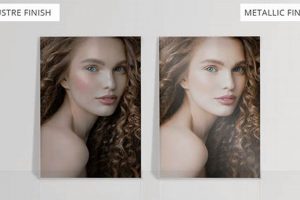

A surface treatment applied to metallic materials imparts a distinctive visual texture characterized by subtle, diffused reflections. This results in a softer, less reflective appearance compared to highly polished or mirrored surfaces. An example includes stainless steel appliances commonly found in kitchens, where the subdued sheen provides a contemporary aesthetic while minimizing fingerprint visibility.

The application of this surface treatment enhances the aesthetic appeal and functional properties of metal components. It effectively hides minor imperfections and scratches, contributing to increased durability and ease of maintenance. Its adoption has expanded across various industries, from architecture and automotive design to consumer electronics, driven by the demand for visually appealing and robust materials.

The following discussion will delve into the specific techniques used to achieve this distinctive surface, exploring the range of metals suitable for this treatment, and considering the factors influencing its selection for various applications.

Guidance on Maintaining the Integrity of the Surface

Adhering to these guidelines will preserve the characteristic appearance and extend the lifespan of the treated material.

Tip 1: Implement Regular Cleaning Protocols: Routine cleaning with mild soap and water is recommended to remove surface contaminants and prevent the accumulation of dirt and grime. Avoid abrasive cleaners that can scratch or damage the refined texture.

Tip 2: Employ Appropriate Cleaning Implements: Utilize soft cloths or sponges for cleaning. Refrain from using scouring pads or wire brushes, as these can alter the intended appearance.

Tip 3: Minimize Exposure to Harsh Chemicals: Prolonged contact with strong acids, alkalis, or solvents should be avoided, as these substances may corrode or discolor the treated surface. Promptly wipe away any spills to prevent permanent damage.

Tip 4: Implement Protective Measures in High-Traffic Areas: In environments with high levels of physical contact, consider applying a protective coating or film to minimize the risk of scratches and abrasions.

Tip 5: Conduct Periodic Inspections: Regularly examine the surface for signs of damage, such as scratches, corrosion, or discoloration. Address any issues promptly to prevent further degradation.

Tip 6: Consider Professional Refinishing: For significant damage or extensive wear, consult a professional refinisher. They can restore the surface’s original appearance and texture.

By following these recommendations, the integrity and aesthetic qualities of the surface will be preserved, ensuring long-term satisfaction.

The following section will explore the different applications and industries that leverage this surface treatment.

1. Aesthetics

The application of a specific surface treatment profoundly influences the visual character of metallic components. The resulting subdued reflectivity creates a perception of sophistication and elegance, making it a sought-after choice in diverse design applications. This aesthetic appeal stems from the diffusion of light, minimizing glare and creating a softer visual experience. The preference for this treatment in areas requiring a refined appearance, such as high-end consumer electronics and architectural interiors, directly illustrates the importance of aesthetic considerations.

The impact of this surface on aesthetics extends beyond mere visual appeal. It effectively conceals minor surface imperfections, contributing to a more uniform and visually pleasing texture. This characteristic is particularly valuable in applications where surface defects are unacceptable, such as in luxury automotive interiors. Furthermore, the subdued nature of the surface allows surrounding design elements to take prominence, avoiding visual competition and fostering a cohesive aesthetic. For example, custom metal hardware with a subdued finish in a designer kitchen allows the cabinetry and countertops to be the focal point, enhancing the overall design intent.

In conclusion, the aesthetic properties of this surface treatment are integral to its widespread adoption. Its ability to impart a refined, understated elegance while minimizing visual distractions makes it a versatile choice for designers and manufacturers seeking to create visually appealing and sophisticated products. Challenges in its implementation may include achieving consistent uniformity across large surfaces; however, the aesthetic benefits generally outweigh these considerations, ensuring its continued relevance in design applications that prioritize visual harmony and refinement.

2. Durability

Durability is a critical consideration in material selection, particularly regarding surface treatments. A surface’s resilience dictates its lifespan and performance under varying environmental and mechanical conditions. When applied to metal, a specific surface treatment can significantly enhance its resistance to wear, corrosion, and other forms of degradation, directly impacting its suitability for diverse applications.

- Enhanced Scratch Resistance

The described surface, due to its textured nature, effectively masks minor scratches and abrasions that would be highly visible on a polished surface. This inherent property prolongs the aesthetic appeal of the material in high-contact environments. For instance, stainless steel elevator panels treated in this manner maintain their visual integrity despite frequent use.

- Improved Corrosion Resistance

The application of this treatment can, under certain circumstances, contribute to increased corrosion resistance. By creating a more uniform surface, the treatment can reduce the number of sites where corrosion is likely to initiate. This is particularly relevant in outdoor architectural applications, where metal components are exposed to moisture and pollutants.

- Reduced Fingerprint Visibility

The textured finish effectively minimizes the visibility of fingerprints and smudges. This attribute reduces the need for frequent cleaning and maintenance, contributing to the long-term preservation of the material’s appearance. Consumer appliances, such as refrigerators and dishwashers, often benefit from this characteristic.

- Impact Resistance

While not inherently increasing the metal’s resistance to deformation from significant impacts, the surface treatment can prevent superficial damage from becoming more severe. Scratches and dents that might otherwise lead to corrosion or weakening of the material are often less likely to propagate from the textured surface. This is a significant factor in the selection of materials for automotive interiors and other high-wear applications.

These factors collectively demonstrate that a specific surface finish significantly contributes to the overall durability of metal components. The enhancement of scratch resistance, potential improvement in corrosion resistance, reduction in fingerprint visibility, and mitigation of damage propagation all underscore the importance of this surface treatment in extending the lifespan and maintaining the aesthetic appeal of metallic materials across various industries.

3. Maintenance

The upkeep requirements of materials with specific surface treatments are a primary factor influencing their selection for diverse applications. This consideration is particularly relevant where sustained aesthetic appeal and functional integrity are essential, as it directly affects long-term costs and user satisfaction.

- Routine Cleaning Procedures

The textured surface inherent in this finish reduces the visibility of minor smudges and fingerprints, requiring less frequent and intensive cleaning compared to highly polished surfaces. Typical maintenance involves wiping with a soft, damp cloth and a mild, non-abrasive detergent. In contrast, mirrored surfaces often necessitate specialized cleaning solutions and meticulous polishing to maintain their pristine appearance. For example, elevator interiors treated with this finish require less frequent cleaning cycles than those with mirrored stainless steel, thereby reducing labor costs and downtime.

- Resistance to Abrasive Damage

While not impervious to damage, surfaces of this type exhibit a greater tolerance for minor abrasions. Light scratches are less noticeable due to the existing texture, mitigating the need for immediate repair or refinishing. This contrasts with highly polished surfaces, where even minor imperfections are readily apparent and necessitate immediate attention. A practical example is found in high-traffic areas, such as retail environments, where fixtures with this treatment retain their aesthetic appeal for a longer duration, reducing the need for costly replacements or repairs.

- Mitigation of Corrosion Effects

The maintenance regimen for this surface aims to prevent the onset of corrosion. Regular cleaning removes corrosive agents and prevents the accumulation of grime that can accelerate deterioration. Surfaces left unmaintained are prone to localized corrosion, particularly in environments with high humidity or exposure to salts. For instance, architectural elements treated with this finish require periodic cleaning to remove atmospheric pollutants and prevent the formation of rust, ensuring long-term structural integrity and aesthetic consistency.

The comparatively lower maintenance demands associated with this surface treatment present a significant advantage in applications where ease of upkeep and long-term cost efficiency are paramount. Its inherent resistance to visual imperfections and its tolerance for less frequent cleaning cycles contribute to reduced operational expenses and increased user satisfaction across various industries.

4. Reflection

The degree to which a surface reflects light is a defining characteristic. In materials featuring this particular surface treatment, reflection is purposefully subdued. Unlike highly polished or mirrored surfaces, which exhibit specular reflection (where light rays bounce off in a coherent direction), the treatment introduces a diffuse reflection. This occurs because the surface is microscopically textured, scattering light in multiple directions. The practical effect is a softer, less glaring appearance, reducing visual fatigue and enhancing the aesthetic quality of the material. In control panels for industrial machinery, for example, this reduced reflectivity minimizes glare, improving readability and operator comfort.

The control over reflection afforded by this surface is crucial for both functional and aesthetic reasons. The reduced glare makes surfaces easier to view in brightly lit environments. Moreover, the diffused reflection minimizes the visibility of imperfections, such as scratches and fingerprints, which are more readily apparent on highly reflective surfaces. Consider architectural hardware: door handles, push plates, and kick plates frequently employ this treatment to maintain a clean and professional appearance despite frequent handling. The balance between sufficient illumination and glare reduction is a key engineering consideration, with the specific degree of texture carefully calibrated to achieve the desired reflective properties.

In summary, the connection between a metal’s surface and reflection is defined by a deliberate alteration of the way light interacts with the material. The diffused reflection achieved through this treatment balances aesthetic appeal with practical functionality, mitigating glare and reducing the visibility of surface imperfections. While the manufacturing process demands careful control to ensure consistent reflective properties, the benefits in terms of visual comfort and long-term appearance preservation are significant and directly contribute to its wide application in diverse industries.

5. Cost

The economic dimension of employing a surface treatment on metal materials necessitates careful consideration of initial expenses versus long-term value. The cost associated with achieving this surface involves several factors, including the specific metal alloy, the chosen application method, and the scale of production. Initial costs may be higher than those for simpler finishing techniques, such as basic painting or leaving the metal untreated. However, this increased initial investment must be weighed against potential long-term cost savings related to reduced maintenance, increased durability, and enhanced aesthetic appeal.

The application method significantly impacts the final cost. Abrasive blasting, for instance, requires specialized equipment and skilled labor, thereby increasing the initial investment. However, the resulting surface texture can effectively mask imperfections and provide a uniform finish. Conversely, chemical etching may offer a lower initial cost but could necessitate stringent environmental controls and waste disposal procedures, potentially leading to unforeseen expenses. The choice of metal also plays a crucial role. Stainless steel, while offering inherent corrosion resistance, is generally more expensive than carbon steel, impacting the overall project budget. Real-world examples include architectural firms weighing the upfront cost of stainless steel railings with this finish against the long-term maintenance costs associated with painted carbon steel, particularly in coastal environments prone to corrosion. The initial higher expenditure on stainless steel often proves economically advantageous over the lifespan of the structure.

In conclusion, the integration of this surface treatment into metal fabrication involves a nuanced interplay between initial costs and long-term economic benefits. While the upfront investment may be higher compared to simpler finishes, the enhanced durability, reduced maintenance requirements, and sustained aesthetic appeal often result in significant cost savings over the product’s lifecycle. A thorough cost-benefit analysis, considering factors such as material selection, application method, and environmental conditions, is essential for making informed decisions that optimize both economic value and functional performance.

6. Applications

The versatility of a specific surface treatment extends across numerous industries and product categories. Its selection is predicated on the desired balance between aesthetics, durability, and cost-effectiveness. The following details highlight common applications, illustrating the reasons for its adoption and the benefits it provides.

- Consumer Appliances

Household appliances such as refrigerators, dishwashers, and ovens frequently employ this surface treatment on stainless steel components. The finish minimizes fingerprint visibility and smudges, maintaining a cleaner appearance with less frequent cleaning. This characteristic is particularly valued in kitchens and other high-traffic areas. Example: A stainless steel refrigerator with this treatment retains its aesthetic appeal despite constant handling.

- Architectural Hardware

Door handles, push plates, and kick plates often feature this surface due to its scratch resistance and ability to conceal minor imperfections. The understated appearance complements a wide range of design styles. Example: Commercial buildings often utilize door hardware with this finish to withstand heavy use while maintaining a professional appearance.

- Automotive Interiors

Trim pieces, dashboard components, and control panels within automobiles benefit from this surface’s glare reduction and scratch resistance. The finish provides a sophisticated look while minimizing distractions for the driver. Example: Dashboard trim with this surface maintains visibility in bright sunlight, improving safety and driver comfort.

- Electronics Casings

The exterior housings of electronic devices, such as laptops and smartphones, may incorporate this surface to provide a durable and visually appealing finish. The treatment resists scratches and fingerprints, contributing to a premium product feel. Example: A laptop with this finish offers a more professional appearance and withstands the rigors of daily use.

The widespread adoption of this surface treatment underscores its adaptability and value proposition. Its ability to enhance both the functional and aesthetic qualities of metal components makes it a preferred choice across a diverse spectrum of applications.

Frequently Asked Questions Regarding Surfaces Exhibiting a Specific Metallic Treatment

The following addresses common inquiries concerning the properties, applications, and maintenance of surfaces with a distinctive metallic finish.

Question 1: Is this surface treatment suitable for outdoor applications exposed to harsh weather conditions?

The suitability depends on the specific metal alloy and the severity of the environmental conditions. While the treatment itself offers some protection by masking imperfections, the underlying metal’s inherent corrosion resistance is the primary factor. Stainless steel alloys generally perform well outdoors, whereas carbon steel may require additional protective coatings.

Question 2: Can this type of finish be applied to all types of metals?

While the technique can be applied to a wide range of metals, certain alloys are more amenable to achieving a uniform and consistent surface. Aluminum, stainless steel, and brass are commonly treated, while some less common alloys may present challenges in achieving the desired effect.

Question 3: Does this surface treatment affect the metal’s structural integrity?

The treatment itself typically has a negligible impact on the metal’s structural properties. The process primarily affects the surface layer and does not significantly alter the bulk material’s strength or load-bearing capacity. However, excessive abrasion or harsh chemical treatments could potentially weaken the surface.

Question 4: How does this surface compare to a brushed finish in terms of maintenance requirements?

The maintenance requirements are generally similar. Both finishes benefit from routine cleaning with mild soap and water. However, the specific texture of each finish may influence the visibility of fingerprints and smudges. Surfaces of this type tend to conceal minor imperfections more effectively than brushed surfaces.

Question 5: Is it possible to repair scratches or damage on a surface with a specific metallic finish?

Minor scratches can often be blended or masked using specialized polishing compounds designed for metals. However, deeper scratches or significant damage may require professional refinishing to restore the original appearance. The feasibility of repair depends on the severity and extent of the damage.

Question 6: What are the primary factors influencing the cost of achieving this surface treatment?

The cost is influenced by several factors, including the type of metal, the size and complexity of the component, the chosen application method, and the volume of production. More intricate surface preparation techniques and specialized equipment will generally result in higher costs.

In summary, a clear understanding of these nuances enables informed decision-making when selecting materials and surface treatments for diverse applications.

The subsequent section will analyze the role of industry standards.

Conclusion

The preceding discussion has explored various facets of surfaces with a specific metallic treatment, encompassing its aesthetic qualities, durability characteristics, maintenance considerations, reflective properties, cost implications, and diverse applications. The analysis has revealed that achieving this finish involves a deliberate manipulation of the metal surface to balance visual appeal with functional performance.

Ultimately, the selection of materials and surface treatments requires careful evaluation of project-specific requirements and budgetary constraints. The insights provided herein should inform decision-making processes, enabling stakeholders to leverage the benefits of this technology while mitigating potential challenges. Continued research and development in surface engineering will undoubtedly lead to further advancements in this field, expanding its applications and enhancing its performance characteristics.