The concluding stage in woodworking involves applying protective and aesthetic coatings to wooden items. This process enhances the durability and appearance of pieces such as tables, chairs, and cabinets. Common techniques include staining to alter color, sealing to prevent moisture absorption, and top coating for a resilient surface.

Proper implementation of this concluding process preserves wooden items, shielding them from environmental factors like humidity and ultraviolet radiation. It improves longevity and can enhance the aesthetic value, aligning pieces with specific design preferences or historical styles. This final step significantly impacts the overall value and utility of the finished product.

The subsequent sections will detail various methods employed, materials required, and best practices for achieving professional-quality outcomes on wooden furniture.

Essential Guidelines for Final Wood Surface Treatment

Achieving a professional-grade outcome necessitates careful attention to detail and adherence to established procedures. The following guidelines aim to improve the quality and longevity of wooden furniture.

Tip 1: Surface Preparation: Thoroughly sand the wood surface, progressing through increasingly finer grits of sandpaper. Remove all dust and debris before any coatings are applied. Proper preparation ensures uniform absorption and adhesion of subsequent layers.

Tip 2: Consistent Stain Application: Apply stain evenly, working in the direction of the wood grain. Excess stain should be wiped away promptly to avoid blotching or uneven coloration. Multiple thin coats are preferable to a single heavy coat.

Tip 3: Sealer Selection: Choose a sealer compatible with both the stain used and the topcoat intended. The sealer’s primary function is to create a uniform surface for the topcoat, preventing absorption into the wood and enhancing the final finish.

Tip 4: Topcoat Application Technique: Apply topcoats in thin, even layers, allowing each layer to dry completely before applying the next. Avoid drips and runs by maintaining a consistent distance and speed during application.

Tip 5: Environmental Control: Apply coatings in a well-ventilated area with controlled temperature and humidity. Extreme temperatures or high humidity can affect the drying time and overall quality of the resultant surface.

Tip 6: Adequate Drying Time: Allow sufficient drying time between coats and before placing the furniture into service. Rushing the drying process can compromise the durability and appearance of the treated surface.

Effective treatment relies on diligent preparation, meticulous application, and a controlled environment. Following these guidelines will contribute to a robust, aesthetically pleasing, and long-lasting result.

The subsequent section will address specific considerations for selecting appropriate products and materials.

1. Surface Preparation

The initial stage, surface preparation, is paramount in achieving a successful outcome in final wood treatment. Improperly prepared surfaces can result in adhesion failures, uneven color absorption, and compromised structural integrity of the coating. For example, if residual sanding dust remains on the wood, the coating will not bond correctly, leading to premature chipping or peeling. Similarly, inconsistencies in sanding can cause stain to absorb unevenly, resulting in a blotchy or inconsistent appearance. The quality of the concluding layer is directly contingent upon the meticulousness of the surface work.

Effective surface preparation encompasses several key steps. The initial step involves coarse sanding to remove imperfections and level the wood surface. Subsequent sanding with progressively finer grits refines the surface, creating a smooth and receptive substrate for coatings. Following sanding, thorough dust removal is essential. Techniques such as vacuuming and tack cloth wiping ensure a clean surface, free from particles that could interfere with adhesion. In some cases, a solvent wipe may be necessary to remove oils or waxes that could prevent proper coating adherence.

In summary, surface preparation constitutes a critical prerequisite for achieving desired results. It directly impacts the adhesion, appearance, and longevity of the implemented coatings. Ignoring surface work results in defects, diminished protection, and a reduced overall lifespan for the finished wooden pieces. Therefore, adequate time and effort must be allocated to this initial stage to achieve the high quality standard.

2. Product Selection

Product selection significantly influences the outcome of the finishing process of wooden furniture. The choice of materials, including stains, sealers, and topcoats, directly affects the aesthetic properties, durability, and long-term maintenance requirements of the finished piece. For example, employing a water-based stain on a surface intended for high-moisture environments, such as a bathroom vanity, may result in premature coating failure due to inadequate moisture resistance. Conversely, utilizing a high-VOC solvent-based topcoat in an area with stringent air quality regulations could lead to environmental compliance issues and health concerns.

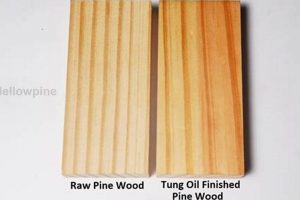

Understanding the specific characteristics of each product category is crucial. Stains vary in pigment composition, penetration depth, and drying time, affecting the final color and grain enhancement. Sealers, such as shellac, lacquer, or polyurethane, create a barrier between the wood and the topcoat, influencing adhesion and preventing uneven absorption. Topcoats provide the final protective layer, offering varying levels of scratch resistance, UV protection, and sheen. Selecting compatible products is essential to prevent issues like blistering, cracking, or delamination.

The careful selection of appropriate materials is essential for achieving durable, aesthetically pleasing, and environmentally responsible wooden furniture surface treatments. It is a decision-making process that should consider the intended use of the furniture, the environmental conditions it will endure, and the desired aesthetic outcome. Neglecting the product selection component risks compromising the long-term integrity and visual appeal of the finished article.

3. Application Technique

The method of applying concluding layers to wooden furniture significantly impacts the final appearance, durability, and overall quality of the piece. Deviations from established techniques can result in defects, diminished protection, and a compromised aesthetic.

- Spraying Techniques

Spraying provides a consistent and even coating, particularly suitable for complex surfaces. The uniformity of the applied coating minimizes the potential for drips, runs, or brush marks. Success hinges on proper equipment calibration, consistent spray distance, and appropriate fluid viscosity. Inconsistent spray patterns or inadequate atomization can lead to an uneven finish, requiring additional sanding and reapplication.

- Brushing Techniques

Brushing is suitable for smaller projects or areas where precise control is needed. Selecting the correct brush type, maintaining a wet edge, and applying even pressure are critical. Improper brushing can result in visible brush strokes, uneven thickness, and air bubbles trapped in the coating. Careful attention to detail is crucial to achieve a professional result.

- Wiping Techniques

Wiping techniques are primarily used for applying stains, glazes, and certain types of sealers. The goal is to achieve consistent color saturation and highlight the wood grain. Excess material must be removed promptly and evenly to prevent blotching or streaking. The type of wiping cloth used and the direction of the wipe significantly influence the final appearance.

- Layering and Drying

Applying multiple thin layers, with proper drying time between each coat, promotes superior adhesion and durability. Rushing the drying process can lead to trapped solvents, which can compromise the finish and cause clouding or cracking. Following the manufacturer’s recommended drying times is essential to ensure a fully cured and resilient coating.

The connection between application technique and the ultimate success of wooden furniture concluding underscores the importance of skilled execution. Each technique presents specific challenges and requires diligent practice to master. Consistent, careful execution directly correlates with an enhanced final product.

4. Environmental Conditions

Environmental conditions exert a profound influence on the successful completion of surface treatments for wooden furniture. Temperature, humidity, and air quality each contribute significantly to the adhesion, drying, and overall integrity of applied coatings. Fluctuations or extremes in these environmental variables can precipitate a range of issues, including improper drying, surface imperfections, and compromised structural integrity. For instance, elevated humidity levels can impede the evaporation of solvents in coatings, leading to prolonged drying times and the potential for a milky or clouded finish. Similarly, low temperatures can increase viscosity, hindering proper flow and leveling of the coating, resulting in brush marks or an orange-peel texture.

Maintaining optimal environmental conditions is therefore critical for achieving a professional-quality result. Recommended temperature and humidity ranges vary depending on the specific coatings being used, but generally, a stable temperature between 65F and 75F (18C and 24C) and a relative humidity between 40% and 60% are considered ideal. Air quality also plays a crucial role; dust and other airborne particles can contaminate the wet coating, leading to surface imperfections. Adequate ventilation and the use of air filtration systems can minimize this risk. Controlling these factors requires a dedicated workspace, equipped with appropriate climate control and air filtration mechanisms. Without such controls, outcomes risk being unpredictable and of diminished quality.

In conclusion, environmental conditions are integral to the surface concluding of wooden furniture. Understanding and diligently managing temperature, humidity, and air quality are not merely best practices, but essential prerequisites for ensuring durable, aesthetically pleasing, and long-lasting outcomes. Overlooking these variables can negate even the most meticulous surface preparation and application techniques. Thus, integrating stringent environmental control measures is a crucial element in achieving professional results.

5. Cure Time

Cure time, the period required for a applied coating to achieve its optimal hardness, durability, and chemical resistance, is a critical factor in surface treatments of wooden furniture. Insufficient cure time can compromise the finish, leading to a range of problems that affect the longevity and aesthetic appeal of the completed piece.

- Solvent Evaporation

Many coatings contain solvents that must fully evaporate for the coating to harden. Premature use or handling of the finished piece prevents proper solvent release, resulting in a soft or tacky surface. This can lead to fingerprints, dust adherence, and an increased susceptibility to scratches and abrasions. Failure to allow sufficient solvent evaporation undermines the intended protective qualities of the surface work.

- Polymer Cross-Linking

The curing process often involves chemical reactions, such as polymer cross-linking, which strengthens the coating. Inadequate cure time arrests these reactions, resulting in a finish that is less durable and more prone to damage. For example, a polyurethane finish that has not fully cured will be more susceptible to scratching and chipping, reducing its ability to protect the underlying wood.

- Chemical Resistance Development

Full cure time is necessary for the coating to achieve its maximum resistance to chemicals and solvents. Exposure to cleaning agents or spills before the coating is fully cured can lead to staining, discoloration, or even dissolution of the finish. This is particularly important for furniture intended for use in kitchens or dining areas, where exposure to liquids and cleaning products is common.

- Adhesion Enhancement

The bond between the coating and the wood surface strengthens during the curing process. Shortened cure times can compromise adhesion, increasing the likelihood of peeling, blistering, or delamination. This is especially crucial for surfaces that will be subjected to heavy use or significant temperature fluctuations.

The relationship between cure time and surface integrity is direct and significant. Adhering to the manufacturer’s recommended cure times, typically found on product labels, is essential for realizing the full benefits of the chosen surface. Deviation from these guidelines, regardless of perceived expediency, can result in premature coating failure and reduced longevity of the furniture piece. Patience during the curing process is therefore an investment in the long-term quality and protection of the treated wood.

Frequently Asked Questions

This section addresses common inquiries and concerns regarding the surface treatment of wooden furniture. Accurate information promotes successful outcomes and extends the lifespan of wood articles.

Question 1: What determines the durability of surfaces?

Durability depends upon the selection of appropriate materials, meticulous surface preparation, proper application techniques, and adherence to recommended cure times. Environmental factors during application also play a significant role.

Question 2: How does surface preparation affect quality?

Surface preparation, including sanding and cleaning, removes imperfections, creates a receptive surface for coatings, and ensures proper adhesion. Neglecting this stage results in uneven finishes and premature failure.

Question 3: What considerations govern product selection?

Product selection requires careful consideration of stain type, sealer compatibility, and topcoat characteristics. The intended use of the furniture and the environmental conditions to which it will be exposed should dictate the choice of products.

Question 4: Why is the application technique important?

The application technique ensures uniform coating thickness, minimizes imperfections, and maximizes adhesion. Techniques vary depending on the material used, but consistent execution is always essential.

Question 5: How do environmental conditions influence the process?

Temperature, humidity, and air quality influence the drying time, adhesion, and overall quality. Maintaining stable and appropriate environmental conditions is crucial for achieving optimal results.

Question 6: Why is sufficient cure time necessary?

Cure time allows coatings to achieve maximum hardness, durability, and chemical resistance. Rushing the cure process results in a compromised finish that is susceptible to damage.

Proper surface treatment of wooden furniture relies upon a comprehensive understanding of materials, techniques, and environmental factors. Diligence and patience are key to achieving long-lasting and aesthetically pleasing outcomes.

The subsequent section provides a glossary of common terms associated with furniture surface treatment.

Concluding Remarks

This exploration has illuminated the critical aspects of finishing wood furniture, encompassing surface preparation, product selection, application methodologies, environmental controls, and cure times. Attention to these detailed processes determines the durability, aesthetic quality, and overall longevity of wooden creations. Effective surface treatment is therefore more than a mere concluding step; it represents a fundamental investment in the preservation and enhancement of wooden articles.

Continued adherence to established best practices, coupled with ongoing research into innovative materials and techniques, will further elevate the art and science of finishing wood furniture. A commitment to excellence in this domain ensures the enduring beauty and functionality of wooden pieces for generations to come.