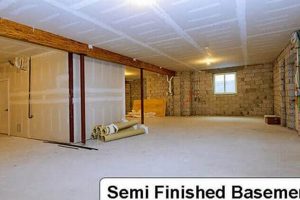

The process of completing the installation and aesthetic integration of openings below ground level involves several key steps. This often includes framing, insulation, drywalling, and trim work to transform a raw opening into a functional and visually appealing element of the finished space.

Properly addressing these structural components enhances energy efficiency by minimizing drafts and heat loss. This also increases the livable square footage of a dwelling, improves its overall market value, and creates a more comfortable and secure environment within the home. Historically, these lower-level openings were often left unfinished, leading to inefficiencies and detracting from the perceived value of the space.

Subsequent sections will detail specific methods, material choices, and best practices for achieving a professional and long-lasting result in subterranean living areas. The discussions will cover aspects of framing, insulation, moisture control, and interior finishing techniques.

Essential Considerations for Window Completion Below Grade

The following are crucial considerations when undertaking window completion projects in subterranean environments. Adhering to these points can improve overall quality and longevity.

Tip 1: Ensure Proper Framing: Construct framing with pressure-treated lumber to resist moisture and decay. Accurate measurements are vital for a secure and weather-tight installation.

Tip 2: Implement Effective Insulation: Utilize rigid foam insulation or spray foam around the framed opening. This minimizes thermal bridging and significantly reduces energy loss.

Tip 3: Employ a Robust Moisture Barrier: Install a waterproof membrane to prevent water intrusion from the surrounding soil. Overlap seams thoroughly and seal any penetrations.

Tip 4: Select Appropriate Glazing: Opt for insulated glass units (IGUs) with low-E coatings to improve energy performance and reduce condensation.

Tip 5: Ensure Adequate Drainage: Verify that the exterior window well has proper drainage to prevent water accumulation. Consider adding gravel at the base of the well for optimal water flow.

Tip 6: Choose Durable Interior Finishes: Select moisture-resistant drywall and paint to prevent mold growth. PVC trim is also a viable alternative to wood in high-humidity environments.

Tip 7: Prioritize Proper Ventilation: Ensure the area has adequate ventilation to reduce humidity and prevent the build-up of indoor pollutants. Consider installing a small exhaust fan.

Tip 8: Comply with Local Building Codes: Consult local building codes and regulations to ensure that the window installation meets all safety and structural requirements.

Following these guidelines contributes to a more energy-efficient, comfortable, and durable subterranean living space. Careful planning and execution are key to a successful project.

The subsequent section addresses specific material selections and advanced techniques for maximizing the benefits of well-executed subterranean window enhancements.

1. Framing Material Selection

The choice of materials for framing openings below ground level directly affects the long-term structural integrity, energy efficiency, and overall success of subterranean window completion. Careful consideration must be given to the unique environmental challenges presented by below-grade conditions.

- Pressure-Treated Lumber Selection

Pressure-treated lumber is essential due to its resistance to rot, decay, and insect infestation, all of which are prevalent in below-grade environments. The level of treatment should be appropriate for direct soil contact. Using untreated lumber will lead to premature failure of the frame, compromising the entire window installation and potentially leading to significant structural damage. Example: Chromated Copper Arsenate (CCA) treated lumber was once commonly used but has been largely replaced by newer, safer alternatives like Alkaline Copper Quaternary (ACQ) for residential applications.

- Metal Framing Considerations

Metal framing, while durable, is susceptible to corrosion in damp environments. If used, it requires proper corrosion-resistant coatings and careful detailing to prevent moisture intrusion and subsequent rust. Dissimilar metal contact should also be avoided to prevent galvanic corrosion. Example: Using galvanized steel studs in conjunction with a robust moisture barrier can provide a durable framing solution. However, inadequate protection can lead to rapid deterioration, particularly in areas with high soil acidity.

- Composite Framing Options

Composite framing materials, made from recycled plastics or wood fibers combined with polymers, offer excellent moisture resistance and are not susceptible to rot or insect damage. They can be a viable alternative to traditional lumber, especially in demanding below-grade applications. Example: Using a composite lumber product for the window sill, which is often exposed to the most moisture, can significantly extend the lifespan of the installation. However, these materials may have different load-bearing capabilities than traditional lumber and require careful consideration of the structural design.

- Impact on Insulation Performance

The framing material also influences the performance of the insulation. Metal framing, for instance, is a highly conductive material that can create thermal bridges, reducing the overall R-value of the wall assembly. Wood and composite framing materials generally have lower thermal conductivity. Example: Using a continuous layer of rigid foam insulation on the exterior of the framing, regardless of the material, can help to mitigate thermal bridging and improve the overall energy efficiency of the subterranean window installation.

Selecting the appropriate framing material is a critical step in the window completion process. Failure to adequately address the moisture and environmental challenges inherent in below-grade applications will compromise the long-term performance of the window and the surrounding structure, ultimately undermining the investment in a finished basement.

2. Insulation Type and R-Value

The selection of insulation type and its corresponding R-value are critical determinants of energy efficiency and comfort in finished subterranean spaces, particularly in the context of window completion. Proper insulation mitigates heat transfer, reduces condensation, and contributes to a stable indoor environment.

- Rigid Foam Insulation

Rigid foam boards, such as extruded polystyrene (XPS) or expanded polystyrene (EPS), offer high R-values per inch of thickness and are relatively moisture resistant. They are often applied directly to the exterior of the foundation wall, providing a continuous thermal barrier. This approach minimizes thermal bridging and can significantly reduce energy loss. Example: Installing a 2-inch XPS board with an R-value of 10 per inch around the window frame effectively isolates the window opening from the surrounding concrete, reducing heat loss in winter and heat gain in summer. Improper installation, however, can compromise its effectiveness.

- Spray Foam Insulation

Spray foam, either open-cell or closed-cell, provides excellent air sealing and insulation properties. Closed-cell foam has a higher R-value per inch and is more resistant to moisture absorption, making it suitable for below-grade applications. Spray foam effectively fills gaps and crevices around the window frame, creating a tight seal that minimizes air infiltration. Example: Applying closed-cell spray foam around the perimeter of a window frame creates an airtight seal, preventing drafts and reducing condensation. However, proper ventilation is crucial to manage potential off-gassing and moisture accumulation within the wall cavity.

- Fiberglass Batt Insulation

Fiberglass batt insulation is a more traditional option, but it is less effective in below-grade applications due to its susceptibility to moisture absorption and air infiltration. When exposed to moisture, fiberglass loses its R-value and can promote mold growth. Example: Using fiberglass batts in a subterranean window framing without a proper vapor barrier can lead to significant moisture accumulation, reducing its insulation effectiveness and potentially causing structural damage. It is generally not recommended for direct contact with concrete walls.

- R-Value Requirements and Code Compliance

Local building codes often specify minimum R-value requirements for basement walls and windows. These requirements vary depending on climate zone and construction type. Selecting an insulation material with an appropriate R-value ensures compliance with building codes and maximizes energy savings. Example: A building code may require a minimum R-value of R-13 for basement walls in a specific climate zone. Achieving this R-value may necessitate using a combination of insulation materials or selecting a higher-density insulation product. Furthermore, ensuring proper installation is just as critical as the R-value itself to achieve the desired thermal performance.

In conclusion, the selection of insulation type and R-value for window enhancements necessitates careful consideration of moisture resistance, air sealing capabilities, and compliance with local building codes. A well-insulated window installation not only improves energy efficiency but also contributes to a more comfortable and durable subterranean living space. Ignoring these critical factors will inevitably lead to increased energy costs, potential moisture-related problems, and compromised structural integrity.

3. Moisture Barrier Effectiveness

The efficacy of a moisture barrier is paramount to the long-term performance and habitability of below-grade spaces, particularly in the context of window completion. Subterranean environments are inherently susceptible to moisture intrusion, necessitating robust barriers to prevent water damage and maintain a healthy indoor environment.

- Types of Moisture Barriers and Their Application

Various moisture barrier options exist, each with distinct properties and applications. These include liquid-applied membranes, sheet membranes, and vapor retarders. Liquid-applied membranes form a seamless, monolithic barrier when properly installed, offering excellent protection against water intrusion around window openings. Sheet membranes, typically composed of polyethylene or modified bitumen, provide a durable barrier but require careful detailing at seams and penetrations. Vapor retarders, while primarily intended to control vapor diffusion, can also contribute to moisture protection. The selection of an appropriate barrier depends on site-specific conditions, soil composition, and hydrostatic pressure. For instance, a high water table may necessitate a more robust barrier system than a well-drained site.

- Proper Installation Techniques

Even the most effective moisture barrier will fail if improperly installed. Adhering to manufacturer specifications and industry best practices is critical. This includes surface preparation, proper overlap of seams, and sealing of penetrations. Thoroughly cleaning and priming the substrate ensures proper adhesion of the barrier. Overlapping seams according to the manufacturer’s instructions prevents water intrusion through weak points. Sealing penetrations, such as pipes or conduits, with compatible sealants prevents water from entering the structure. Neglecting these details can compromise the integrity of the barrier and lead to water damage. Example: A poorly sealed penetration around a window frame can allow water to wick into the surrounding wall assembly, leading to mold growth and structural deterioration.

- Impact on Indoor Air Quality

A properly functioning moisture barrier is essential for maintaining healthy indoor air quality in finished subterranean spaces. Excess moisture promotes mold growth, which can release spores into the air and trigger allergic reactions or respiratory problems. By preventing water intrusion, a moisture barrier helps to create a dry and healthy indoor environment. Example: A basement with persistent moisture problems often exhibits a musty odor and visible mold growth on walls and ceilings, negatively impacting indoor air quality and occupant health. Conversely, a basement with an effective moisture barrier remains dry and free from mold, promoting a healthy and comfortable living space.

- Long-Term Durability and Maintenance

The long-term durability of a moisture barrier depends on the quality of the materials used and the effectiveness of the installation. Regular inspection and maintenance are essential for identifying and addressing any potential problems. Cracks, punctures, or deterioration of the barrier should be promptly repaired to prevent water intrusion. Proper drainage around the foundation also contributes to the longevity of the moisture barrier by reducing hydrostatic pressure. Example: Routine inspection of the exterior foundation walls and window wells can reveal potential problems, such as cracks or standing water. Addressing these issues promptly can prevent water from penetrating the moisture barrier and causing damage to the structure.

In conclusion, the implementation of a robust and properly installed moisture barrier is indispensable for successful subterranean window completion. Its effectiveness directly impacts the structural integrity, energy efficiency, and indoor air quality of the finished space. Neglecting this critical aspect can lead to costly repairs, health problems, and a compromised living environment.

4. Glazing unit performance

The performance characteristics of glazing units are intrinsically linked to the successful completion of subterranean window installations. The selection of appropriate glazing directly influences energy efficiency, condensation resistance, and the amount of natural light entering the space. Inferior glazing can lead to significant heat loss in winter, excessive heat gain in summer, and potential moisture problems, undermining the overall goals of a finished basement.

For instance, single-pane glazing offers minimal insulation, resulting in substantial energy transfer and increased heating and cooling costs. Double-pane units with low-emissivity (low-E) coatings and gas fills (e.g., argon or krypton) provide significantly improved thermal performance by reducing radiative heat transfer and convection. Condensation resistance is another critical factor, particularly in the humid environment often found below grade. High-performance glazing units help maintain warmer interior surface temperatures, minimizing the likelihood of condensation formation and preventing potential mold growth. Furthermore, the type of glass used, such as tempered or laminated glass, can enhance safety and security, especially for egress windows. Consider a scenario where standard, non-tempered glass is used in an egress window; in the event of breakage, it can pose a significant safety hazard during an emergency evacuation. Properly selected glazing, therefore, contributes to both energy efficiency and occupant safety.

Ultimately, the glazing unit performance is not merely an aesthetic consideration but a fundamental component of the overall window system’s functionality. Choosing appropriate glazing enhances the comfort, energy efficiency, and safety of the finished basement, demonstrating the practical significance of understanding its role in subterranean window completion. Poor glazing selection, conversely, can negate the benefits of other improvements, leading to long-term problems and diminished value.

5. Exterior well drainage

Effective exterior well drainage is intrinsically linked to the successful completion of subterranean window installations. The presence of accumulated water in a window well directly impacts the lifespan and performance of the window system and the adjacent basement structure. Inadequate drainage results in hydrostatic pressure against the window and foundation, potentially leading to water infiltration through the window frame, sill, or surrounding wall. This intrusion can cause damage to interior finishes, promote mold growth, and compromise the structural integrity of the foundation. For example, a window well lacking proper drainage in a region with frequent rainfall is highly susceptible to water accumulation, which can then seep into the basement, damaging drywall, carpeting, and personal belongings. Consequently, properly designed and maintained exterior well drainage is not merely an ancillary consideration, but a critical component of a comprehensive finishing strategy.

The implementation of effective drainage solutions typically involves a multi-faceted approach. This includes ensuring a properly graded slope away from the foundation to divert surface water, installing a gravel base within the well to facilitate drainage, and connecting the well to a subsurface drainage system, such as a perimeter drain or sump pump. The choice of drainage method depends on site-specific conditions, including soil type, groundwater levels, and proximity to underground utilities. Neglecting these considerations can render drainage efforts ineffective. For example, installing a gravel base in a clay-rich soil without a connection to a drainage system will likely result in a clogged well and continued water accumulation. Furthermore, regular maintenance, such as removing debris and ensuring clear drainage pathways, is essential for maintaining the long-term effectiveness of the system.

In summation, the integration of robust exterior well drainage into the overall window finishing process is paramount for mitigating water damage and preserving the integrity of subterranean spaces. This proactive approach not only safeguards the investment in a finished basement but also contributes to a healthier and more comfortable living environment. A failure to address drainage concerns adequately can lead to recurring problems and costly repairs, underscoring the practical significance of prioritizing effective water management strategies.

6. Interior finish durability

The longevity and performance of interior finishes are directly influenced by the quality of subterranean window completion. Proper execution minimizes moisture-related issues, contributing significantly to the sustained integrity of interior materials.

- Moisture-Resistant Drywall

Subterranean environments are prone to elevated humidity levels and potential water intrusion. Traditional drywall is highly susceptible to moisture damage, leading to structural deterioration and mold growth. Employing moisture-resistant drywall, often referred to as “green board” or “blue board,” provides enhanced protection against these threats. Its non-absorbent core resists water penetration, minimizing the risk of degradation. In subterranean window completion, utilizing moisture-resistant drywall around the window frame is crucial for preventing moisture from wicking into the wall assembly and compromising the finish. Failure to use appropriate drywall can result in costly repairs and health hazards.

- Mold-Inhibiting Paints and Primers

Even with moisture-resistant drywall, the potential for mold growth remains a concern in subterranean spaces. Mold-inhibiting paints and primers contain biocides that suppress the growth of mold spores, providing an additional layer of protection. These coatings are specifically formulated to resist moisture and prevent the proliferation of mold colonies. When finishing window frames and surrounding walls, applying mold-inhibiting paints and primers helps to maintain a healthy indoor environment and extend the lifespan of the interior finishes. Neglecting this step can lead to unsightly mold stains, unpleasant odors, and potential health problems for occupants.

- Durable Trim and Molding Materials

Window trim and molding are often exposed to moisture and physical impact, making the selection of durable materials essential. Wood trim is susceptible to rot and insect damage in subterranean environments, requiring frequent maintenance and eventual replacement. Alternatives such as PVC or composite trim offer superior moisture resistance and durability. These materials are impervious to rot, decay, and insect infestation, ensuring long-lasting performance. Furthermore, they require minimal maintenance, reducing the overall cost of ownership. In completing subterranean windows, opting for PVC or composite trim provides a robust and aesthetically pleasing finish that withstands the challenges of a below-grade environment.

- Waterproof Window Sills

The window sill is particularly vulnerable to water damage, as it is directly exposed to moisture from condensation and potential leaks. Selecting a waterproof material for the sill is crucial for preventing water from penetrating the wall assembly. Options such as solid-surface materials, tile, or epoxy coatings provide an impenetrable barrier against water intrusion. These materials are durable, easy to clean, and resistant to staining. In completing subterranean windows, installing a waterproof sill ensures long-term protection against water damage and maintains the integrity of the interior finishes. A properly sealed sill prevents water from wicking into the wall cavity, safeguarding the surrounding structure and preventing mold growth.

The enduring quality of interior finishes relies heavily on the meticulous execution of window completion, particularly regarding moisture management. Addressing these facets minimizes long-term maintenance and guarantees a habitable, healthy basement environment.

Frequently Asked Questions

The following addresses common inquiries and clarifies key considerations regarding the proper completion of lower-level window installations.

Question 1: Is specialized knowledge necessary for completing subterranean window installations?

While basic handyman skills may suffice for superficial cosmetic improvements, a comprehensive understanding of building codes, moisture management, and structural integrity is crucial for a lasting and safe result. Engaging a qualified contractor is advisable, particularly for structural modifications or complex moisture mitigation strategies.

Question 2: What are the principal benefits of proper window completion below grade?

Principal benefits include enhanced energy efficiency, improved natural lighting, increased usable living space, mitigation of moisture-related problems, and heightened property value. Adequately finished installations contribute to a healthier and more comfortable interior environment, while poorly executed work can lead to structural damage and health hazards.

Question 3: Does finishing subterranean windows necessitate obtaining building permits?

Local regulations vary, but altering window openings, particularly if it impacts structural load-bearing elements or egress requirements, often mandates obtaining building permits. Contacting the local building department before initiating any work is prudent to ensure code compliance and avoid potential fines or delays.

Question 4: Which insulation type offers the most effective moisture resistance in below-grade window applications?

Closed-cell spray foam insulation generally provides superior moisture resistance due to its inherent water-repellent properties and ability to create an airtight seal. Rigid foam insulation, properly installed with sealed seams, also offers good moisture resistance. However, fiberglass batt insulation is generally not recommended for below-grade applications due to its susceptibility to moisture absorption.

Question 5: How frequently should the exterior window well drainage be inspected and maintained?

Exterior window well drainage should be inspected at least twice annually, typically in the spring and fall, to ensure clear drainage pathways and remove accumulated debris. More frequent inspections may be necessary in areas prone to heavy rainfall or snowfall. Neglecting regular maintenance can lead to water accumulation and potential basement flooding.

Question 6: What are the potential consequences of neglecting proper moisture management during window completion?

Neglecting proper moisture management can lead to a cascade of problems, including mold growth, structural damage to framing and drywall, reduced insulation effectiveness, compromised indoor air quality, and costly repairs. In severe cases, chronic moisture issues can render the basement uninhabitable and necessitate extensive remediation efforts.

Proper subterranean window completion requires a holistic approach encompassing structural considerations, moisture control, and adherence to local building codes. A well-executed installation ensures a safe, comfortable, and energy-efficient living space.

The subsequent article section delves into the economic aspects and returns on investment associated with high-quality window improvements below grade.

Concluding Remarks on Subterranean Window Enhancements

This discourse has systematically explored critical facets of completing window installations below ground level. Emphasis has been placed on framing material selection, insulation strategies, moisture barrier implementation, glazing unit performance, exterior well drainage, and interior finish durability. Successful integration of these elements yields substantial benefits in energy efficiency, structural preservation, and enhanced habitability. The absence of rigorous execution invites predictable and costly consequences.

Prudent homeowners must prioritize comprehensive planning and execution. While superficially appealing, cost-cutting measures often compromise the long-term integrity of the structure and negate potential benefits. Investing in qualified professionals and proven techniques guarantees a return that extends beyond mere aesthetics, safeguarding the basement environment and the overall value of the property. The choice to pursue these improvements responsibly will directly impact the long-term health and well-being of the residence.