The process involves applying a colored liquid to a wooden surface to alter its appearance. This liquid penetrates the wood pores, imparting a hue that enhances the grain and character of the material. For instance, a light-colored wood like pine can be transformed to resemble a richer tone like cherry or mahogany.

This surface treatment serves multiple purposes. It enhances the aesthetic appeal of wooden objects, offering a wide range of color choices to match desired design schemes. Furthermore, it provides a degree of protection against sunlight and moisture, contributing to the longevity of the treated wood. Historically, such treatments have been employed to mimic the look of more expensive woods, providing an economical alternative while preserving and beautifying the underlying material.

Understanding the nuances of wood preparation, application techniques, and the types of products available is essential for achieving a professional and lasting result. The subsequent sections will delve into these aspects, providing a detailed guide to achieving optimal outcomes in wood finishing projects.

Essential Guidelines for Color Infusion and Surface Treatment

Achieving a desirable outcome necessitates meticulous attention to detail throughout the entire process. The following guidelines provide a framework for success.

Tip 1: Surface Preparation is Paramount: Sand the wood thoroughly, progressing through increasingly finer grits of sandpaper. Remove all dust with a tack cloth. A smooth, clean surface ensures even absorption of the coloring agent.

Tip 2: Select the Appropriate Product Type: Oil-based, water-based, and gel formulations each possess unique characteristics. Oil-based generally offer longer working times and richer hues, while water-based options are known for their low odor and easy cleanup. Gel products are ideal for vertical surfaces or woods prone to blotching.

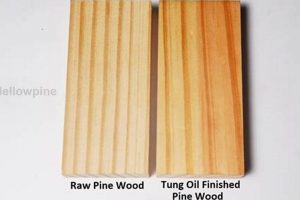

Tip 3: Test Color Before Committing: Apply the chosen product to a small, inconspicuous area or a scrap piece of the same wood. This step allows for evaluation of the final appearance and adjustment of the color if necessary. Allow the test area to fully dry before assessing.

Tip 4: Apply Evenly and Sparingly: Use a high-quality brush, rag, or foam applicator. Apply the product in thin, even coats, following the grain of the wood. Avoid applying too much at once, as this can lead to uneven color and prolonged drying times.

Tip 5: Wipe Off Excess Product: Allow the product to penetrate for the manufacturer’s recommended time, then wipe off any excess with a clean, lint-free cloth. Wiping ensures that the color is evenly distributed and prevents a sticky or glossy finish.

Tip 6: Allow Adequate Drying Time: Follow the manufacturer’s instructions regarding drying times. Rushing this step can lead to imperfections in the final finish and adhesion problems with subsequent coats.

Tip 7: Consider a Sealer or Topcoat: Applying a clear sealer or topcoat protects the treated surface and enhances its durability. Choose a product compatible with the product used to impart color. Polyurethane, lacquer, and varnish are common choices.

Adhering to these guidelines will maximize the aesthetic appeal and longevity of wooden projects. The subsequent sections will discuss specialized techniques and advanced considerations.

1. Color Penetration

Color penetration is a fundamental aspect of imparting color to wood. The effectiveness of penetration determines the uniformity, depth, and longevity of the final appearance. Understanding the factors that influence color penetration is critical for achieving the desired aesthetic result and ensuring the durability of the finish.

- Wood Porosity and Grain Structure

The inherent porosity and grain structure of different wood species significantly affect the degree to which a coloring agent can permeate the material. Open-grained woods, such as oak and ash, tend to absorb more readily, resulting in deeper color penetration. Conversely, closed-grained woods, such as maple and cherry, exhibit reduced absorption, potentially leading to a more superficial color application. The choice of product and application technique must consider these variations to ensure even color distribution.

- Surface Preparation Techniques

Adequate surface preparation is paramount for promoting optimal color penetration. Sanding removes surface imperfections and opens the wood pores, allowing the coloring agent to penetrate more effectively. Failure to sand properly can result in uneven color absorption and a blotchy or inconsistent finish. Furthermore, the removal of dust and debris from the surface is crucial, as these contaminants can impede penetration and compromise the adhesion of the coloring agent.

- Product Formulation and Solvent Type

The specific formulation of the coloring agent and the type of solvent used play a significant role in determining the depth and uniformity of penetration. Oil-based products generally offer deeper penetration compared to water-based products, owing to the ability of oil to dissolve and carry pigments further into the wood fibers. The solvent acts as a carrier for the pigment, influencing its ability to permeate the wood. Consideration must be given to the compatibility of the product with the specific wood species being treated.

- Application Method and Technique

The method of application and the technique employed directly influence the amount of coloring agent that is absorbed by the wood. Applying the product in thin, even coats, followed by wiping off excess, allows for controlled penetration and prevents the formation of a thick, superficial layer. Brushing, spraying, and wiping are common application methods, each offering varying degrees of control over penetration. The chosen technique should be tailored to the specific product and the desired aesthetic outcome.

The interplay between wood properties, preparation techniques, product characteristics, and application methods directly impacts the extent of color penetration. Understanding and carefully managing these factors is essential for maximizing the aesthetic appeal and ensuring the long-term durability of a treated wooden surface.

2. Surface Protection

Surface protection represents a critical phase in the process of treating wood with coloring agents. It safeguards the underlying material from environmental factors and physical damage, thereby prolonging the lifespan and maintaining the aesthetic integrity of the treated surface. Without adequate surface protection, the effects of coloring agents are inherently vulnerable to degradation, necessitating frequent reapplication and potentially compromising the structural integrity of the wood itself.

- Moisture Resistance

Surface protection frequently involves the application of water-resistant coatings. These coatings prevent moisture absorption, which can lead to warping, swelling, and cracking of the wood. In environments with high humidity or exposure to precipitation, moisture resistance is paramount. For example, exterior wooden furniture requires a robust, water-resistant finish to withstand the elements. Failure to provide adequate moisture resistance can result in premature deterioration of the wood and the loss of the coloring agent.

- UV Radiation Shielding

Exposure to ultraviolet (UV) radiation from sunlight can cause the fading and discoloration of coloring agents, as well as the degradation of the wood surface itself. Protective coatings containing UV absorbers mitigate these effects by filtering out harmful radiation. This is particularly important for items such as wooden decks and siding, which are constantly exposed to direct sunlight. Without UV protection, the color imparted by the treatment can fade rapidly, necessitating frequent reapplication to maintain the desired aesthetic.

- Abrasion Resistance

The application of durable topcoats provides resistance to abrasion and physical wear. This is particularly important for surfaces that experience frequent contact or friction, such as wooden floors and tabletops. Abrasion-resistant coatings prevent scratches, scuffs, and other forms of surface damage, preserving the integrity of the finish and the underlying treatment. Without sufficient abrasion resistance, the treated surface is susceptible to damage, which can detract from its aesthetic appeal and reduce its lifespan.

- Chemical Resistance

Certain environments expose wood surfaces to various chemicals, such as cleaning agents, solvents, and acids. Protective coatings with chemical resistance prevent these substances from damaging or discoloring the finish. This is especially important in kitchens and laboratories, where wooden surfaces are likely to come into contact with a variety of chemicals. Failure to provide adequate chemical resistance can result in staining, etching, or other forms of damage to the treated surface.

The application of protective coatings following the application of coloring agents is integral to preserving the appearance and longevity of treated wood. These coatings provide a barrier against moisture, UV radiation, abrasion, and chemical exposure, thereby maintaining the integrity of the finish and the underlying wood. Choosing the appropriate protective coating depends on the intended use of the treated item and the environmental conditions to which it will be exposed.

3. Grain Enhancement

The use of coloring agents on wood often serves the purpose of accentuating the natural grain patterns inherent in the material. The visibility and prominence of the grain directly influence the aesthetic appeal of the finished product. Certain woods, such as oak or ash, possess pronounced grain patterns that can be dramatically highlighted through the selective absorption of coloring agents. Conversely, woods with subtler grain structures may require specific techniques to enhance their visual interest. The interaction between the coloring agent and the wood’s cellular structure dictates the degree to which the grain is emphasized. Lighter shades of coloring agents tend to highlight grain patterns subtly, while darker shades create a more dramatic contrast, effectively deepening the visual texture of the wood. This effect is commonly observed in furniture making, where the inherent beauty of the wood grain is a primary design consideration.

Achieving effective grain enhancement relies on several factors. Proper sanding and surface preparation are crucial to ensure uniform absorption of the coloring agent. Techniques such as pre-raising the grainwetting the wood slightly before sandingcan further enhance the visibility of the grain pattern. The choice of application method also plays a significant role. Wiping is often preferred over brushing, as it allows for better control over the amount of coloring agent that remains on the surface, thereby accentuating the grain rather than obscuring it. For instance, applying a dark wiping to oak cabinets highlights the open grain pattern, creating a rich, textured appearance that is highly desirable in interior design.

Effective grain enhancement through the application of coloring agents requires an understanding of both the wood’s inherent properties and the characteristics of the coloring agent itself. Careful consideration of these factors, combined with proper preparation and application techniques, results in a finished product that showcases the natural beauty of the wood. The challenge lies in achieving a balance between enhancing the grain and maintaining the wood’s natural character, a balance that distinguishes skilled craftsmanship from mere surface treatment. Ultimately, the successful enhancement of wood grain contributes significantly to the perceived value and aesthetic appeal of the finished article.

4. Application Technique

The efficacy of finishing wood with a coloring agent is intrinsically linked to the application technique employed. The method through which the material is applied directly influences the uniformity of color, depth of penetration, and overall aesthetic quality of the final product. Suboptimal application can result in uneven color distribution, blotching, or a finish that lacks the desired durability.

- Brush Application and Control

The utilization of a brush necessitates precise control to ensure an even layer of coloring agent is distributed across the wood surface. Factors such as brush type (natural vs. synthetic bristles), brush size, and the angle of application influence the final outcome. For instance, applying a coloring agent with long, overlapping strokes minimizes the appearance of brush marks, while using a brush that is too large can lead to excessive application and potential dripping. Inconsistent brushwork often results in noticeable variations in color intensity across the finished surface.

- Wiping Technique and Absorption

The wiping technique, commonly employed to remove excess coloring agent, directly impacts the depth of color penetration and the prominence of the wood grain. The timing of wiping, the material used for wiping (lint-free cloth), and the pressure applied all contribute to the final appearance. Wiping too soon after application can remove too much coloring agent, resulting in a pale or uneven finish. Conversely, delaying the wiping process can lead to a darker, more saturated color, potentially obscuring the wood grain. Careful attention to these details is crucial for achieving the desired aesthetic effect.

- Spraying Methods and Uniformity

Spraying, whether with an airless sprayer or HVLP (High Volume Low Pressure) system, offers the potential for a highly uniform finish. However, achieving this uniformity requires careful calibration of the sprayer, proper viscosity of the coloring agent, and consistent spray patterns. Overlapping spray passes are essential to avoid light spots or streaking. Inadequate preparation or improper technique can lead to runs, drips, or an uneven texture on the wood surface. Precise control over these variables is necessary to realize the benefits of spraying.

- Gel Applications for Vertical Surfaces

Gel formulations are often favored for vertical surfaces due to their non-drip characteristics. However, the application of gel products requires a different approach compared to liquid treatments. Gel treatments must be applied evenly to prevent pooling and ensure uniform color distribution. The use of specialized applicators, such as foam pads or staining cloths, can facilitate the application process. Failure to apply gel evenly can result in blotching or a finish that appears uneven in texture and color.

The selection and execution of the application technique are integral to the successful finishing of wood with a coloring agent. Each method possesses unique advantages and disadvantages, requiring careful consideration of the wood species, the type of coloring agent being used, and the desired aesthetic outcome. Mastery of these techniques elevates the finishing process from a mere surface treatment to a skilled craft.

5. Product Selection

The selection of appropriate products is paramount when executing any wood finishing endeavor involving coloring agents. The choice directly influences the aesthetic outcome, the durability of the finish, and the ease with which the process can be completed. A well-informed decision requires careful consideration of several factors, each impacting the final result.

- Type of Coloring Agent: Oil-Based vs. Water-Based

Oil-based products are known for their deep penetration and rich color tones, often preferred for hardwoods and projects where depth of color is crucial. However, they typically exhibit longer drying times and require solvent-based cleanup. Water-based products offer faster drying times, lower odor, and easier cleanup, making them suitable for projects requiring a quicker turnaround and in environments where solvent fumes are a concern. The specific needs of the project and the environment should guide this decision.

- Colorant Formulation: Liquid vs. Gel

Liquid products are commonly used for general applications, providing ease of application and even coverage on flat surfaces. Gel formulations excel on vertical surfaces or woods prone to blotching, as their viscous consistency prevents running and promotes uniform absorption. For intricate carvings or complex wood grain patterns, gels may offer superior control and prevent undesirable pooling or dripping.

- Topcoat Compatibility and Protection Level

The topcoat selected must be chemically compatible with the coloring agent used to ensure proper adhesion and prevent undesirable reactions such as lifting or discoloration. Furthermore, the level of protection offered by the topcoat should align with the intended use of the finished product. High-traffic surfaces, such as floors or tabletops, require durable topcoats with abrasion and chemical resistance, while decorative items may only require a sealant for moisture protection and enhanced aesthetic appeal.

- Wood Conditioner and Pre-Treatment Options

For certain wood species prone to uneven absorption, such as pine or cherry, the use of a wood conditioner or pre-treatment is essential to ensure uniform color penetration and prevent blotching. These products seal the wood pores, creating a more consistent surface for the coloring agent to adhere to. The selection of a suitable pre-treatment should be based on the specific characteristics of the wood being treated and the type of product being applied.

The relationship between product selection and successful wood finishing is undeniable. By carefully considering the properties of the wood, the desired aesthetic, and the environmental conditions to which the finished product will be exposed, one can make informed choices that lead to professional-quality results and ensure the long-term durability and beauty of the treated wood.

Frequently Asked Questions

The subsequent queries address common points of concern and misconceptions encountered during the process of imparting color and protection to wooden surfaces.

Question 1: What distinguishes a gel coloring agent from a liquid variant, and when is each most suitable?

Gel formulations exhibit a higher viscosity compared to liquid counterparts. This characteristic renders them particularly effective on vertical surfaces, mitigating the risk of drips and runs. Furthermore, gel products are often preferred for woods prone to blotching, as their consistency promotes more uniform absorption. Liquid treatments are generally suitable for horizontal surfaces and woods that readily accept color.

Question 2: Is sanding always necessary prior to applying color?

Sanding is generally considered essential for achieving optimal results. The process removes surface imperfections, opens the wood pores, and promotes uniform absorption of the coloring agent. However, the specific grit and sanding technique should be tailored to the wood species and the desired aesthetic outcome. Failure to sand properly can lead to uneven color distribution and a compromised finish.

Question 3: What is the significance of wiping off excess product after application?

Wiping off excess material serves several critical functions. It ensures that the coloring agent is evenly distributed across the surface, prevents the formation of a sticky or glossy film, and enhances the visibility of the wood grain. The timing of wiping is crucial; wiping too soon can remove too much of the coloring agent, while delaying the process can result in a darker, less desirable tone.

Question 4: How does the choice of topcoat impact the long-term durability of the finish?

The topcoat provides a protective barrier against moisture, UV radiation, abrasion, and chemical exposure. Selecting a topcoat that is specifically formulated for the intended use of the finished item is essential for maximizing its lifespan. High-traffic surfaces require more durable topcoats with enhanced abrasion resistance, while items exposed to direct sunlight necessitate topcoats with UV inhibitors.

Question 5: Can different coloring agents be mixed to achieve custom hues?

Mixing different coloring agents to achieve custom hues is possible, but it requires caution and careful consideration. The compatibility of the formulations must be verified to prevent undesirable reactions, such as settling or separation. It is advisable to test the mixture on a small, inconspicuous area before applying it to the entire project. Furthermore, detailed records of the mixing ratios should be maintained for future reference.

Question 6: How does temperature and humidity affect the drying time and final appearance?

Elevated humidity levels and lower temperatures generally prolong the drying time of both coloring agents and topcoats. These conditions can also affect the final appearance, potentially leading to a cloudy or uneven finish. Maintaining a stable and controlled environment is conducive to achieving optimal results. Adhering to the manufacturer’s recommendations regarding temperature and humidity is crucial for ensuring proper drying and a durable finish.

These inquiries represent a fraction of the considerations involved. Diligent research and experimentation are encouraged for achieving mastery.

The subsequent section will explore advanced techniques and specialized applications.

Conclusion

The preceding discussion has explored the multifaceted process of imparting color and protective finishes to wood. Key aspects examined include the influence of wood species, the selection of appropriate materials, the significance of meticulous surface preparation, the nuances of application techniques, and the importance of appropriate topcoat selection. The interrelation of these factors dictates the final aesthetic outcome and the long-term durability of the treated surface.

Effective execution of wood finishing transcends mere application of coloring agents. It demands a comprehensive understanding of material science, chemical interactions, and skilled craftsmanship. The pursuit of mastery in this discipline yields not only aesthetically pleasing results but also the preservation and enhancement of a valuable and renewable resource. Continued research and refinement of techniques remain essential for advancing the art and science of wood finishing.