically pleasing initially, would quickly degrade under similar conditions. Similarly, exterior applications, such as garden furniture constructed from ash wood, necessitate a robust treatment to protect against UV exposure and moisture, preventing cracking, warping, and decay. The selection of a UV-resistant formula is therefore vital in these scenarios.

Ultimately, durability is a cornerstone of a successful application. Understanding its influence on the lifespan and performance of the coated ash wood is paramount. The practical significance of choosing an appropriate, durable solution extends beyond aesthetics, representing a long-term investment in the protection and preservation of the underlying material. Any compromise on durability often results in increased maintenance demands, reduced service life, and potentially, complete replacement of the treated item.

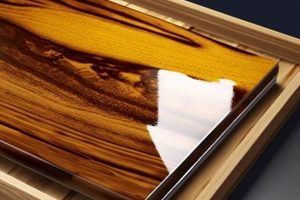

2. Appearance

The aesthetic aspect of an applied treatment to ash wood constitutes a significant determinant of its perceived value and suitability for a given application. The characteristics color, sheen, and grain enhancement directly impact the visual appeal of the wood. The choice of treatment significantly influences these elements. For instance, a clear, matte polyurethane maintains the wood’s natural color and minimizes glare, suitable for designs emphasizing understated elegance. Conversely, a tinted, high-gloss lacquer dramatically alters the color and reflectivity, appropriate for contemporary aesthetics. The resultant appearance is a direct function of the selected materials and the application technique employed.

The consideration of appearance is critical across various applications. In furniture manufacturing, the selected treatment dictates whether the wood will present a rustic, textured surface or a smooth, polished one. The choice aligns with the overall design objective and target market. For architectural millwork, where ash wood might be employed for molding or paneling, the applied treatment determines the visual consistency and integration with the surrounding environment. The application affects its integration with other design elements, therefore the selected finish can either complement or detract from its surroundings.

In conclusion, the resultant appearance is inextricably linked to the selection and application of a particular treatment for ash wood. The resulting visual outcome impacts its appropriateness for specified applications. Understanding this relationship allows for informed decision-making. Considerations of color, sheen, and grain enhancement are essential for achieving the desired aesthetic and maximizing the overall value of the treated wood. Any misalignment between the intended application and the chosen material compromises the intended design and aesthetic.

3. Protection

The protective characteristics imparted by a wood surface treatment are fundamentally linked to the longevity and preservation of the substrate. In the context of ash wood, the selection of an appropriate formulation is critical to mitigate degradation from environmental factors. Mechanical damage, moisture ingress, and ultraviolet radiation represent primary threats that can be significantly reduced through the application of a well-chosen protective layer. The causal relationship between the type of treatment and the degree of protection is direct; a high-performance urethane, for instance, offers superior abrasion resistance compared to a simple oil application, safeguarding against scratches and wear in high-traffic areas. Its importance as a component of a complete system cannot be overstated.

Consider exterior applications where ash wood is used for decking or siding. Without adequate protection, prolonged exposure to moisture leads to swelling, rot, and eventual structural failure. Similarly, ultraviolet radiation degrades the lignin in the wood, causing discoloration and surface checking. A protective treatment containing UV inhibitors and water repellents effectively combats these processes, extending the lifespan of the wood and reducing the need for frequent repairs or replacements. Interior applications also benefit; countertops treated with a food-safe, water-resistant finish resist staining and bacterial growth, enhancing hygiene and durability. The correct choice of product, therefore, represents a proactive measure against potential damage, contributing to long-term cost savings and sustained aesthetic appeal.

In summary, the level of protection afforded by a treatment directly influences the performance and lifespan of ash wood. Understanding the specific threats to which the wood will be exposed allows for the selection of a formulation that provides optimal defense. Challenges remain in balancing the desired aesthetic with the required protective properties, necessitating careful consideration of the available options. Prioritizing protection is a key element in ensuring the long-term value and functionality of any object or structure incorporating ash wood, directly addressing the core concerns of durability and sustainability.

4. Application

The process of applying a to ash wood significantly determines the final quality and longevity of the protected surface. Careful attention to technique, environmental conditions, and equipment is paramount for achieving optimal results.

- Surface Preparation

Prior to any coating, the ash wood surface must be properly prepared. This involves sanding to achieve the desired smoothness, cleaning to remove dust and contaminants, and potentially applying a wood conditioner to ensure uniform stain absorption. Inadequate preparation leads to adhesion failures, uneven coloring, and a compromised surface. For example, leaving sanding dust on the surface prevents the from bonding correctly, resulting in peeling.

- Application Method

Various application methods exist, each influencing the final appearance and durability. Brushing, spraying, and wiping are common techniques. Brushing is suitable for smaller projects and allows for precise control, while spraying provides a more uniform coverage on larger surfaces. Wiping is often used for applying oils and stains, enhancing the wood grain. The choice depends on the viscosity of the , the size of the project, and the desired aesthetic. For instance, spraying a lacquer on a large ash wood table yields a smooth, even surface, whereas brushing might leave noticeable brush marks.

- Environmental Conditions

Environmental factors during application significantly impact the outcome. Temperature and humidity levels influence drying times and can affect the flow and leveling of the . High humidity can slow down drying, leading to runs and sags, while extreme temperatures can cause the to dry too quickly, resulting in brush marks or orange peel texture. Maintaining optimal conditions as specified by the manufacturer ensures proper curing and a durable finish. A professional woodworker monitors humidity and temperature in their shop to achieve a consistent across all projects.

- Equipment and Material Quality

The quality of the application equipment and the chosen has a direct bearing on the final product. Using high-quality brushes, spray guns, and applicators ensures even distribution and minimizes imperfections. Selecting a that is compatible with ash wood and designed for the intended use is crucial. Cheaper products may contain inconsistent pigments or lack the necessary protective properties. A professional refinisher invests in high-quality spray equipment and durable materials to produce a superior and longer lasting .

These facets of application are interwoven, with each element contributing to the success or failure of the process. Understanding and controlling these factors guarantees the desired aesthetic and protective qualities of the , thereby enhancing the value and lifespan of the ash wood.

5. Maintenance

Proper maintenance is intrinsically linked to the longevity and aesthetic appeal of ash wood surfaces treated with a protective layer. Consistent and appropriate maintenance practices are essential for preserving the integrity and appearance of the , preventing premature degradation and ensuring long-term value.

- Regular Cleaning Protocols

Routine cleaning is paramount for removing surface contaminants that can abrade or degrade the . The frequency and method of cleaning should be tailored to the specific type of and the level of use the surface experiences. For instance, a lightly oiled surface requires gentle dusting and occasional polishing with specialized oils, while a polyurethane-coated floor can withstand damp mopping with a mild detergent. Neglecting regular cleaning allows dirt and grime to accumulate, potentially scratching the or dulling its sheen. Examples include using a soft cloth to wipe down furniture or using a vacuum cleaner with a brush attachment for floors. Regular removal of spills and stains is also important to prevent permanent damage.

- Surface Protection Measures

Implementing protective measures minimizes the risk of physical damage to the . Using coasters under beverages, placemats under dishes, and felt pads under furniture legs prevents scratches, dents, and water rings. In high-traffic areas, area rugs offer an additional layer of protection against abrasion. For exterior applications, awnings or covers can shield the from excessive sunlight and moisture. Failure to implement these measures accelerates wear and tear, necessitating more frequent refinishing or repairs. Placing a doormat at entrances helps reduce the amount of dirt and debris tracked onto ash wood floors, minimizing the need for aggressive cleaning.

- Periodic Reapplication or Refreshing

Depending on the type of and the level of use, periodic reapplication or refreshing is necessary to maintain its protective qualities and appearance. Waxed surfaces, for example, require regular waxing to replenish the protective layer. Oil-based may benefit from occasional re-oiling to revitalize the wood and enhance its luster. Polyurethane-coated surfaces may require a complete refinishing after several years of wear. Ignoring this aspect of maintenance allows the protective layer to degrade, leaving the ash wood vulnerable to damage. Refinishing a worn dining table, for example, restores its original beauty and provides a renewed protective barrier against spills and scratches.

- Environmental Control

Maintaining a stable indoor environment helps prevent damage to the due to fluctuations in temperature and humidity. Extreme temperature swings can cause the wood to expand and contract, potentially leading to cracks or warping. High humidity promotes mold and mildew growth, which can stain or degrade the . Using a humidifier or dehumidifier, as needed, helps regulate moisture levels and prolong the life of the . Storing ash wood furniture away from direct sunlight prevents fading and discoloration. Consistent environmental control minimizes stress on the and the underlying wood, reducing the need for extensive repairs or refinishing.

In conclusion, a comprehensive maintenance strategy is crucial for preserving the beauty and durability of ash wood treated with a . Regular cleaning, surface protection, periodic reapplication, and environmental control work in concert to safeguard the integrity of the and ensure the long-term enjoyment of the finished product. Neglecting these aspects of maintenance leads to premature degradation and costly repairs, underscoring the importance of proactive and consistent care.

6. Sustainability

The integration of sustainability principles into the selection and application of wood surface treatments is increasingly critical. The environmental impact of these treatments extends from raw material sourcing to end-of-life disposal, necessitating a comprehensive evaluation of their ecological footprint. Traditional coatings often contain volatile organic compounds (VOCs) that contribute to air pollution and pose health risks. These factors drive the demand for sustainable alternatives, promoting practices that minimize environmental harm and conserve resources. The selection of a product that adheres to sustainable criteria affects the long-term ecological balance.

The practical application of sustainable coatings involves considering several factors. Water-based and plant-based options offer reduced VOC emissions compared to conventional solvent-based products. Certification programs, such as those offered by the Forest Stewardship Council (FSC), ensure responsible sourcing of raw materials used in their production. For instance, using a water-based polyurethane for furniture making reduces indoor air pollution and minimizes exposure to harmful chemicals. Similarly, employing finishes derived from renewable resources, such as linseed oil or beeswax, promotes a circular economy and reduces reliance on fossil fuels. Responsible disposal of waste materials generated during the application process is also essential.

Adopting sustainable practices in the treatment of ash wood is not without challenges. The performance characteristics of some eco-friendly options may not always match those of conventional counterparts, requiring careful consideration of the intended application and performance requirements. However, advancements in material science are continually improving the durability and aesthetic appeal of sustainable products. The integration of sustainability considerations into decision-making processes is essential for minimizing environmental impact and promoting a more responsible approach to wood finishing.

Frequently Asked Questions

This section addresses common inquiries and clarifies key aspects related to the selection, application, and maintenance of ash wood treatments.

Question 1: What are the primary advantages of applying a protective coating to ash wood?

A protective coating enhances durability, protects against moisture and UV damage, and improves the aesthetic appearance of the wood. It extends the lifespan of the wood and reduces the need for frequent repairs.

Question 2: How does the choice of impact the overall appearance of ash wood?

The type of applied determines the color, sheen, and grain enhancement of the wood. Clear coatings preserve the natural appearance, while tinted coatings alter the color. The chosen sheen level affects the reflectivity and visual texture of the surface.

Question 3: What surface preparation steps are necessary before applying a ?

Proper surface preparation includes sanding to achieve a smooth surface, cleaning to remove dust and contaminants, and potentially applying a wood conditioner to ensure uniform absorption. Failure to prepare the surface adequately can result in adhesion problems and an uneven appearance.

Question 4: How should one select a suitable for outdoor ash wood applications?

For outdoor applications, the should offer UV protection, water resistance, and resistance to mold and mildew. Select products specifically formulated for exterior use, and consider those that contain UV inhibitors to prevent fading and discoloration.

Question 5: What routine maintenance procedures are essential for preserving a coating?

Regular cleaning with appropriate cleaning agents is crucial. Using coasters and placemats, avoiding harsh chemicals, and addressing any scratches or damage promptly will also maintain the appearance and integrity of the treated surface.

Question 6: Are there environmentally friendly available for ash wood?

Yes, water-based and plant-based offer lower VOC emissions and are more sustainable than traditional solvent-based options. Look for products that are certified by recognized environmental organizations.

Understanding these aspects contributes to informed decision-making when selecting and maintaining ash wood finishes, ensuring both aesthetic appeal and long-term protection.

The following section will explore case studies and real-world applications demonstrating the effectiveness of proper application and maintenance techniques.

Conclusion

This exploration has detailed various facets of surface treatments on ash wood, encompassing durability, appearance, protection, application methods, maintenance protocols, and sustainability considerations. Selecting an appropriate type, applying it correctly, and maintaining the resulting surface are all essential factors in realizing the desired aesthetic and prolonging the lifespan of the treated wood.

Therefore, informed decisions are paramount. Continued adherence to best practices is strongly advised in order to guarantee lasting value and performance. This careful attention to detail promotes both the longevity and visual appeal of this valuable material.