The act of replicating the aesthetic of Pottery Barn furniture through do-it-yourself methods involves various techniques to achieve a distressed, aged, or otherwise characteristically textured surface. This process often includes layering paint, stain, and protective coatings, followed by controlled abrasion or other manipulation to reveal underlying layers and create a sense of depth and antiquity. For instance, a plain wooden table can be transformed using chalk paint, dark wax, and sandpaper to mimic the look of a reclaimed wood piece often associated with the retail brand.

Reproducing high-end furniture finishes through independent efforts offers several advantages, including cost savings, customization options, and the satisfaction of crafting unique home dcor. Historically, the pursuit of replicating expensive finishes has been driven by economic factors and a desire for personalized expression. The ability to achieve a desired look without incurring significant expense empowers individuals to adapt their living spaces to current trends and personal preferences while reducing reliance on mass-produced items.

Subsequent sections will delve into specific methods for achieving this desired aesthetic, detailing the tools, materials, and step-by-step procedures required for successful execution. Detailed explanations regarding surface preparation, paint application, distressing techniques, and sealant options will be provided, offering a comprehensive guide to creating furniture with a similar look and feel.

Essential Considerations for Achieving a Similar Furniture Aesthetic

The following recommendations are designed to guide individuals in replicating a specific furniture style through independent means. Proper execution requires careful planning and adherence to established best practices.

Tip 1: Surface Preparation is Paramount: Thoroughly clean and sand the furniture piece before applying any finishes. Failure to remove existing coatings or imperfections will compromise the final result.

Tip 2: Select Appropriate Paint Types: Chalk paint or milk paint are often preferred due to their matte finish and ease of distressing. Consider the intended use of the furniture when selecting a paint type.

Tip 3: Layer Finishes for Depth: Apply multiple thin layers of paint or stain, allowing each layer to dry completely before proceeding. This technique creates visual interest and allows for selective distressing.

Tip 4: Employ Distressing Techniques Judiciously: Utilize sandpaper, steel wool, or other abrasive tools to selectively remove paint and reveal underlying layers. Exercise caution to avoid over-distressing the piece.

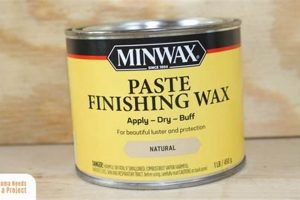

Tip 5: Utilize Glazes and Waxes for Added Character: Apply a dark wax or glaze to highlight details and create an aged appearance. Buff the finish to achieve the desired sheen.

Tip 6: Protect the Finish with a Topcoat: Apply a clear sealant or varnish to protect the painted or stained surface from wear and tear. Choose a topcoat with a matte or satin finish to maintain the desired aesthetic.

Tip 7: Experiment with Color Palettes: Explore various color combinations to achieve the desired aesthetic. Consider using neutral colors with subtle variations to create a sophisticated look.

By implementing these strategies, individuals can effectively create furniture pieces that closely resemble the aesthetic associated with a popular retail brand. The key lies in careful attention to detail and a willingness to experiment with different techniques.

The subsequent sections will provide more detailed information on specific distressing techniques and finish options. These insights will offer the ability to create personalized furniture pieces.

1. Paint Layering

Paint layering is a fundamental technique in replicating the aged and textured aesthetic often associated with Pottery Barn furniture through do-it-yourself projects. The strategic application of multiple paint coats, each potentially of a different color or type, contributes significantly to the final visual effect. This approach allows for controlled distressing, revealing underlying colors and textures to create a sense of depth and character.

- Base Coat Application

The initial layer of paint, the base coat, serves as the foundation for subsequent layers. This layer typically provides overall color and adhesion for the layers to follow. In the context of achieving a furniture style, the base coat is often a neutral color that will subtly peek through distressed areas, creating a weathered appearance. The choice of primer and paint is crucial for durability.

- Accent Color Application

Accent colors are applied over the base coat to introduce contrast and complexity. These layers might involve dry brushing, stippling, or washing techniques to create subtle variations in tone and texture. The selection of accent colors plays a critical role in emulating the desired aesthetic, often involving muted tones or shades that complement the base coat. Distressing techniques later reveal these layers.

- Distressing Mediums and Techniques

The effectiveness of paint layering hinges on the application of appropriate distressing techniques. Sandpaper, steel wool, or chemical strippers are used to selectively remove top layers of paint, exposing the underlying colors and textures. The degree and placement of distressing are carefully controlled to mimic natural wear and tear, contributing to the authenticity of the replicated finish. Strategic use of these mediums and techniques is essential.

- Protective Clear Coats

Once the desired paint layering and distressing effects are achieved, a clear coat is applied to protect the finish and ensure its longevity. Clear coats, available in matte, satin, or gloss finishes, provide a barrier against scratches, moisture, and UV damage. The choice of clear coat influences the final appearance, with matte finishes often preferred to maintain a vintage or rustic aesthetic while also adding protection to the replicated finish.

In summary, paint layering is an integral component in achieving a similar furniture aesthetic. Each layer, from the base coat to the protective topcoat, plays a crucial role in creating depth, texture, and durability. Mastery of paint layering techniques provides individuals with the ability to create customized furniture pieces that emulate the look and feel of high-end retail items at a fraction of the cost.

2. Controlled Distressing

Controlled distressing, a deliberate process of adding artificial wear and imperfections to furniture, is a critical component in replicating the aesthetic commonly associated with Pottery Barn through do-it-yourself endeavors. The technique aims to mimic the appearance of age, use, and weathering, thereby imparting character and visual interest to newly finished or repurposed pieces.

- Strategic Abrasion

Strategic abrasion involves the selective removal of paint or finish using tools such as sandpaper, steel wool, or sanding blocks. The goal is not to uniformly strip the surface, but rather to concentrate abrasion on edges, corners, and areas where natural wear would typically occur. For instance, on a painted wooden table, sandpaper might be applied to the table’s edges and around the legs to simulate years of contact and use. This approach requires a careful understanding of how furniture naturally ages.

- Layering and Revealing

This facet involves applying multiple layers of paint or finish, each with a slightly different color or texture. The distressing process then reveals these underlying layers, creating depth and complexity in the finish. An example would be applying a base coat of dark gray paint, followed by a topcoat of light cream paint. Sanding through the cream paint in select areas exposes the dark gray underneath, simulating a worn topcoat over an older, darker base. This technique adds authenticity to the imitated finish.

- Intentional Imperfections

Creating intentional imperfections involves adding small dents, scratches, or other marks to the furniture surface before or during the finishing process. These imperfections contribute to the overall distressed look by simulating the effects of time and use. For instance, a hammer and nail can be used to create small dents in the wood, or a wire brush can be used to add scratches. These imperfections are strategically placed to enhance the realism of the distressed finish.

- Application of Antiquing Products

The use of antiquing glazes, waxes, or stains can enhance the distressed appearance by highlighting textures and adding a patina of age. These products are typically applied after the paint and distressing have been completed. For example, a dark wax can be applied to a painted surface and then wiped away, leaving residue in the crevices and distressed areas, which darkens them and emphasizes the texture. This process creates a more convincing simulation of age and wear.

These techniques, when applied with careful consideration, enable individuals to recreate the specific furniture style in an economical and personalized manner. The overall success depends on understanding how the individual techniques interact and contribute to a cohesive aesthetic that emulates furniture acquired from retail channels that sell distressed furniture.

3. Wax Application

Wax application constitutes a crucial step in replicating the aesthetic of Pottery Barn furniture through do-it-yourself methods. The application of wax serves multiple purposes, contributing significantly to the final visual appeal and durability of the piece.

- Enhancement of Distressed Finishes

Wax applied over painted and distressed surfaces accentuates the texture and imperfections created during the distressing process. The wax settles into the crevices and abraded areas, darkening them and highlighting the simulated wear. For example, on a chalk-painted cabinet, dark wax can be applied and then partially removed, leaving a subtle antique effect that enhances the rustic aesthetic often associated with the retail brand’s style. This accentuation adds depth and visual interest to the furniture.

- Protection and Sealing

Wax provides a protective layer over the paint or stain, safeguarding the finish from moisture, scratches, and everyday wear. While not as durable as a polyurethane sealant, wax offers a softer, more natural look that aligns with the desired style. A properly waxed surface resists minor spills and abrasions, extending the life of the finish. Regular reapplication of wax is necessary to maintain this protection.

- Buffing to Achieve Desired Sheen

Following the application of wax, buffing is essential to achieve the desired sheen. The degree of buffing determines the level of reflectivity and smoothness of the surface. A light buffing results in a matte finish, while more vigorous buffing produces a subtle sheen. The choice of sheen influences the overall aesthetic, with matte or low-sheen finishes often preferred for furniture seeking to emulate the Pottery Barn style. This sheen contributes to the authentic, aged appearance.

- Adding Depth and Patina

Colored waxes, such as antique brown or black, can be used to add depth and patina to the finish. These waxes fill in the distressed areas and create subtle variations in color, enhancing the aged appearance of the furniture. For instance, applying a dark wax to a piece painted in a light color can create a contrast that emphasizes the texture and imperfections, replicating the look of furniture that has aged naturally over time. This effect contributes to the perception of authenticity.

In conclusion, the appropriate application of wax significantly impacts the overall success of replicating a specific furniture aesthetic. The selection of wax type, the method of application, and the degree of buffing all contribute to the final appearance and durability, effectively creating furniture pieces with a similar look to those from retail stores specializing in this type of design.

4. Color Palette

The successful execution hinges significantly on the selection and application of an appropriate color palette. The retailer’s furniture often features muted, neutral tones, and recreating this aesthetic requires careful consideration of color harmony and the interplay between different shades and hues. Employing colors that reflect natural materials, such as grays, creams, beiges, and muted blues or greens, is crucial for achieving the desired visual effect. An ill-chosen color palette can detract from the authenticity of the final piece, regardless of the quality of the distressing or finishing techniques employed. For instance, using overly bright or saturated colors will result in a product that deviates significantly from the intended aesthetic.

The practical application of a well-considered color palette involves not only selecting individual colors but also understanding how they interact when layered or distressed. A common technique involves applying a darker base coat followed by a lighter topcoat, which is then selectively removed to reveal the underlying color. This layering effect necessitates choosing colors that complement each other, creating visual depth and interest. Furthermore, the color palette extends beyond the main furniture piece to encompass hardware, accents, and surrounding decor. Coordinating these elements enhances the overall effect, resulting in a cohesive and visually appealing living space. Examples include using dark bronze hardware with a cream-colored painted finish or incorporating natural fiber rugs and textiles to complement the muted color scheme.

The connection between color palette and the process underscores the importance of deliberate color choices. A harmonious and carefully selected color scheme contributes significantly to the authenticity and overall success of the project. While challenges may arise in accurately replicating specific colors or achieving a consistent finish, understanding the underlying principles of color theory and carefully experimenting with different combinations can mitigate these issues. Ultimately, a well-executed color palette is a defining characteristic that enables the creation of furniture that closely resembles the sought-after aesthetic, allowing for personalized adaptations while maintaining the essence of the style.

5. Surface Preparation

Surface preparation is a foundational component for replicating the aesthetic through do-it-yourself projects. The quality of the final finish is directly and significantly influenced by the initial condition of the substrate. Inadequate surface preparation inevitably leads to adhesion problems, uneven finishes, and a compromised aesthetic that deviates significantly from the intended goal. For instance, if an existing varnish is not properly sanded or removed prior to applying chalk paint, the new paint may not adhere correctly, resulting in chipping or peeling, thus undermining the desired appearance.

Effective surface preparation encompasses several critical steps. Cleaning the surface to remove dirt, grease, and contaminants is paramount, often requiring the use of specialized cleaning solutions or degreasers. Sanding is then necessary to create a uniform texture that promotes paint adhesion; the appropriate grit sandpaper must be selected based on the existing finish and the desired level of distress. Priming may also be required to seal porous surfaces, block stains, or enhance adhesion, depending on the type of material being refinished. Consider, for example, the restoration of an old oak dresser. If the original surface is not thoroughly cleaned and sanded, any applied paint or stain will likely exhibit uneven absorption and a lack of durability. Proper preparation would include stripping the old finish, sanding the wood smooth, and applying a suitable primer before proceeding with the finishing steps.

In summary, surface preparation represents a critical investment of time and effort that directly impacts the quality and longevity of a particular furniture project. While the appeal of shortcutting this step may be tempting, neglecting proper surface preparation will ultimately compromise the project’s success. By recognizing the importance of this foundational element and adhering to established best practices, individuals can maximize the likelihood of achieving a high-quality, professional-looking furniture piece that emulates the desired aesthetic. It also ensures that the refinished pieces lasts for a longer time.

6. Protective Sealing

Protective sealing functions as a crucial final step in replicating the sought-after furniture finish. Without an appropriate sealant, the effort invested in layering, distressing, and waxing is vulnerable to premature wear and damage. The absence of a protective barrier renders the finish susceptible to scratches, moisture damage, and staining from everyday use. As a direct consequence, the intended aged or rustic appearance can degrade rapidly and unevenly, failing to maintain the aesthetic associated with the retail brand.

The selection of a suitable sealant is determined by the type of paint or finish used and the intended application of the furniture piece. For projects employing chalk paint, a wax sealant is often chosen to maintain the matte finish and enhance the aged aesthetic. In contrast, water-based polyurethanes offer a more durable and water-resistant barrier, making them suitable for surfaces exposed to frequent use or moisture. Regardless of the sealant type, proper application techniques, including thin, even coats and adequate drying time, are critical. Failure to adhere to these practices can result in cloudiness, uneven sheen, or compromised protection. For example, applying a thick coat of polyurethane can lead to drips and uneven drying, detracting from the desired aesthetic and compromising the protective qualities of the sealant.

In summary, protective sealing is not merely an optional add-on but an integral component of this process. Its role extends beyond preserving the visual appeal, it maintains the integrity and longevity of the finished piece. Proper selection and application of a sealant are essential to safeguarding the investment of time, effort, and materials, ensuring that the completed furniture item retains its intended appearance and withstands the rigors of daily use. Furthermore, it provides a lasting finish that is easy to care for and maintain.

Frequently Asked Questions

The following questions address common inquiries regarding the replication of a distinctive furniture aesthetic through do-it-yourself techniques. Understanding these points is crucial for successful project execution.

Question 1: What specific types of paint are best suited for mimicking a distressed, aged furniture look?

Chalk paint and milk paint are frequently recommended due to their matte finish and ease of distressing. These paints readily accept waxes and glazes, enhancing the aged appearance.

Question 2: How can one effectively control the degree of distressing to avoid an overly artificial appearance?

Employ a gradual approach using fine-grit sandpaper, focusing on edges, corners, and areas of natural wear. Regularly assess the progress to ensure a balanced and authentic look.

Question 3: What is the most reliable method for ensuring proper paint adhesion when working with existing furniture?

Thorough surface preparation is paramount. This includes cleaning, sanding to create a uniform texture, and potentially applying a primer to promote adhesion and block stains.

Question 4: Is a topcoat sealant always necessary, and what type is most appropriate for a distressed finish?

A topcoat is generally recommended to protect the finish from wear and tear. Matte or satin polyurethanes provide durability while preserving the aged aesthetic. Wax sealants offer a softer look but require periodic reapplication.

Question 5: How important is color selection in achieving a specific furniture style?

Color selection is critical. Muted, neutral tones such as grays, creams, and beiges are frequently used to emulate the natural, understated elegance associated with the furniture aesthetic.

Question 6: What are some common mistakes to avoid when attempting to replicate a distressed furniture finish?

Over-distressing, using overly bright or saturated colors, neglecting surface preparation, and applying sealants improperly are common pitfalls. Careful planning and attention to detail mitigate these risks.

These FAQs provide a foundation for navigating the complexities of recreating a sought-after furniture style. By understanding these key considerations, individuals enhance their prospects of achieving a successful and visually appealing outcome.

The subsequent section will explore specific techniques and strategies for achieving a particular furniture finish, offering practical guidance for project implementation.

Achieving a Specific Furniture Aesthetic

This exploration of replicating a furniture finish through independent means has underscored several critical factors. The success of replicating a specific furniture style hinges on understanding the nuances of surface preparation, paint layering techniques, controlled distressing methods, wax application, strategic color palette selection, and the necessity of a protective sealant. Each step contributes to the overall aesthetic, and mastering these elements enables individuals to create furniture pieces that effectively emulate the desired look.

The ability to achieve a high-end furniture aesthetic through “pottery barn finish diy” offers both economic and creative benefits. While challenges may arise, a thorough understanding of the processes involved will allow for creative expression. Continued exploration and refinement of these skills will contribute to both the quality and longevity of the finished products.