Surface treatment applied to manufactured goods enhances their properties and appearance. This process, often involving coating or modification of the outer layer, is critical for a wide range of materials, from metals and plastics to wood and composites. Examples include painting metal components to prevent corrosion, applying a protective layer to plastic parts for improved durability, or polishing surfaces to achieve a desired aesthetic.

The significance of these techniques lies in their ability to increase product lifespan, improve functionality, and add value. Historically, surface treatment provided basic protection; however, modern advancements deliver specialized functionalities such as resistance to extreme temperatures, enhanced electrical conductivity, or antimicrobial properties. These treatments are pivotal in sectors ranging from automotive and aerospace to construction and consumer goods, impacting both performance and market appeal.

The following sections will delve into specific methods employed, examine the factors influencing process selection, and discuss the latest innovations driving advancements in the field of surface modification and protection.

Guidelines for Effective Application

Achieving optimal outcomes requires careful planning and execution. The following guidelines outline essential considerations for ensuring quality and longevity of treated surfaces.

Tip 1: Material Compatibility: Thoroughly evaluate the compatibility between the base material and the chosen treatment. Incompatible combinations can lead to adhesion failures, compromised protection, or accelerated degradation. For example, certain acidic pretreatments may damage sensitive aluminum alloys.

Tip 2: Surface Preparation: Proper surface preparation is paramount. Contaminants such as oil, grease, and oxides must be removed to ensure adequate adhesion. Methods include solvent cleaning, abrasive blasting, and chemical etching, each tailored to the specific material and contaminant.

Tip 3: Controlled Application Parameters: Precise control of application parameters, such as temperature, pressure, and coating thickness, is crucial. Deviations can result in inconsistent coverage, defects, or reduced performance. Automated application systems can improve consistency and reduce variability.

Tip 4: Environmental Considerations: Be mindful of environmental regulations and choose environmentally responsible processes. Alternatives to chromate conversion coatings, for example, are gaining increasing acceptance due to their reduced environmental impact.

Tip 5: Testing and Quality Control: Implement rigorous testing and quality control procedures to verify that the treatment meets specified performance requirements. Standard tests include adhesion testing, corrosion resistance testing, and thickness measurement.

Tip 6: Proper Curing and Drying: Adhere to recommended curing or drying schedules to achieve optimal film properties. Insufficient curing can result in soft, easily damaged coatings, while excessive curing can lead to brittleness.

Tip 7: Maintenance and Inspection: Establish a routine maintenance and inspection program to identify and address any signs of deterioration early on. This will help to extend the lifespan of the treated surface and prevent costly repairs.

Adherence to these principles will contribute to enhanced durability, performance, and aesthetic appeal of manufactured goods, maximizing return on investment. Furthermore, it will ensure compliance with environmental standards.

The subsequent discussions will explore case studies and examine emerging technologies that further optimize practices.

1. Corrosion Protection

Corrosion protection is inextricably linked to many surface treatment processes. The deterioration of materials, especially metals, due to environmental factors poses significant economic and safety challenges across industries. Processes involved in surface treatment are often designed to provide a barrier between the substrate material and corrosive agents, such as moisture, salts, and pollutants. The effectiveness of any treatment is directly proportional to its ability to prevent or slow down the corrosion process. Examples include applying a protective layer of zinc through galvanization on steel structures to prevent rust, or using specialized epoxy coatings on pipelines to protect against corrosive chemicals in the oil and gas industry. The practical significance of understanding this relationship lies in selecting the optimal treatment method based on the specific material, environmental conditions, and desired lifespan of the component or structure.

Further analysis reveals that the type of protection employed can vary greatly. Barrier coatings physically isolate the material, while sacrificial coatings corrode preferentially to protect the underlying metal. Conversion coatings, such as chromate conversion coatings on aluminum (though increasingly restricted due to environmental concerns), chemically alter the surface to make it less susceptible to corrosion. Inhibitive coatings contain chemical compounds that passivate the surface and prevent electrochemical reactions. The choice depends on factors like cost, required performance, and regulatory requirements. For instance, in the marine industry, durable and corrosion-resistant coatings are essential for protecting ship hulls from saltwater corrosion, significantly reducing maintenance costs and extending vessel lifespan.

In summary, corrosion protection is a fundamental consideration within the broader field of surface treatment. Effective implementation requires a thorough understanding of corrosion mechanisms, material properties, and available technologies. While challenges remain in developing environmentally friendly and cost-effective solutions, ongoing research and innovation continue to drive advancements in corrosion-resistant materials and techniques, thereby ensuring the longevity and reliability of infrastructure, equipment, and manufactured goods.

2. Aesthetic Enhancement

Aesthetic enhancement is a core objective of surface treatment, influencing consumer perception and product marketability. The visual and tactile qualities imparted by surface treatments are often key differentiators, especially in competitive markets.

- Color and Gloss Uniformity

Consistent color and gloss are critical for visual appeal. Surface treatments, such as powder coating or specialized paints, provide uniform color distribution and controllable gloss levels. This is evident in automotive manufacturing, where consistent paint finishes across vehicle bodies ensure quality and brand image. Inconsistent finishes can lead to perceived defects and reduced customer satisfaction.

- Surface Texture and Tactility

Texture plays a significant role in the perceived quality of a product. Surface treatments can create textures ranging from smooth and glossy to matte and textured. Examples include the soft-touch coatings on electronic devices, which enhance grip and provide a premium feel. The choice of texture impacts both aesthetics and functionality.

- Decorative Patterns and Graphics

Surface treatments enable the application of decorative patterns and graphics. Techniques like screen printing, pad printing, and laser engraving allow manufacturers to add intricate designs and branding elements. This is common in the packaging industry, where visually appealing labels and decorations attract consumers. Accurate and durable application of these elements is crucial for maintaining brand integrity.

- Hiding Surface Imperfections

Surface treatments can mask or minimize minor surface imperfections on base materials. Coatings can fill small scratches, dents, or porosity, improving the overall appearance of the product. This is valuable in the manufacturing of die-cast components, where surface irregularities are common. Effectively concealing these imperfections enhances the perceived quality and value of the product.

Collectively, color consistency, texture, decorative elements, and imperfection concealment contribute to the overall aesthetic enhancement achieved through surface treatment. The selection of appropriate techniques depends on product requirements, cost considerations, and desired visual impact. Continuously evolving technologies are expanding the range of aesthetic possibilities in manufacturing.

3. Surface Hardness

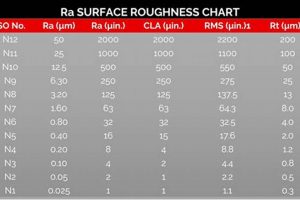

Surface hardness, the resistance of a material to localized plastic deformation caused by indentation or scratching, constitutes a crucial consideration within industrial finishing. It directly influences the durability, wear resistance, and overall performance of components and products. Industrial finishing techniques are often employed specifically to enhance this property, extending service life and minimizing maintenance requirements.

- Case Hardening and Heat Treatment

Processes like carburizing, nitriding, and induction hardening are frequently used to increase the surface hardness of steel components. These methods involve altering the chemical composition or microstructure of the surface layer through controlled heating and cooling cycles. For instance, carburizing introduces carbon into the surface of low-carbon steel, creating a hard, wear-resistant outer layer while maintaining a tough, ductile core. This approach is widely applied in the automotive industry for gears and camshafts, improving their resistance to wear and fatigue under demanding operating conditions.

- Coating Application Techniques

Coatings such as hard chrome plating, titanium nitride (TiN) deposition via physical vapor deposition (PVD), and diamond-like carbon (DLC) coatings are applied to increase surface hardness. Hard chrome plating, for example, provides excellent wear and corrosion resistance, extending the lifespan of hydraulic cylinders and cutting tools. TiN coatings are frequently used on drill bits and milling cutters to improve their cutting performance and reduce tool wear. DLC coatings offer a combination of high hardness, low friction, and chemical inertness, making them suitable for applications like engine components and medical implants.

- Abrasive Blasting and Shot Peening

These surface treatments impart compressive residual stresses into the material surface, increasing hardness and fatigue resistance. Abrasive blasting utilizes high-speed abrasive particles to remove surface contaminants and create a textured surface, improving coating adhesion and increasing surface area. Shot peening involves bombarding the surface with small spherical media, inducing compressive stresses that hinder crack initiation and propagation. This is commonly applied to aircraft components and springs to enhance their fatigue life and prevent premature failure.

- Considerations for Material Selection

The selection of appropriate materials and surface treatment techniques must be carefully considered to achieve desired surface hardness properties. For example, selecting a harder base material may reduce the need for extensive surface treatment. Furthermore, the interaction between the base material and applied coating or treatment must be evaluated to ensure compatibility and prevent issues like delamination or premature wear. Hardness testing methods, such as Vickers, Rockwell, and Knoop hardness tests, are used to verify that the surface treatment has achieved the specified hardness values.

In conclusion, enhancing surface hardness through various industrial finishing techniques is essential for improving the durability, wear resistance, and performance of manufactured components. From heat treatment processes to coating applications and mechanical surface treatments, a range of options exist to tailor surface properties to specific application requirements. Proper material selection, process control, and quality assurance are critical for achieving optimal surface hardness and extending the service life of finished products.

4. Adhesion Quality

Adhesion quality, the measure of the bond strength between a coating or finish and the underlying substrate, is a critical determinant of the overall effectiveness of surface treatment. The consequences of poor adhesion range from cosmetic defects to catastrophic failures, highlighting its importance. A surface treatment’s protective and functional attributes are rendered ineffective if the finish prematurely delaminates, flakes, or blisters. The underlying cause of adhesion failures often stems from inadequate surface preparation, incompatible materials, or improper application techniques. For example, applying a paint coating to a metal surface contaminated with oil will likely result in poor adhesion and subsequent coating failure. In the automotive industry, insufficient pre-treatment of car bodies before painting can lead to peeling and corrosion issues, significantly affecting vehicle lifespan and warranty claims.

The selection of appropriate surface preparation methods, such as abrasive blasting, chemical etching, or solvent cleaning, directly impacts adhesion quality. The method chosen should be tailored to the substrate material and the type of finish being applied. Similarly, the compatibility between the substrate and the coating materials must be carefully considered. Using an incompatible primer or adhesive can weaken the bond and lead to premature failure. Practical applications underscore the need for stringent process controls. For example, in the aerospace industry, specialized coatings are applied to aircraft components to protect against corrosion and erosion. The adhesion of these coatings is essential for ensuring aircraft safety and preventing costly repairs. Rigorous testing methods, such as pull-off testing and cross-cut adhesion testing, are employed to verify that the specified adhesion requirements are met.

In summary, adhesion quality is not merely a desirable attribute but a foundational requirement for successful surface treatment. Maintaining high adhesion requires meticulous attention to surface preparation, material compatibility, and application techniques. While challenges may arise due to material complexity and environmental factors, adherence to established best practices and stringent quality control measures is vital for ensuring the long-term performance and reliability of treated surfaces. The economic implications of adhesion failures are substantial, underscoring the necessity of prioritizing adhesion quality in all aspects of surface finishing processes.

5. Chemical Resistance

Chemical resistance, the ability of a treated surface to withstand degradation or alteration upon exposure to corrosive substances, is a critical performance parameter in many applications of industrial finishing. The selection of appropriate finishing processes and materials hinges on the specific chemical environments anticipated during a product’s service life. Surface treatments that provide inadequate chemical resistance can result in premature failure, loss of functionality, and increased maintenance costs.

- Protective Coatings for Chemical Processing Equipment

Chemical processing facilities employ various surface treatments to protect equipment from highly corrosive substances, such as acids, alkalis, and solvents. Coatings like fluoropolymers (e.g., PTFE, PFA) and epoxy resins are commonly used due to their inertness and resistance to a broad spectrum of chemicals. Inadequate coating selection can lead to equipment corrosion, contamination of process streams, and safety hazards. The performance of these coatings is often evaluated through immersion testing in simulated chemical environments to determine their suitability.

- Surface Passivation for Stainless Steel

Stainless steel relies on a passive chromium oxide layer to provide corrosion resistance. However, this layer can be compromised by surface contamination or aggressive chemical exposure. Passivation treatments, such as nitric acid or citric acid baths, are used to remove free iron and restore the protective passive layer. Improper passivation can result in localized corrosion, known as pitting or crevice corrosion, which can weaken the material and lead to premature failure, especially in applications involving chlorides or reducing acids.

- Anodizing for Aluminum Alloys

Anodizing, an electrochemical process, creates a thick, protective oxide layer on aluminum alloys, enhancing their corrosion resistance and wear resistance. The type of anodizing (e.g., sulfuric acid anodizing, hard anodizing) and the sealing process influence the coating’s chemical resistance. Inadequate sealing of the anodized layer can leave it porous and susceptible to attack by corrosive substances. Anodized aluminum components are frequently used in aerospace, automotive, and architectural applications where resistance to atmospheric corrosion and chemical exposure is essential.

- Powder Coating for Outdoor Applications

Powder coating provides a durable, chemically resistant finish for metal components used in outdoor environments. The thermosetting polymer forms a cross-linked network during curing, resulting in a tough, resistant coating. However, the specific chemistry of the powder coating determines its resistance to particular chemicals. Some powder coatings are more resistant to acids, while others excel in alkaline environments. Proper surface preparation, including cleaning and pretreatment, is critical to ensure adhesion and prevent under-film corrosion. Failure to select an appropriate powder coating for the specific outdoor environment can result in degradation, discoloration, and loss of protective properties.

These facets highlight the diverse ways chemical resistance is addressed through industrial finishing. The selection of the appropriate treatment is dictated by the intended application and the specific chemical environment. The failure to consider these factors can result in costly failures and reduced product lifespan, highlighting the critical importance of chemical resistance in surface treatment strategies.

6. Wear Resistance

Wear resistance, the capacity of a material to withstand surface damage resulting from mechanical action such as abrasion, erosion, adhesion, and fatigue, is a primary consideration in industrial finishing. The application of surface treatments is often motivated by the need to enhance this property, extending the service life of components and reducing the frequency of replacements.

- Hardfacing and Weld Overlays

Hardfacing, a welding process where a wear-resistant alloy is deposited onto a substrate material, is a common technique to improve wear resistance. This is frequently employed in the mining and construction industries, where equipment components such as excavator teeth, crusher jaws, and conveyor screws are subjected to severe abrasive wear. The selection of the hardfacing alloy depends on the specific wear mechanism and operating conditions. Examples include tungsten carbide overlays for extreme abrasion resistance and chromium carbide for resistance to high-temperature wear. The implication is a significant reduction in downtime and replacement costs in harsh environments.

- Thermal Spray Coatings

Thermal spray coatings involve depositing molten or semi-molten materials onto a substrate to create a wear-resistant layer. Techniques such as plasma spraying, high-velocity oxy-fuel (HVOF) spraying, and arc spraying are utilized to apply a variety of materials, including ceramics, metals, and composites. These coatings are used to protect components in aerospace, automotive, and power generation industries. Examples include applying ceramic coatings to turbine blades to resist high-temperature erosion and applying metallic coatings to hydraulic cylinder rods to improve resistance to abrasive wear. Precise control of spraying parameters is essential to achieve desired coating properties and adhesion strength, which directly impacts the coatings wear performance.

- Surface Modification by Ion Implantation

Ion implantation is a process where ions of a specific element are accelerated and implanted into the surface of a material, altering its composition and properties. This technique is used to enhance wear resistance, particularly in applications requiring high precision and low friction. The semiconductor industry utilizes ion implantation to modify the surface of silicon wafers, improving their hardness and wear resistance. In the medical device industry, ion implantation is employed to enhance the wear resistance and biocompatibility of titanium implants. The depth of penetration and concentration of implanted ions are carefully controlled to achieve desired wear properties without significantly affecting the bulk properties of the material.

- Chemical Conversion Coatings with Solid Lubricants

Chemical conversion coatings, such as phosphate coatings or chromate conversion coatings, are often combined with solid lubricants to reduce friction and improve wear resistance. These coatings provide a porous matrix that retains solid lubricants like molybdenum disulfide (MoS2) or graphite, creating a self-lubricating surface. This approach is commonly used in the automotive industry for components such as pistons, bearings, and gears to minimize friction and wear. The effectiveness of this combination depends on the proper selection of both the conversion coating and the solid lubricant to ensure compatibility and optimal wear performance.

These surface treatments, each employing distinct mechanisms and materials, are essential for enhancing wear resistance in a wide array of industrial applications. The successful implementation hinges on understanding the specific wear mechanisms at play and selecting a finishing process that effectively mitigates those mechanisms. The continuous development of new materials and techniques promises further advancements in the field of industrial finishing, enabling the creation of more durable and reliable products.

7. Environmental Compliance

Environmental compliance is an increasingly critical aspect of industrial finishing. Regulatory frameworks worldwide are placing greater emphasis on minimizing the environmental impact of manufacturing processes, demanding that companies adopt more sustainable practices. This requires a careful evaluation and modification of finishing techniques to reduce emissions, waste generation, and the use of hazardous materials.

- Reduction of Volatile Organic Compounds (VOCs)

Many traditional finishing processes, such as solvent-based painting, release VOCs into the atmosphere, contributing to air pollution and posing health risks. Environmental regulations often mandate the reduction or elimination of VOC emissions. This has driven the adoption of alternative finishing methods, such as water-based coatings, powder coatings, and UV-curable coatings, which release significantly fewer VOCs. For example, the transition from solvent-based to water-based paints in the automotive industry has substantially reduced VOC emissions. Failure to comply with VOC emission limits can result in fines, production shutdowns, and reputational damage.

- Management of Hazardous Waste

Industrial finishing processes frequently generate hazardous waste, including spent solvents, waste coatings, and contaminated rinse water. Proper management of this waste is essential to prevent environmental contamination and ensure compliance with hazardous waste regulations. This involves implementing waste minimization strategies, such as source reduction, recycling, and proper disposal methods. For instance, electroplating operations generate wastewater containing heavy metals, which must be treated to remove the contaminants before discharge. Failure to comply with hazardous waste regulations can lead to substantial penalties and legal liabilities.

- Restrictions on the Use of Certain Chemicals

Many chemicals used in industrial finishing processes have been identified as hazardous to human health and the environment. Regulations such as REACH (Registration, Evaluation, Authorisation and Restriction of Chemicals) in Europe restrict or prohibit the use of certain chemicals, prompting companies to seek safer alternatives. Examples include the phase-out of hexavalent chromium in chromating processes and the substitution of perfluorinated compounds (PFCs) in surface treatment applications. The transition to safer chemicals can require significant investment in research and development, process modifications, and employee training. However, compliance with chemical restrictions is essential to protect worker health and the environment.

- Energy Efficiency and Resource Conservation

Industrial finishing processes can be energy-intensive, requiring significant amounts of electricity, natural gas, and water. Efforts to improve energy efficiency and conserve resources can reduce environmental impact and lower operating costs. This includes optimizing process parameters, implementing energy-efficient equipment, and recycling water. For instance, the use of infrared curing systems for coatings can reduce energy consumption compared to conventional ovens. Similarly, closed-loop water systems can minimize water usage and wastewater discharge. Adoption of sustainable practices demonstrates corporate social responsibility and can provide a competitive advantage.

These interwoven elements underscore the necessity for industrial finishing operations to integrate environmental considerations into every stage of their processes. Compliance with environmental regulations is not merely a legal obligation but an ethical imperative. By embracing sustainable practices and continuously seeking innovative solutions, the finishing industry can minimize its environmental footprint and contribute to a more sustainable future.

Frequently Asked Questions About Industrial Finishing

The following questions address common inquiries and misconceptions concerning methods, applications, and best practices.

Question 1: What distinguishes industrial finishing from other types of finishing processes?

Industrial finishing is characterized by its focus on large-scale manufacturing, high-volume production, and rigorous performance requirements. Unlike artistic or craft-based finishing, processes are engineered for consistency, durability, and often involve specialized equipment and controls to meet stringent industry standards. The emphasis is on functionality, protection, and repeatable quality across numerous components.

Question 2: How is the appropriate surface treatment method selected for a given application?

Selection depends on several factors, including the substrate material, the intended service environment, the desired performance characteristics (e.g., corrosion resistance, wear resistance, aesthetic appeal), and regulatory requirements. A comprehensive evaluation involves assessing material compatibility, environmental conditions, performance criteria, cost considerations, and compliance with applicable standards. Consulting with materials engineers or finishing specialists is often recommended.

Question 3: What are the key considerations for ensuring optimal adhesion of coatings?

Optimal adhesion requires meticulous surface preparation, including cleaning to remove contaminants, creating a suitable surface profile (e.g., through abrasive blasting), and applying appropriate pretreatments (e.g., primers or conversion coatings). Material compatibility between the substrate and the coating is also essential. Furthermore, strict control of application parameters, such as temperature, humidity, and coating thickness, is crucial for achieving a strong and durable bond.

Question 4: What are the primary environmental concerns associated with industrial finishing processes?

Concerns include emissions of volatile organic compounds (VOCs), generation of hazardous waste (e.g., spent solvents, heavy metals), and the use of toxic chemicals (e.g., hexavalent chromium). Regulations mandate the reduction or elimination of these environmental hazards through the adoption of cleaner technologies, waste minimization strategies, and the substitution of safer materials. Compliance with environmental standards is critical for sustainable manufacturing.

Question 5: How is quality control maintained in industrial finishing operations?

Quality control involves a combination of process monitoring, in-process inspections, and final product testing. Process monitoring includes tracking parameters such as temperature, pressure, and coating thickness. Inspections verify surface cleanliness, coating uniformity, and absence of defects. Final product testing assesses performance characteristics such as adhesion, corrosion resistance, and wear resistance using standardized methods. Statistical process control (SPC) is often employed to identify and address process variations.

Question 6: What are some emerging trends in industrial finishing?

Emerging trends include the development of more environmentally friendly coatings, such as bio-based and waterborne formulations, the increased use of nanotechnology to enhance coating properties, the application of advanced surface modification techniques like plasma treatment, and the integration of automation and robotics to improve process efficiency and consistency. Furthermore, there is a growing emphasis on sustainable finishing practices and circular economy principles.

Effective processes are fundamental to producing high-quality, durable goods across diverse industries. A strong grasp of the techniques involved ensures both performance and regulatory compliance.

The subsequent sections will explore case studies and examine emerging technologies that further optimize practices.

Industrial Finishing

This exploration of industrial finishing has highlighted its significance in enhancing the properties, performance, and longevity of manufactured goods. From corrosion protection and aesthetic improvements to enhanced surface hardness and chemical resistance, surface treatments play a pivotal role across numerous industries. The imperative to comply with increasingly stringent environmental regulations further underscores the importance of adopting sustainable finishing practices.

Continued innovation in materials science, process optimization, and environmental stewardship will shape the future of industrial finishing. Further research and development are essential to address evolving challenges and unlock new possibilities for enhancing product performance and sustainability. A commitment to best practices is required for all stakeholders.