Coatings applied to the surface of oak, a hardwood prized for its durability and grain, enhance its aesthetic appeal and provide protection. These treatments, available in a wide spectrum of colors and textures, are essential for preserving the integrity of the wood and achieving desired visual effects on furniture, flooring, and architectural elements.

The selection of an appropriate surface treatment is critical for safeguarding oak against moisture, scratches, and ultraviolet light, thereby extending its lifespan and maintaining its value. Historically, various oils and waxes were used; modern formulations include varnishes, lacquers, and polyurethane, offering superior resistance to environmental factors and ease of maintenance. This protective layer simultaneously elevates the wood’s inherent beauty, highlighting its grain patterns and contributing to the overall ambiance of a space.

Understanding the characteristics and applications of the many options available enables informed decision-making in design and construction. Subsequent sections will delve into specific types, application techniques, and considerations for selecting the optimal treatment for particular projects.

Tips for Enhancing Oak Surfaces

Proper treatment selection and application are crucial for maximizing the beauty and longevity of oak surfaces. The following guidance ensures optimal results in various applications.

Tip 1: Surface Preparation is Paramount. Prior to any application, the wood must be thoroughly sanded to create a smooth, even surface. Remove all dust and debris using a tack cloth or vacuum. This promotes proper adhesion and a uniform appearance.

Tip 2: Understand the Grain. Oak possesses a pronounced grain pattern that can be accentuated or subdued depending on the desired effect. Consider the direction of the grain when applying stains or sealers to ensure consistent absorption and prevent blotching.

Tip 3: Test Before Committing. Always test the chosen treatment on a small, inconspicuous area of the oak to verify the color and compatibility with the wood. Allow the test area to dry completely before evaluating the results.

Tip 4: Employ Multiple Thin Coats. Multiple thin coats of the selected product are generally preferable to a single thick coat. This method minimizes runs, drips, and air bubbles, resulting in a smoother and more durable surface.

Tip 5: Allow Adequate Drying Time. Adhere strictly to the manufacturer’s recommended drying times between coats. Insufficient drying can lead to adhesion problems and compromised durability.

Tip 6: Consider the Environment. The surrounding environment, including temperature and humidity, can significantly impact the application process. Avoid applying in extremely hot or humid conditions, as this can affect drying times and the final appearance.

Tip 7: Select the Correct Application Method. The choice of brush, spray gun, or rag applicator should be determined by the specific product and the desired finish. Experiment to determine the method that provides the most uniform and controlled application.

Following these guidelines ensures a professional and durable result, preserving the integrity and enhancing the natural beauty of oak.

The following sections will delve into specific types and their characteristics in detail, for optimum outcome.

1. Protection against elements

Surface treatments applied to oak play a vital role in shielding it from environmental factors. Unprotected oak is susceptible to damage from moisture, ultraviolet radiation, and temperature fluctuations. Moisture penetration can lead to swelling, warping, and fungal decay, significantly compromising the wood’s structural integrity. UV radiation causes fading and discoloration, diminishing its aesthetic appeal. Temperature variations induce expansion and contraction, potentially resulting in cracks and splits. Specific treatments form a barrier against these elements, preventing deterioration and prolonging the wood’s lifespan. For example, exterior doors benefit greatly from marine-grade varnishes due to their capacity to resist water intrusion and UV exposure. The selection of an appropriate protective layer is, therefore, paramount in safeguarding oak from environmental degradation.

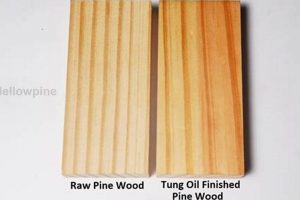

The effectiveness of a specific treatment depends on its composition and application. Penetrating oils, while enhancing the wood’s natural grain, offer limited protection against moisture and require frequent reapplication. Polyurethane coatings provide a more durable barrier but may alter the wood’s appearance. Film-forming treatments, like varnish and lacquer, create a robust shield against moisture and abrasion but can be prone to cracking if applied improperly. The choice should align with the anticipated environmental conditions and the desired aesthetic outcome. Consider a park bench, frequently exposed to the sun, rain, and snow. A robust, UV-resistant sealant is imperative in this scenario to avoid deterioration and maintain the bench’s function and visual appeal.

In summary, proper protection is not merely an aesthetic consideration but a crucial aspect of maintaining the structural soundness and longevity of oak. Selecting and applying suitable surface treatments offers indispensable protection against diverse environmental stressors. An understanding of the specific challenges posed by each element helps to inform the treatment selection process, contributing to the enduring value and beauty of the finished product. Future directions in material science may offer new options for the environmental protection of Oak.

2. Enhancement of grain

The interaction between treatments and oak’s inherent grain patterns represents a critical consideration in woodworking. The selection and application method either accentuates or subdues the natural figure, directly impacting the final aesthetic appeal of the finished piece. This process requires careful consideration of the desired visual outcome and the inherent characteristics of the wood.

- Highlighting Medullary Rays

Oak, particularly quarter-sawn oak, exhibits prominent medullary rays, which appear as shimmering flakes or lines across the surface. Certain penetrating oils and clear sealers are designed to accentuate these rays, enhancing the visual depth and complexity of the wood. For instance, a lightly tinted oil-based application can draw attention to these features without obscuring the natural color of the oak.

- Contrast Enhancement Through Staining

Staining can be employed to create contrast between the darker heartwood and lighter sapwood, or to emphasize the earlywood and latewood growth rings within the grain pattern. A darker stain will penetrate the more porous earlywood more readily, creating a distinct visual texture. Conversely, a lighter stain will subdue the contrast, resulting in a more uniform appearance.

- Textural Enhancement with Wire Brushing

Wire brushing techniques can physically alter the surface of the oak, removing the softer earlywood and leaving the denser latewood more prominent. This process creates a textured surface that emphasizes the grain pattern and provides a tactile dimension to the finished piece. Dark stains are often applied after wire brushing to further accentuate the raised grain.

- Preservation of Natural Color and Figure

In situations where the natural appearance of the oak is desired, clear, non-yellowing sealers are used to protect the wood while minimizing alterations to its color and grain pattern. Water-based acrylics or specialized UV-resistant coatings are often selected for this purpose, preserving the wood’s inherent beauty and preventing discoloration over time.

The strategic use of various techniques provides woodworkers with a range of options for manipulating the appearance of oak grain. The desired outcome whether a subtle enhancement of the natural figure or a dramatic alteration of its visual texture guides the selection and application process. Ultimately, the informed manipulation of grain patterns constitutes a key aspect of successful woodworking.

3. Color customization options

Surface treatments applied to oak provide extensive color customization possibilities. The natural hue of oak, which ranges from light beige to medium brown, serves as a neutral base that readily accepts a wide spectrum of stains and pigments. This adaptability enables the creation of diverse aesthetic effects, accommodating varied design preferences and architectural styles. The selection of a particular color transforms the appearance of oak, influencing the ambiance of a space and complementing surrounding elements. For example, a dark walnut stain on oak flooring introduces a sense of formality and sophistication, while a light, whitewashed application evokes a more casual and rustic feel. The capacity to alter the color of oak constitutes a significant advantage, enhancing its versatility and making it suitable for a broad range of applications.

The process of customizing the color of oak involves the application of penetrating stains, pigmented sealers, or toners. Penetrating stains infuse the wood fibers with pigment, altering the underlying color while allowing the grain pattern to remain visible. Pigmented sealers, on the other hand, deposit a layer of color on the surface of the wood, obscuring the grain pattern to varying degrees. Toners are translucent coatings used to adjust the overall tone of a finish without significantly altering the underlying color. The choice of application method, whether brushing, spraying, or wiping, also influences the final color and its uniformity. For instance, spraying often results in a more even and consistent color distribution compared to brushing, particularly on large surfaces. The effective manipulation of color relies on a thorough understanding of the properties of different stains and the techniques for applying them, contributing to design flexibility.

In summary, color customization options represent an integral component of surface treatments for oak, offering an unparalleled level of design flexibility. The ability to modify the appearance of oak allows it to seamlessly integrate into diverse settings and align with specific aesthetic goals. While challenges such as achieving consistent color matching and accounting for variations in wood density exist, the benefits of color customization far outweigh these obstacles. The vast array of available colors, combined with various application techniques, makes oak a highly adaptable material for both functional and decorative purposes, addressing a broad spectrum of architectural needs.

4. Durability and longevity

The relationship between surface treatments and the durability and longevity of oak represents a critical consideration for designers, builders, and consumers. The inherent properties of oak, such as its density and hardness, contribute to its natural resistance to wear and tear. However, the application of appropriate protective and enhancing treatments significantly extends its lifespan and preserves its structural and aesthetic integrity.

- Protection Against Moisture Intrusion

Moisture represents a primary threat to oak’s durability. Surface treatments, such as sealers and varnishes, create a barrier that prevents water from penetrating the wood fibers. This protection mitigates the risk of swelling, warping, and fungal decay, thereby preserving the dimensional stability and structural integrity of oak components in furniture, flooring, and exterior applications. Example: A properly sealed oak deck can withstand years of exposure to rain and snow without significant deterioration.

- Resistance to Abrasion and Wear

High-traffic areas, such as floors and countertops, subject oak to constant abrasion and wear. Durable surface coatings, such as polyurethane, provide a resilient layer that resists scratches, scuffs, and other forms of surface damage. This extends the lifespan of oak elements in these areas and maintains their aesthetic appeal over time. Example: Polyurethane-coated oak flooring in a busy household retains its appearance for many years with minimal maintenance.

- Prevention of Ultraviolet Degradation

Exposure to ultraviolet (UV) radiation from sunlight can cause oak to fade, discolor, and become brittle. UV-resistant treatments, such as specialized varnishes and sealers, incorporate UV absorbers that block or mitigate the harmful effects of sunlight. This is particularly important for oak used in exterior applications or in areas with high levels of sunlight exposure. Example: Spar varnish on oak trim protects it from sun damage.

- Enhancement of Insect Resistance

While oak possesses some natural resistance to insects, it can still be susceptible to attack by certain species, particularly in humid environments. Some surface treatments, such as those containing borates, provide an additional layer of protection against insect infestation. This helps to preserve the structural integrity of oak components and prevent costly damage. Example: Oak timbers treated with borate solutions are more resistant to termites.

These treatments contribute significantly to the long-term performance and sustainability of oak in diverse applications. The selection of appropriate treatments should be based on a careful consideration of the intended use, environmental conditions, and desired aesthetic outcome, ensuring that oak’s inherent durability and longevity are fully realized. Therefore, to obtain longevity, all things must be considered.

5. Maintenance requirements

The selection of treatments for oak directly dictates subsequent upkeep protocols. Different treatments require varying degrees of attention to preserve their protective and aesthetic qualities. Neglecting appropriate maintenance can lead to premature degradation, necessitating costly repairs or replacements. For instance, an oil-based surface treatment, while enhancing the wood’s natural grain, typically necessitates periodic reapplication to maintain its protective barrier against moisture. Conversely, a polyurethane surface treatment provides a more durable and water-resistant layer but requires less frequent maintenance. Thus, the initial choice of treatment creates a cascade of implications for long-term care, underscoring the importance of aligning treatment selection with practical maintenance capabilities.

Practical applications illustrate the significance of this relationship. Consider an oak floor treated with wax. This finish offers an appealing sheen but demands regular waxing and buffing to prevent scuffing and maintain its luster. Failure to adhere to this schedule results in a dull appearance and diminished protection against spills and abrasions. In contrast, an oak cabinet coated with lacquer resists scratches and requires only occasional cleaning with a mild detergent. These examples demonstrate that maintenance requirements must be weighed against the benefits of each treatment to determine the most suitable option for a specific application and the end-user’s willingness to commit to long-term care. Furthermore, understanding the specific cleaning agents and techniques recommended for each treatment prevents damage and extends its lifespan.

In summary, maintenance requirements are an inseparable aspect of surface treatments for oak. The level of upkeep required varies considerably depending on the type of treatment applied. Careful consideration of these requirements during the selection process ensures a balance between aesthetic preferences, desired performance characteristics, and practical maintenance capabilities. A proactive approach to maintenance, informed by an understanding of the chosen treatment’s properties, preserves the integrity and beauty of oak for years to come, minimizing long-term costs and maximizing its functional lifespan.

6. Application Techniques Importance

Effective application techniques are paramount in achieving optimal results when treating oak surfaces. The chosen method significantly impacts the appearance, durability, and longevity of the surface coating. Improper application can negate the benefits of even the highest-quality finish, resulting in aesthetic flaws, compromised protection, and accelerated deterioration. Therefore, a thorough understanding of appropriate application methodologies is indispensable.

- Surface Preparation and Cleanliness

Proper surface preparation is fundamental. Sanding to the appropriate grit level, followed by thorough dust removal, ensures optimal adhesion and a smooth, uniform finish. Contaminants such as oil, wax, or residual sanding dust inhibit proper bonding, leading to peeling, blistering, or uneven color absorption. The implementation of meticulous surface preparation protocols represents a critical first step in achieving a professional and durable outcome.

- Selection of Application Tools

The choice of application toolbrush, sprayer, or wiping clothdirectly affects the quality of the finish. Brushes are suitable for detailed work and penetrating oils, while sprayers provide a more even application for lacquers and varnishes on large surfaces. Wiping cloths are often used for applying stains and glazes, allowing for controlled color saturation. The correct tool, selected based on the properties of the finish and the project requirements, contributes to a smoother, more consistent, and visually appealing result.

- Environmental Control During Application

Environmental conditions, particularly temperature and humidity, exert a significant influence on the drying and curing process. Elevated humidity levels can prolong drying times, leading to runs, sags, and a hazy appearance. Extreme temperatures can cause finishes to dry too quickly, resulting in brush marks, air bubbles, or a rough texture. Maintaining a controlled environment within the manufacturer’s recommended parameters is crucial for ensuring proper film formation and optimal durability.

- Adherence to Recommended Application Rates

Applying the correct amount of finish, as specified by the manufacturer, is essential for achieving the desired level of protection and aesthetic appearance. Applying too little finish results in inadequate coverage and reduced durability, while applying too much leads to runs, drips, and a soft, uncured film. Careful attention to application rates, typically measured in mils or dry film thickness, ensures that the finish performs as intended and provides long-lasting protection against environmental factors.

In conclusion, the skillful execution of application techniques directly influences the success of any treatment. The quality of wood treatments is only as good as the means of its application. By adhering to best practices in surface preparation, tool selection, environmental control, and application rates, one can maximize the beauty, durability, and longevity of an oak surface, ensuring a lasting investment.

Frequently Asked Questions

This section addresses common queries regarding the selection, application, and maintenance of coatings for oak, providing informative responses to ensure optimal preservation and enhancement of this valuable wood.

Question 1: What surface treatments provide the most durable protection for oak flooring in high-traffic areas?

Polyurethane-based coatings offer superior resistance to abrasion and moisture, making them well-suited for oak flooring subjected to heavy foot traffic. Multiple coats, properly applied, provide a resilient and long-lasting protective layer.

Question 2: How does the choice of affect the long-term maintenance requirements of oak furniture?

The selected treatment significantly impacts ongoing maintenance needs. Oil-based finishes require periodic reapplication, while lacquer or varnish finishes necessitate less frequent attention, primarily involving cleaning with appropriate products.

Question 3: Which treatment is most appropriate for preserving the natural color and grain of oak while providing adequate protection against UV radiation?

Water-based acrylic sealers containing UV inhibitors are recommended for preserving the natural appearance of oak while mitigating the damaging effects of sunlight. These sealers offer a clear, non-yellowing protective layer.

Question 4: What steps are necessary to ensure proper adhesion of surface treatments to oak, preventing peeling or blistering?

Thorough surface preparation is essential. This includes sanding the oak to a smooth, even surface, removing all dust and contaminants, and applying a compatible primer or sealer to promote proper adhesion of the finish coat.

Question 5: How does humidity affect the application and curing of surface treatments on oak, and what precautions should be taken?

High humidity levels can impede the drying process, leading to runs, sags, and a cloudy appearance. It is advisable to apply surface treatments in a controlled environment with moderate humidity and adequate ventilation, adhering to the manufacturer’s recommended drying times.

Question 6: Can surface treatments be used to enhance the natural grain patterns of oak, and if so, which treatments are most effective?

Penetrating oils and stains can effectively accentuate the grain patterns of oak. Oil-based applications often enhance the depth and richness of the grain, while stains provide opportunities to introduce color contrast and highlight specific features.

Proper understanding of the properties, application, and maintenance requirements ensures the successful protection and enhancement of oak.

The next section will discuss the enviornmental effect of oak.

Conclusion

The preceding discussion elucidated the critical role of surface treatments in preserving and enhancing oak. Durability, aesthetic appeal, and long-term maintenance requirements are all significantly influenced by the appropriate selection and application of specific protectants. Key factors, including protection against environmental elements, grain enhancement, color customization, and longevity, necessitate careful consideration in any project involving this versatile hardwood.

A commitment to informed decision-making, grounded in a thorough understanding of both the inherent properties of oak and the characteristics of available protectants, is paramount. Continued advancements in coating technology promise to further extend the lifespan and versatility of oak, solidifying its position as a material of enduring value and aesthetic significance in diverse applications.