Prepared wooden boards, ready for installation, represent a popular choice in construction and design. These materials undergo a process of smoothing, sealing, and often staining or painting, resulting in a surface that is both aesthetically pleasing and protected from wear. Examples range from flooring and wall paneling to furniture components and decorative elements, each showcasing the inherent grain and texture of the underlying lumber.

The appeal of such materials stems from their durability, natural beauty, and versatility. They add warmth and character to interior spaces, while also offering a relatively easy-to-maintain surface. Historically, these elements have been employed in building for centuries, reflecting a long-standing appreciation for the strength and elegance of timber. Furthermore, they enhance property value and contribute to a sustainable building practice when sourced responsibly.

The following discussion will delve into the various types of wood used in manufacturing these items, the different finishing techniques employed, considerations for installation and maintenance, and finally, the environmental impact of their production and disposal.

Essential Considerations for Prepared Wood Boards

The selection and installation of pre-treated wood surfaces require careful attention to detail to ensure longevity and aesthetic appeal. Adherence to best practices minimizes future issues and maximizes the value of the investment.

Tip 1: Acclimation is Crucial. Allow the material to adjust to the installation environment for several days prior to fitting. This minimizes expansion and contraction issues post-installation, preventing warping or gaps.

Tip 2: Substrate Preparation Matters. Ensure the subfloor or wall surface is level, clean, and dry. Imperfections in the underlying surface will be amplified, leading to unevenness and potential damage.

Tip 3: Proper Fastening Techniques are Essential. Employ the correct type and size of fasteners for the specific wood species and application. Over-tightening or using inappropriate fasteners can damage the material.

Tip 4: Moisture Control is Paramount. Maintain consistent humidity levels within the building to prevent excessive swelling or shrinkage. Employ dehumidifiers or humidifiers as needed to stabilize the environment.

Tip 5: Select Appropriate Cleaning Products. Use only cleaning agents specifically designed for wood surfaces. Harsh chemicals can damage the finish and degrade the material over time.

Tip 6: Consider Professional Installation. While DIY installation is possible, professional installers possess the expertise and tools to ensure proper fitting and alignment, minimizing errors and maximizing the lifespan of the product.

Tip 7: Routine Inspection is Advised. Regularly inspect the surface for signs of damage, wear, or moisture intrusion. Addressing issues promptly prevents escalation and costly repairs.

By implementing these guidelines, one can ensure the successful application and long-term preservation of prepared wood surfaces, resulting in a durable and aesthetically pleasing environment.

The subsequent sections will explore specific types of wood treatments and maintenance schedules tailored to different applications.

1. Wood Species Selection

The selection of wood species is a foundational decision in the creation of durable and aesthetically appropriate prepared wood boards. It directly influences the material’s performance characteristics, appearance, and ultimately, its suitability for specific applications.

- Hardness and Durability

Different wood species exhibit varying degrees of hardness, measured by the Janka hardness scale. Harder woods, such as oak, maple, and hickory, are more resistant to scratches, dents, and wear, making them ideal for high-traffic areas like flooring. Softer woods, such as pine or fir, may be more susceptible to damage but can be suitable for decorative applications or areas with less foot traffic. The intended use case dictates the necessary hardness of the selected wood.

- Grain Pattern and Aesthetic

Each species possesses a unique grain pattern that contributes significantly to the visual appeal of prepared boards. Oak, for example, exhibits a prominent grain pattern that is often desired for its classic and traditional look. Maple features a finer, more uniform grain, suitable for modern and minimalist designs. Cherry wood is known for its rich, reddish-brown color and smooth texture, enhancing a sense of elegance. The aesthetic requirements of the project drive the selection of a species with a corresponding grain pattern.

- Dimensional Stability

Dimensional stability refers to a wood’s ability to resist shrinking or swelling in response to changes in humidity. Species like teak and cedar possess natural oils that enhance their resistance to moisture, making them suitable for outdoor applications or areas prone to humidity fluctuations. Less stable species, like pine or birch, require careful sealing and environmental control to prevent warping or cracking. Understanding the environmental conditions of the installation site is crucial for choosing a species with adequate dimensional stability.

- Workability and Cost

The ease with which a wood can be cut, shaped, and finished influences the overall cost of the prepared boards. Softer woods are generally easier to work with and therefore less expensive. Harder woods require more specialized tools and techniques, increasing production costs. The budget constraints of the project must be balanced against the desired performance characteristics and aesthetic qualities of the selected species.

In summary, the wood species selection is a multi-faceted decision that necessitates careful consideration of the intended application, environmental conditions, aesthetic preferences, and budgetary constraints. A well-informed choice ensures the creation of prepared boards that are both durable and visually appealing, contributing to the overall success of the project.

2. Finishing Process Quality

The caliber of the finishing process profoundly impacts the performance, longevity, and aesthetic appeal of prepared wood boards. It is not merely a superficial treatment but rather a critical step that determines the material’s resistance to environmental factors, wear, and overall structural integrity.

- Surface Preparation

Proper surface preparation is paramount before the application of any finish. This involves sanding to achieve a smooth, uniform surface, removing imperfections such as scratches or blemishes, and ensuring the wood is free from dust or contaminants. Inadequate preparation leads to uneven finish absorption, compromised adhesion, and a visually unappealing final product. For instance, failing to properly sand before staining can result in blotchy or inconsistent color absorption.

- Application Technique

The method of application significantly influences the quality of the finish. Techniques such as spraying, brushing, or rolling each have their advantages and disadvantages. Spraying provides a consistent and even coat, while brushing allows for greater control over application in intricate areas. Regardless of the chosen method, proper technique is crucial to avoid issues such as drips, runs, or brush marks. Skilled application ensures uniform coverage and maximizes the protective properties of the finish.

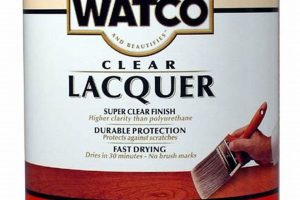

- Type of Finish Material

The selection of the appropriate finish material is critical for achieving the desired performance characteristics. Options include varnishes, lacquers, polyurethanes, oils, and waxes, each offering varying levels of protection against moisture, scratches, and UV radiation. For example, polyurethane provides excellent durability and water resistance, making it suitable for flooring applications. The wrong choice of finish can lead to premature wear, discoloration, or even damage to the underlying wood.

- Curing and Drying Conditions

Proper curing and drying conditions are essential for the finish to achieve its full protective properties. Temperature, humidity, and air circulation all play a critical role in the curing process. Insufficient drying time can result in a soft, tacky finish that is easily damaged. Conversely, excessively high temperatures or low humidity can cause the finish to crack or bubble. Controlled environmental conditions during curing are necessary to ensure a durable and long-lasting finish.

In essence, the quality of the finishing process is a holistic measure encompassing surface preparation, application technique, material selection, and curing conditions. A meticulous approach to each of these elements is vital for maximizing the value and lifespan of prepared wood boards, ensuring they meet both aesthetic and functional requirements.

3. Installation Environment Factors

The environment where prepared wood boards are installed exerts a substantial influence on their long-term performance and appearance. Controlling these factors is critical for mitigating potential damage and ensuring the material’s longevity.

- Humidity Levels

Fluctuations in humidity represent a primary concern. Wood is hygroscopic, meaning it absorbs and releases moisture from the surrounding air. Excessive humidity leads to swelling, potentially causing boards to warp, buckle, or develop mold. Conversely, low humidity causes shrinkage, resulting in gaps between boards and potential cracking. Maintaining a stable humidity level, ideally between 30% and 50%, is crucial for preserving the dimensional stability of wood surfaces. As an example, installation in a bathroom without adequate ventilation will expose the boards to high humidity, leading to premature degradation.

- Temperature Variations

Significant temperature changes can also affect prepared wood surfaces. Rapid temperature fluctuations cause expansion and contraction, leading to stress within the material. Over time, this stress can result in cracking, splitting, or delamination of the finish. Maintaining a consistent temperature within the building, avoiding extreme temperature swings, will minimize these risks. Instances such as direct exposure to sunlight through a window can cause localized overheating and subsequent damage to the board.

- Sunlight Exposure

Prolonged exposure to direct sunlight can cause fading or discoloration of prepared wood boards. Ultraviolet (UV) radiation breaks down the pigments in the finish, leading to a gradual loss of color. In addition, sunlight can cause the wood itself to dry out, making it more susceptible to cracking and splitting. Using UV-resistant finishes or installing window coverings to reduce sunlight exposure can mitigate these effects. A south-facing wall, receiving intense afternoon sun, exemplifies an area requiring careful consideration for UV protection.

- Airflow and Ventilation

Adequate airflow and ventilation are essential for preventing moisture buildup and promoting even drying of the material. Stagnant air can trap moisture, creating an environment conducive to mold and mildew growth. Proper ventilation helps to dissipate moisture and maintain a consistent humidity level throughout the building. Poor ventilation in a basement, for example, can lead to moisture accumulation and subsequent damage to prepared wood surfaces.

Considering these environmental factors during installation is paramount to maintaining the integrity and aesthetic appeal of prepared wood boards. Implementing appropriate preventative measures will ensure the long-term performance and value of the investment.

4. Maintenance requirements understanding

A comprehensive understanding of maintenance requirements is fundamentally linked to the preservation and longevity of prepared wood boards. The finish applied to these boards, while offering initial protection, necessitates ongoing care tailored to its specific properties and the environmental conditions. Failure to recognize and address these maintenance needs precipitates a cascade of negative effects, diminishing both the aesthetic appeal and structural integrity of the wood.

For instance, neglect of oiled wood surfaces leads to dryness and cracking, requiring re-oiling to replenish the protective barrier. Conversely, inappropriate cleaning of polyurethane-coated boards with abrasive chemicals compromises the finish, leaving the wood vulnerable to moisture damage and staining. A fundamental aspect of this understanding involves recognizing the appropriate cleaning agents, frequency of application, and methods required for the specific finish type. Furthermore, awareness of potential hazards, such as excessive moisture or direct sunlight, and the implementation of preventative measures, constitutes a critical component of responsible stewardship.

The practical significance of understanding maintenance needs extends beyond mere aesthetic considerations. Timely intervention prevents costly repairs or replacements, preserving the value of the investment. Routine cleaning removes dirt and grime that can abrade the finish, while prompt attention to scratches or dents prevents further damage and potential structural weakness. In essence, a proactive approach to maintenance, grounded in knowledge of the material’s specific requirements, ensures the continued beauty and functionality of prepared wood boards.

5. Aesthetic considerations importance

The visual characteristics of prepared wooden surfaces are of paramount importance, playing a decisive role in shaping the overall ambiance and perceived value of interior spaces. This facet significantly influences the selection process and contributes substantially to the satisfaction derived from the installed material.

- Color Palette Integration

The color of prepared wooden elements must harmonize with the broader color scheme of the room. A mismatch can create visual dissonance, detracting from the intended aesthetic. For instance, dark wood floors in a brightly lit, modern room may appear out of place, while lighter tones may enhance the sense of spaciousness. Successful integration enhances the visual appeal and creates a cohesive design.

- Grain Pattern and Texture

The natural grain pattern and texture of the wood contribute significantly to its visual character. A pronounced grain can add warmth and rustic charm, while a smoother, more uniform surface offers a contemporary and refined look. Choosing the appropriate grain and texture ensures alignment with the desired style and enhances the overall visual impact of the space. A rough-sawn texture, for example, may be suitable for a farmhouse-style interior, while a finely sanded and polished surface complements a minimalist aesthetic.

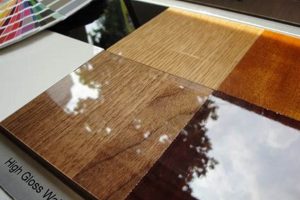

- Finish Gloss Level

The gloss level of the finish affects the way light reflects off the surface, influencing the perceived depth and richness of the wood. A high-gloss finish provides a reflective, luxurious appearance, while a matte finish offers a more subdued and natural look. The selection of the appropriate gloss level depends on the desired aesthetic and the intended use of the space. High-gloss finishes are often used in formal dining rooms, while matte finishes are more common in bedrooms and living areas.

- Board Width and Layout

The width of the boards and the layout pattern significantly impact the visual appeal of the installation. Wider boards create a sense of spaciousness and can enhance the natural grain pattern, while narrower boards offer a more traditional and intricate look. The layout pattern, such as straight, diagonal, or herringbone, adds visual interest and can influence the perceived size and shape of the room. Diagonal layouts, for example, can make a small room appear larger, while herringbone patterns add a touch of elegance and sophistication.

In conclusion, aesthetic considerations represent a critical element in the selection and application of prepared wooden boards. Thoughtful attention to color, grain, finish, and layout ensures a visually harmonious and aesthetically pleasing result that enhances the overall value and enjoyment of the space. The careful selection creates harmony between materials used and end-user preference.

6. Structural Integrity Evaluation

The assessment of structural integrity is paramount when considering prepared wood boards for various applications. The ability of these elements to withstand imposed loads and environmental stressors directly dictates their suitability and long-term performance. A rigorous evaluation process is essential to ensure safety, prevent premature failure, and maximize the lifespan of the installation.

- Species-Specific Strength Properties

Different wood species exhibit varying degrees of strength and stiffness. Evaluation involves referencing established data, such as those provided by organizations like the USDA Forest Products Laboratory, to determine the allowable bending stress, shear strength, and modulus of elasticity for the selected species. These values are critical for calculating load-bearing capacity and ensuring the wood can withstand anticipated forces. For example, oak possesses significantly higher strength properties compared to pine, making it a more suitable choice for structural applications requiring high load resistance. The improper application of softwood in load-bearing applications can result in catastrophic failure.

- Defect Identification and Assessment

Visual inspection and non-destructive testing methods are employed to identify and assess defects that can compromise structural integrity. Knots, grain deviations, checks, and splits all weaken the wood and reduce its ability to withstand stress. The size, location, and orientation of these defects are carefully evaluated to determine their impact on load-bearing capacity. For instance, a large knot located near the center of a beam significantly reduces its bending strength, while a series of small checks may have a negligible effect. Standards such as those published by the American Wood Council provide guidelines for assessing the allowable size and frequency of defects in structural lumber.

- Moisture Content Influence

The moisture content of prepared wood boards significantly affects their strength and stiffness. As moisture content increases, the wood becomes weaker and more flexible. Evaluation involves measuring the moisture content using a moisture meter and adjusting the allowable design stresses accordingly. Building codes typically specify maximum allowable moisture content levels for structural lumber. For example, lumber installed in a humid environment will have a higher moisture content and lower strength properties compared to lumber installed in a dry environment. Neglecting to account for moisture content can lead to underestimation of the actual stresses and potential structural failure.

- Finish Impact on Load Capacity

While the finish primarily serves an aesthetic and protective function, certain coatings can influence the structural behavior of prepared wood boards. Some finishes, particularly those that are very rigid, can increase the stiffness of the wood, while others can reduce its ability to absorb impact loads. Evaluation involves considering the properties of the finish material and its potential impact on the overall structural performance of the element. For example, applying a thick, inflexible coating to a wood beam may increase its stiffness but also make it more brittle and susceptible to cracking under high loads. The impact is generally less than 5 percent of load capacity, however.

These considerations highlight the importance of integrating structural assessment procedures into the utilization of finished wood materials. The confluence of species selection, defect analysis, moisture levels, and applied coatings shapes the overall performance and stability of the chosen wooden solutions. The information is crucial for long lasting, reliable construction.

Frequently Asked Questions

This section addresses common inquiries regarding the selection, application, and maintenance of prepared wood boards, providing concise and informative answers to ensure optimal performance and longevity.

Question 1: What constitutes a prepared wood board, and how does it differ from raw lumber?

Prepared wood boards represent lumber that has undergone processing beyond basic milling. This includes surfacing (planing), shaping (e.g., tongue and groove), and the application of a protective and/or decorative finish. Raw lumber, in contrast, is simply sawn timber that requires further processing before use.

Question 2: What factors should influence the selection of wood species for prepared boards in a high-traffic area?

For areas subject to heavy use, wood species selection should prioritize hardness, durability, and resistance to wear. Hardwoods such as oak, maple, or hickory are generally preferable to softer woods like pine or fir, due to their greater resistance to dents, scratches, and abrasion.

Question 3: What are the primary advantages of factory-applied finishes compared to applying finishes on-site?

Factory-applied finishes offer several advantages, including controlled environmental conditions, consistent application, and rapid curing. These factors contribute to a more durable and uniform finish compared to on-site applications, which are susceptible to environmental variables and potential inconsistencies in technique.

Question 4: How should prepared wood boards be acclimated prior to installation to mitigate dimensional changes?

Prior to installation, prepared wood boards must be acclimated to the environmental conditions of the installation site. This involves storing the boards in the intended installation area for several days, allowing them to adjust to the temperature and humidity levels. Adequate acclimation minimizes expansion and contraction after installation, preventing warping or gapping.

Question 5: What cleaning agents are appropriate for maintaining the finish on prepared wood boards, and which should be avoided?

Maintenance requires the use of cleaning agents specifically formulated for wood surfaces. Harsh chemicals, abrasive cleaners, and excessive moisture should be avoided, as they can damage the finish and degrade the underlying wood. A mild, pH-neutral cleaner applied with a soft cloth is generally recommended.

Question 6: How can prepared wood boards be protected from excessive sunlight exposure to prevent fading or discoloration?

Protection from excessive sunlight exposure involves implementing measures to reduce the intensity of ultraviolet (UV) radiation. These measures may include the application of UV-resistant finishes, the installation of window coverings (e.g., blinds or curtains), or the use of UV-filtering window film.

In summary, informed decision-making regarding the selection, installation, and maintenance of prepared wood boards is essential for maximizing their performance, longevity, and aesthetic appeal. Attention to factors such as wood species, finish quality, acclimation, and environmental conditions will contribute to a successful and enduring installation.

The following section will provide a glossary of terms relevant to prepared wood boards, offering definitions and explanations to enhance understanding of key concepts and terminology.

Concluding Remarks

This exploration has underscored the multifaceted nature of prepared wood surfaces. The selection of appropriate species, meticulous attention to finishing processes, control of installation environment factors, adherence to maintenance protocols, appreciation for aesthetic considerations, and rigorous evaluation of structural integrity are all indispensable elements for maximizing the value and lifespan of these materials. The discussed factors impact overall quality.

The utilization of prepared wood surfaces represents a significant investment, demanding informed decision-making and diligent stewardship. A continued commitment to best practices will ensure the enduring beauty, functionality, and structural soundness of these materials, contributing to both the aesthetic and economic value of the built environment. Further research and development in sustainable wood sourcing and advanced finishing technologies will undoubtedly shape the future of this industry.