A surface coating, typically composed of natural or synthetic waxes, designed to enhance and protect wooden surfaces. Applied as a final layer, it provides a lustrous sheen and a tactile quality to previously finished wood items. An example includes applying beeswax to a polished table to increase its shine and resistance to minor scratches.

The application offers several advantages. It augments the aesthetic appeal of wood, highlighting the grain and adding depth to the color. Functionally, it provides a degree of protection against moisture, fingerprints, and everyday wear. Historically, these coatings have been used for centuries to preserve and beautify wooden furniture and architectural elements, reflecting a tradition of craftsmanship and care.

The subsequent sections will examine the different types available, application techniques, considerations for selecting the appropriate product, and best practices for maintaining a waxed wood surface.

Application Best Practices

Achieving optimal results requires careful attention to detail and adherence to established methods. The following guidelines offer insight into maximizing the effectiveness of the process.

Tip 1: Preparation is Paramount: Prior to application, ensure the wood surface is clean, dry, and free of any existing finishes or contaminants. Sanding with fine-grit sandpaper may be necessary to create a smooth and receptive substrate.

Tip 2: Apply Thin, Even Coats: Avoid applying excessive amounts. Multiple thin coats are preferable to a single thick coat, as this promotes even coverage and reduces the risk of clouding or streaking. Allow each coat to dry completely before applying the next.

Tip 3: Use Appropriate Application Tools: Employ a soft cloth, brush, or applicator specifically designed for the task. Lint-free cloths are crucial to prevent unwanted residue from being embedded within the finish.

Tip 4: Buff to Enhance Sheen: After the final coat has dried, buff the surface with a clean, soft cloth to achieve the desired level of sheen. The intensity of the buffing will influence the final gloss level.

Tip 5: Consider Ambient Conditions: Temperature and humidity can impact drying times and the overall quality. Avoid application in extremely humid or cold environments.

Tip 6: Perform a Test Application: On an inconspicuous area or a scrap piece of wood, test the application technique and the compatibility of the product with the underlying finish.

Tip 7: Allow Adequate Drying Time: Rushing the drying process can compromise the integrity and appearance of the finish. Adhere to the manufacturer’s recommended drying times.

Following these guidelines contributes to a durable and aesthetically pleasing result, preserving and enhancing the natural beauty of the wood.

The subsequent section will delve into common issues encountered during and after application and how to address them effectively.

1. Protection

The fundamental role of a wood surface coating centers on its protective capabilities. This type of coating provides a barrier against environmental factors that can degrade wood, including moisture, ultraviolet radiation, and physical abrasion. The coating acts as a sacrificial layer, absorbing damage that would otherwise affect the underlying wood structure. For example, a waxed dining table withstands minor spills and scratches, preventing stains and preserving the wood’s integrity.

Furthermore, this coating prevents the wood from drying out excessively, which can lead to cracking and warping. By sealing the wood’s surface, it regulates moisture exchange, maintaining a stable internal environment. The selection of a specific product should be based on the degree of protection required, considering factors such as the wood type, its intended use, and the environmental conditions to which it will be exposed. Proper application and maintenance are vital to ensuring the long-term effectiveness of the protective barrier.

In summary, the protective aspect of a surface coating is paramount, influencing its selection, application, and maintenance. Understanding the mechanisms by which protection is achieved enables informed decision-making, resulting in enhanced durability and longevity of wooden objects. The challenge lies in balancing the need for robust protection with aesthetic considerations, achieving a finish that is both functional and visually appealing.

2. Appearance

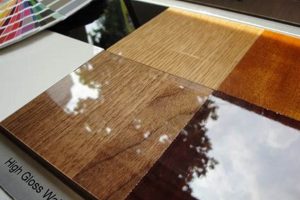

The aesthetic properties imparted to wood by a final coating are a significant consideration in its selection and application. The coating’s primary influence on appearance stems from its ability to enhance the wood’s natural grain, depth, and color. Specific formulations can either amplify these characteristics or impart a subtle sheen, altering the perception of the underlying wood. The effect is not merely cosmetic; it contributes to the overall perceived value and quality of the finished product. For instance, applying a transparent coating to a walnut table intensifies the richness of its color and highlights the intricate grain patterns, elevating its visual appeal and market value.

Different application techniques and product types yield varying levels of gloss and clarity, directly influencing the final appearance. Matte coatings minimize reflection, emphasizing the wood’s texture and natural color, while gloss finishes create a reflective surface, enhancing depth and luster. This versatility allows for customization to suit specific aesthetic preferences and design requirements. Furthermore, tinted coatings can be used to alter the wood’s color, achieving a desired aesthetic that complements surrounding decor. The selection process should, therefore, consider the desired visual effect in relation to the inherent characteristics of the wood itself.

In summary, the appearance achieved through the application of a surface coating is a critical factor driving its use. By manipulating the gloss, clarity, and color, the coating transforms the raw material into a refined and visually appealing product. Understanding the nuances of these effects enables informed choices, ensuring that the final appearance aligns with the intended design and aesthetic goals. The challenge lies in balancing the desire for enhanced appearance with the need for durable protection, selecting a product that satisfies both requirements.

3. Application

The effectiveness of any wood surface treatment is inextricably linked to the methodology employed during its application. Poor technique undermines the inherent protective and aesthetic properties of even the highest quality product. Uneven coverage, insufficient preparation, or improper drying conditions can lead to a compromised finish, characterized by blemishes, inadequate protection, and a diminished lifespan. The process is not merely a superficial covering; it is an integral component that dictates the ultimate success of the wood preservation effort. For example, applying a coat of finish without proper surface preparation (cleaning, sanding) often results in poor adhesion and premature failure of the protective layer.

Specific application techniques vary depending on the type of product, the wood species, and the desired outcome. Brushing, wiping, and spraying are common methods, each with its advantages and disadvantages. The selection of the appropriate technique depends on factors such as the viscosity of the product, the complexity of the surface, and the level of control required. Moreover, environmental conditions, such as temperature and humidity, significantly influence the drying and curing process, demanding careful consideration and adjustments to the application process. The failure to address these factors results in issues ranging from slow drying times and uneven sheens to the formation of bubbles and cracks.

In conclusion, the application process is a critical determinant of the success. It influences the degree of protection, the final appearance, and the longevity of the treatment. A thorough understanding of the applicable techniques, product characteristics, and environmental considerations is essential for achieving optimal results and maximizing the benefits of wood preservation efforts. The challenge lies in mastering the nuances of application and adapting the process to the specific requirements of each project, ensuring a durable and aesthetically pleasing result.

4. Durability

Durability represents a key performance attribute directly influenced by the selection and application of a final coating on wood. The longevity and resistance to wear of the treated surface are critical factors determining the overall value and suitability of the coating for its intended purpose.

- Resistance to Abrasion

A coating’s ability to withstand physical contact and friction directly impacts its durability. A finish that easily scratches or wears away provides inadequate long-term protection and compromises the wood’s appearance. For example, a high-traffic floor requires a coating formulated to resist abrasion from foot traffic and furniture movement, ensuring that the underlying wood remains protected and visually appealing over time.

- Moisture Resistance

A durable finish effectively repels moisture, preventing water damage, swelling, and warping of the wood. The effectiveness of this barrier directly correlates with the coating’s composition and its ability to form a continuous and impermeable layer. Consider exterior wood furniture; a robust, moisture-resistant finish protects against rain and humidity, prolonging its lifespan and preventing structural deterioration.

- Chemical Resistance

Exposure to household chemicals, cleaners, and solvents can degrade certain coatings, leading to discoloration, softening, or complete failure. A durable finish exhibits resistance to a range of common chemicals, maintaining its integrity and protective qualities even under demanding conditions. For instance, a kitchen countertop benefits from a coating resistant to spills of acidic foods, cleaning agents, and other common kitchen chemicals.

- UV Protection

Ultraviolet (UV) radiation can cause fading, discoloration, and degradation of wood finishes, especially in outdoor applications. A durable finish incorporates UV inhibitors that block or absorb harmful UV rays, preventing premature aging and maintaining the coating’s aesthetic properties over time. Outdoor furniture and decking benefit significantly from UV-resistant finishes, preventing color fading and structural weakening due to prolonged sun exposure.

These interconnected facets highlight the critical role of durability in evaluating and selecting a wood surface treatment. The ability to resist abrasion, moisture, chemicals, and UV radiation directly influences the coating’s longevity and effectiveness in protecting and preserving the underlying wood. Proper selection based on the intended use and environment ensures that the coating delivers lasting protection and aesthetic appeal, maximizing the value and lifespan of the wood it protects.

5. Composition

The composition of a wood surface coating fundamentally dictates its performance characteristics, influencing its protective qualities, aesthetic properties, and long-term durability. A nuanced understanding of the constituent elements and their interactions is essential for selecting an appropriate product and achieving optimal results.

- Type of Wax

The primary wax component, whether natural (beeswax, carnauba) or synthetic (microcrystalline, polyethylene), defines the coating’s hardness, melting point, and resistance to solvents. Beeswax imparts a soft, workable finish, ideal for furniture, while carnauba provides a harder, more durable surface suitable for floors. The selection of wax type dictates the final product’s suitability for various applications.

- Solvents and Carriers

These volatile components, such as mineral spirits or citrus oils, control the viscosity and application characteristics of the product. They facilitate even distribution of the wax and contribute to the drying time. The type and concentration of solvents can also affect the finish’s odor and environmental impact. A coating with low-VOC (volatile organic compounds) solvents minimizes health risks and environmental concerns.

- Additives and Modifiers

These ingredients, including hardeners, UV absorbers, and colorants, enhance specific performance attributes. Hardeners increase the coating’s abrasion resistance, UV absorbers protect against fading from sunlight, and colorants impart a desired hue. The careful selection of additives allows for customization of the coating’s properties to meet specific requirements. Example: addition of tung oil to improve water resistance.

- Resins and Binders

Resins and binders act as agents that keep a coating adhered to the wood surface. Many different types of resins are available such as Alkyd, Acrylic or Oil Based resin, depending on desired coating look, protection and purpose. Each resin type will provide drastically different results and require specific methods of application. Example: Acrylic resins offer UV resistance but poor protection against water.

The interplay of these components within a wood surface coating’s composition determines its overall performance and suitability for various applications. A carefully balanced formulation, taking into account the desired protective qualities, aesthetic properties, and environmental impact, is essential for achieving a durable, attractive, and long-lasting finish. Selecting a product based on a thorough understanding of its composition ensures that it meets the specific needs of the project and provides optimal results.

6. Maintenance

The longevity and sustained aesthetic appeal of wood surfaces treated with a final coating are directly contingent upon diligent maintenance practices. A surface coating, while providing initial protection, is not impervious to wear and environmental factors. Its effectiveness diminishes over time without appropriate upkeep, leading to degradation of the finish and potential damage to the underlying wood. Regular cleaning, periodic reapplication of the coating, and prompt attention to minor damage are crucial for preserving the integrity and appearance of the treated surface. For example, a waxed wooden floor requires regular sweeping and occasional damp mopping to remove dirt and debris that can abrade the finish. Without these measures, the coating will gradually wear away, exposing the wood to moisture and scratches.

The specific maintenance requirements vary depending on the type of coating applied and the environmental conditions to which the wood is exposed. Surfaces subject to high traffic or frequent contact with moisture require more frequent cleaning and reapplication of the coating. Certain cleaning agents can damage or strip the finish, necessitating the use of pH-neutral or specifically formulated cleaning products. A kitchen countertop, for instance, needs regular cleaning with a mild, non-abrasive cleaner to remove food residue and prevent staining. Furthermore, any scratches, water rings, or other imperfections should be addressed promptly to prevent further damage. Minor scratches can often be buffed out with a soft cloth and a small amount of wax, while more significant damage may require professional repair.

In summary, maintenance is an indispensable component of preserving the effectiveness and aesthetic appeal of wood surfaces. By implementing a consistent maintenance regimen, the lifespan of the coating is extended, the wood is protected from damage, and the overall value of the treated item is sustained. Neglecting maintenance practices inevitably leads to deterioration of the finish, requiring costly repairs or complete refinishing. Adherence to recommended maintenance procedures ensures that the investment in coating the wood is protected and that the wood remains in optimal condition for years to come.

Frequently Asked Questions About Wood Surface Coatings

The following section addresses common inquiries regarding the application, properties, and maintenance of protective coatings designed for wooden surfaces.

Question 1: What constitutes the primary function of a surface treatment applied to wood?

The principal objective is to provide a protective barrier against environmental factors, including moisture, abrasion, and ultraviolet radiation, thereby extending the lifespan and preserving the aesthetic qualities of the wood.

Question 2: How does the composition of a wood surface coating affect its performance?

The specific ingredients, such as the type of wax, solvents, and additives, determine the coating’s hardness, drying time, resistance to solvents, and overall durability. The selection of components is critical for achieving desired results.

Question 3: What factors should be considered when selecting a wood surface coating?

The intended use of the wood, the environmental conditions to which it will be exposed, the desired aesthetic properties, and the level of protection required should all be considered when making a selection.

Question 4: What are the essential steps involved in properly applying a wood surface coating?

Surface preparation, application of thin, even coats, proper drying time, and buffing to achieve the desired sheen are all critical steps in the application process.

Question 5: How can the durability of a wood surface coating be maximized?

Proper application techniques, selection of a durable coating material, and consistent maintenance practices, including regular cleaning and reapplication, are essential for maximizing durability.

Question 6: What are common maintenance practices for wood surfaces treated with a protective coating?

Regular cleaning with appropriate cleaning agents, prompt attention to scratches or blemishes, and periodic reapplication of the coating are all important maintenance practices.

In summary, understanding the function, composition, selection, application, and maintenance of wood surface coatings is crucial for achieving optimal results and ensuring the longevity and beauty of wooden surfaces.

The subsequent section will explore specific types of wood surface coatings and their respective applications.

Conclusion

This exploration has elucidated the multifaceted nature of finish wax for wood, underscoring its significance in both protecting and enhancing wooden surfaces. The composition, application, and maintenance of finish wax for wood each contribute to the overall performance and longevity of the treated material. Understanding these elements is paramount for achieving optimal results.

Effective implementation of finish wax for wood techniques demands informed decision-making and meticulous execution. The informed application of these principles remains crucial for preserving and appreciating the inherent beauty and durability of wood for generations to come. Further research and development in wood surface treatments will inevitably yield even more effective methods for protecting and enhancing this valuable resource.