A surface treatment tailored to specific requirements allows for unique aesthetic and performance characteristics. This specialized process often involves selecting particular materials, textures, and colors that deviate from standard offerings. For instance, a metal component might undergo a distinct coating procedure to achieve enhanced corrosion resistance and a particular visual appeal not readily available in pre-fabricated options. This personalization extends beyond mere decoration, impacting the longevity and functionality of the item.

The value of individually tailored surface treatments lies in their capacity to meet demanding specifications and design visions. Historically, such specialized processes were employed to protect critical infrastructure and create enduring works of art. Modern applications span diverse industries, including automotive, aerospace, and consumer goods, reflecting a growing appreciation for solutions that precisely match the intended use case. The benefits include improved durability, enhanced aesthetics, and the ability to differentiate products in competitive markets, leading to increased perceived value and customer satisfaction.

Having established the foundation of tailored surface applications, the following sections will delve into the specific techniques, materials, and considerations involved in achieving various desired outcomes. Subsequent discussions will cover topics such as material selection, application methods, quality control measures, and emerging trends in this dynamic field.

Achieving Optimal Results with a Tailored Surface Application

The following guidelines are designed to enhance the execution and outcome of any project requiring a individualized surface solution. Careful consideration of these points will contribute to a successful result that aligns with the intended purpose and aesthetic requirements.

Tip 1: Conduct Thorough Material Compatibility Testing. Before committing to a full-scale application, rigorously test the chosen coating or treatment on representative samples of the substrate material. This ensures adhesion, prevents adverse reactions, and confirms that the finish will perform as expected under anticipated environmental conditions.

Tip 2: Precisely Define Performance Requirements. Clearly articulate the specific performance criteria the tailored surface must meet. This includes factors such as resistance to abrasion, corrosion, UV exposure, and chemical attack. This clarity guides the selection of appropriate materials and application methods.

Tip 3: Establish Rigorous Quality Control Procedures. Implement stringent quality control measures throughout the process. This includes inspections at each stage, from surface preparation to final application, to identify and correct any defects promptly.

Tip 4: Optimize Surface Preparation Techniques. The quality of the substrate surface is critical to the success of the finished product. Proper preparation, such as cleaning, etching, or priming, ensures optimal adhesion and longevity of the tailored surface.

Tip 5: Calibrate Application Equipment Meticulously. Ensure that all application equipment, such as spray guns or coating machines, is properly calibrated and maintained. This guarantees consistent and uniform coverage, minimizing variations in thickness and appearance.

Tip 6: Control Environmental Conditions During Application. Carefully manage environmental factors such as temperature, humidity, and air quality during the application process. These conditions can significantly impact the curing, adhesion, and overall quality of the finished surface.

Tip 7: Document the Entire Process Comprehensively. Maintain detailed records of all materials used, application parameters, and quality control checks. This documentation provides valuable information for future reference, troubleshooting, and potential improvements.

These tips emphasize the importance of meticulous planning, execution, and monitoring to ensure that a tailored surface application meets the required performance and aesthetic standards, ultimately contributing to the product’s overall success and longevity.

The succeeding sections will explore further the practical aspects of applying specialized finishes, delving into specific techniques and troubleshooting common challenges.

1. Material Selection

Material selection serves as the cornerstone of achieving any individualized surface application. The inherent properties of the chosen material fundamentally dictate the range of possible aesthetic and functional outcomes. Careful consideration of these properties is essential for realizing a successful and durable result.

- Substrate Compatibility

The substrate, or base material, must be compatible with the intended coating or treatment. Incompatibility can lead to poor adhesion, premature failure, and compromised performance. For example, applying a water-based coating to a substrate prone to moisture absorption may result in blistering and delamination. Proper selection considers factors such as surface energy, porosity, and chemical reactivity.

- Coating Performance Characteristics

The coating material must possess the necessary performance characteristics to meet the demands of the intended application. This includes factors such as resistance to abrasion, corrosion, UV exposure, and chemical attack. An automotive finish, for instance, requires high levels of scratch resistance and UV protection to withstand the rigors of daily use and environmental exposure. Coatings are engineered with specific additives and formulations to achieve these desired properties.

- Aesthetic Properties

The aesthetic properties of the coating material directly contribute to the overall appearance of the individualized surface. This encompasses attributes such as color, gloss, texture, and transparency. A high-end consumer product, for example, may require a specific color match and a flawless, high-gloss finish to convey a sense of quality and luxury. Pigments, dyes, and other additives are used to achieve the desired visual effects.

- Application Method Suitability

The selected material must be compatible with the chosen application method. Some coatings are best suited for spraying, while others are better applied by dipping, brushing, or rolling. For example, a high-viscosity coating may require specialized spraying equipment to ensure proper atomization and uniform coverage. Compatibility between material and application method is crucial for achieving a consistent and defect-free finish.

The interplay between substrate compatibility, coating performance, aesthetic properties, and application method suitability highlights the critical importance of informed material selection. By carefully considering these factors, it is possible to achieve personalized surface applications that not only meet functional requirements but also enhance the aesthetic appeal and overall value of the finished product.

2. Surface Preparation

Surface preparation is a critical determinant in the success of any individualized surface application. Its efficacy directly impacts adhesion, durability, and the overall aesthetic quality of the final result. Inadequate surface preparation invariably leads to premature failure and compromised performance, regardless of the quality of the coating material itself.

- Cleaning and Degreasing

The removal of contaminants such as oil, grease, dirt, and fingerprints is paramount. These substances interfere with the proper bonding of the coating to the substrate. Methods employed include solvent wiping, alkaline cleaning, and vapor degreasing. For instance, in automotive refinishing, thorough degreasing ensures the paint adheres uniformly and prevents fish-eye defects. Insufficient cleaning results in poor adhesion and a compromised lifespan.

- Abrasive Blasting

Abrasive blasting techniques, such as sandblasting, bead blasting, and media blasting, are used to remove existing coatings, corrosion, and surface imperfections. These methods create a textured surface that enhances mechanical adhesion. In the context of architectural metalwork, abrasive blasting prepares the surface for a powder coat, ensuring a durable and aesthetically pleasing finish that withstands environmental exposure. Inadequate abrasion negatively affects coating grip and increases susceptibility to corrosion.

- Chemical Etching

Chemical etching involves the use of acids or alkaline solutions to modify the substrate surface at a microscopic level. This process creates a profile that promotes mechanical interlocking between the substrate and the coating. An example includes the etching of aluminum prior to anodizing, which enhances the oxide layer’s adhesion and corrosion resistance. Substandard etching inhibits proper interlocking, diminishing the finish’s protective capabilities.

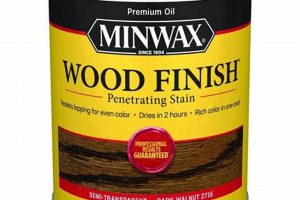

- Priming and Sealing

Primers are applied to the prepared surface to provide a uniform base for subsequent coatings, improve adhesion, and inhibit corrosion. Sealers are used to prevent moisture ingress and protect porous substrates. In the context of wood finishing, a primer seals the wood pores, preventing uneven absorption of the topcoat and ensuring a consistent color and sheen. Omitting the primer results in uneven color application and an unsatisfactory end appearance.

The facets of surface preparation described above underscore its indispensable role in achieving desired individualized surface outcomes. Proper attention to cleaning, abrasion, etching, and priming ensures that the applied coating performs optimally, providing long-lasting protection and enhancing the aesthetic appeal of the finished product. Neglecting these steps inevitably compromises the integrity and longevity of the tailored surface.

3. Application Technique

The application technique employed exerts a direct and significant influence on the ultimate characteristics of a individualized surface. The chosen method determines the uniformity, thickness, and texture of the coating, directly impacting its aesthetic appeal and protective capabilities. Variations in technique lead to discernible differences in the finish’s visual presentation and its ability to withstand environmental stressors. For example, a sprayed coating applied with inconsistent gun speed and distance may exhibit runs, sags, or orange peel, compromising both its aesthetic and functional properties. In contrast, a carefully applied, uniform coating provides superior protection and visual appeal.

The selection of application technique is also dictated by the properties of the coating material and the geometry of the substrate. High-viscosity coatings, for instance, may require specialized spray equipment to ensure proper atomization and even distribution. Intricate geometries may necessitate techniques such as electrostatic spraying, which utilizes an electrical charge to attract the coating to the substrate, ensuring complete coverage in recessed areas. Consider the application of powder coating to complex metal parts: proper electrostatic application ensures even coverage of edges and corners, preventing corrosion and enhancing durability. Therefore, each method provides its own set of advantages and is chosen to suit specific material and design needs.

In summary, the application technique is an integral element in achieving a desired personalized surface, representing a pivotal factor in determining its final appearance and performance. The appropriateness and precision of the technique directly influence the coating’s uniformity, adherence, and protective qualities. A thorough understanding of various application methods, coupled with meticulous execution, is essential for creating enduring and visually appealing personalized surfaces. The synergy between material selection, surface preparation, and application technique ultimately governs the success of any project aiming for an individualized surface.

4. Performance Requirements

The link between defined performance criteria and a tailored surface treatment is a direct causal relationship. Performance requirements dictate the selection and implementation of specific surface applications. These requirements are not arbitrary; they stem from the intended use environment and the desired longevity of the component. For example, a marine-grade application mandates corrosion resistance, leading to the selection of a specialized coating process like hot-dip galvanization or the application of epoxy coatings. Without clearly defined performance targets, the selection of an appropriate surface treatment becomes arbitrary, increasing the risk of premature failure and compromising the integrity of the underlying material.

The importance of performance specifications extends beyond mere material protection. In the aerospace industry, specialized coatings are applied to turbine blades to withstand extreme temperatures and prevent oxidation. These coatings, often involving ceramic materials and complex deposition techniques, are selected based on precise thermal and mechanical stress analyses. Similarly, in the medical device sector, biocompatible coatings are essential to prevent adverse reactions within the human body. These examples illustrate how the understanding and precise definition of required performance characteristics directly influence the choice and execution of the finishing process. Deviation from specified processes, or selection of inadequate materials, renders the finished product unsafe or ineffective.

In conclusion, performance requirements are not merely an adjunct to a tailored surface treatment but rather its foundational directive. Accurate assessment and articulation of these requirements are essential for selecting appropriate materials, processes, and quality control measures. Failure to adequately define performance objectives undermines the entire finishing process, resulting in substandard outcomes and potential safety or functional risks. Consequently, a robust understanding of the operational environment and required functionality is paramount to achieving a successful and durable individualized surface application.

5. Durability Enhancement

Durability enhancement, when considered in conjunction with individualized surface applications, becomes a pivotal determinant of long-term performance and cost-effectiveness. The selection and execution of specialized finishes directly influence a product’s resistance to wear, corrosion, and environmental degradation, thereby extending its operational lifespan. This proactive approach to longevity contributes to reduced maintenance, fewer replacements, and an overall improvement in lifecycle costs.

- Corrosion Resistance

Many individualized surface treatments are engineered to provide enhanced protection against corrosion, a primary cause of material degradation. Coatings such as specialized epoxies, powder coats, or galvanization processes create a barrier between the substrate and corrosive elements like moisture, salt, and chemicals. In offshore oil and gas platforms, for example, tailored corrosion-resistant finishes are essential to withstand the harsh marine environment, preventing structural failure and ensuring operational safety. Proper selection and application of these coatings significantly extends the lifespan of critical infrastructure.

- Abrasion Resistance

Surfaces subjected to frequent physical contact require specialized treatments to resist abrasion and wear. Hard coatings, such as ceramic or diamond-like carbon (DLC) films, are applied to components to enhance their resistance to scratching, erosion, and general wear and tear. In the manufacturing sector, tooling and machine components often receive abrasion-resistant individualized finishes to maintain dimensional accuracy and extend their service life. Without these specialized treatments, premature wear would necessitate frequent replacements, leading to increased downtime and production costs.

- UV Protection

Prolonged exposure to ultraviolet (UV) radiation can cause degradation of many materials, particularly polymers and organic coatings. Specialized finishes incorporating UV absorbers or stabilizers mitigate the damaging effects of sunlight, preventing discoloration, cracking, and loss of mechanical properties. In the automotive industry, exterior paint finishes are formulated with UV protection to maintain their appearance and structural integrity over time. The presence of effective UV protection ensures that the individualized surface maintains its aesthetic appeal and functional performance throughout its service life.

- Chemical Resistance

Components exposed to harsh chemical environments, such as those found in chemical processing plants, require specialized surface treatments to resist degradation. Coatings such as fluoropolymers or specialized epoxies provide a barrier against chemical attack, preventing corrosion, swelling, and dissolution. In the pharmaceutical industry, equipment used in the production of drugs often receives chemically resistant individualized finishes to ensure product purity and prevent contamination. The selection of appropriate chemical-resistant coatings is critical to maintaining operational safety and product quality.

These distinct methods, tailored to counter specific degradation mechanisms, collectively underscore the pivotal role of durability enhancement in the context of individualized surface applications. By carefully selecting and implementing specialized finishes that address anticipated environmental and operational stressors, it is possible to significantly extend the lifespan of components, reduce maintenance costs, and improve overall performance. This proactive approach to durability ensures that the individualized surface not only meets immediate aesthetic and functional requirements but also provides long-term value and reliability.

Frequently Asked Questions Regarding Individualized Surface Applications

This section addresses common inquiries concerning specialized surface treatments, aiming to clarify misconceptions and provide concise, informative answers.

Question 1: What distinguishes an individualized surface application from a standard coating?

An individualized surface application is a tailored treatment designed to meet specific performance or aesthetic requirements, whereas a standard coating typically serves general-purpose protective or decorative functions. The former often involves customized formulations and application techniques to achieve precise outcomes, while the latter relies on standardized processes.

Question 2: What factors influence the cost of a specialized surface application?

The cost of a tailored surface treatment is influenced by factors such as material selection, surface preparation requirements, application complexity, volume of material, and the level of quality control necessary. More demanding performance criteria and intricate application procedures generally result in higher costs.

Question 3: How is the appropriate surface treatment selected for a given application?

The selection process involves a thorough assessment of the substrate material, intended use environment, performance requirements (e.g., corrosion resistance, abrasion resistance), and aesthetic considerations. Material compatibility testing and performance modeling are often employed to optimize the selection process.

Question 4: What quality control measures are employed to ensure the integrity of an individualized surface?

Quality control measures typically include visual inspections, adhesion testing, thickness measurements, and performance testing under simulated environmental conditions. Non-destructive testing methods, such as ultrasonic inspection, may also be used to detect subsurface defects.

Question 5: What are the limitations of specialized surface treatments?

Limitations may include cost constraints, environmental regulations governing material usage, geometric constraints that limit application methods, and the potential for incompatibility between the coating and the substrate. Certain treatments may also exhibit limitations in terms of temperature resistance or chemical compatibility.

Question 6: How does one ensure the long-term durability of a personalized surface?

Long-term durability is ensured through proper material selection, meticulous surface preparation, precise application techniques, and the implementation of a regular maintenance schedule. Periodic inspections and recoating, as needed, are essential to preserving the integrity of the tailored surface.

These answers underscore the importance of informed decision-making when considering specialized surface treatments. Careful consideration of these factors will contribute to optimal performance and longevity.

The subsequent section will explore case studies demonstrating the application of tailored surfaces in various industries.

Custom Finish

This exploration has demonstrated that “custom finish” represents more than a superficial enhancement; it is a critical element in optimizing performance, extending lifespan, and meeting specific functional requirements. The judicious selection of materials, rigorous surface preparation, precise application techniques, and clearly defined performance criteria collectively determine the ultimate success of any specialized surface application. Neglecting any of these components compromises the integrity and longevity of the resulting finish.

The information presented serves as a foundational resource for professionals and decision-makers involved in specifying or implementing tailored surface treatments. A thorough understanding of these principles facilitates informed decision-making, leading to more durable, reliable, and aesthetically appropriate outcomes. Future advancements in materials science and application technologies will continue to expand the possibilities of surface engineering, further enhancing the value and impact of custom finishes across diverse industries.

![Fix: Washer Not Finishing Cycle? [Easy Solutions] Best Final Touch: Elevate Your Projects with Professional Finishing Fix: Washer Not Finishing Cycle? [Easy Solutions] | Best Final Touch: Elevate Your Projects with Professional Finishing](https://bestfinaltouch.com/wp-content/uploads/2026/02/th-346-300x200.jpg)