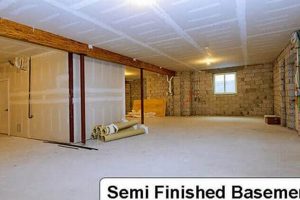

Completing a lower level space involves a sequence of actions transforming an unfinished area into a functional and habitable part of a residence. This process often includes framing walls, installing insulation, running electrical and plumbing systems, and finishing the surfaces with drywall, flooring, and paint. For instance, a homeowner might decide to convert their underutilized storage area into a recreational room, home office, or additional living quarters, thereby increasing the overall living space and value of the property.

Undertaking such a project provides several advantages, including increased property value, expanded living space, and the opportunity to customize the area to meet specific needs and preferences. Historically, improving unused lower levels has been a popular way to expand homes without incurring the expenses and complexities of building an addition. The added square footage can significantly enhance a home’s marketability and appeal to potential buyers.

Understanding the correct order and methods for carrying out these tasks is essential for a successful outcome. Subsequent sections will detail the key phases involved, from initial planning and permitting to final inspections, ensuring adherence to building codes and best practices for a safe and aesthetically pleasing result.

Essential Guidance for Lower Level Completion

This section presents key recommendations to optimize the process of completing a lower level area, enhancing efficiency and minimizing potential challenges.

Tip 1: Develop a Comprehensive Plan: A detailed blueprint, outlining the desired layout, functionality, and aesthetic, is crucial. This plan should incorporate structural considerations, mechanical systems, and compliance with local building codes.

Tip 2: Secure Necessary Permits: Prior to commencing any work, it is imperative to obtain all required permits from the local governing body. Failure to do so can result in costly delays, fines, or mandatory remediation.

Tip 3: Address Moisture Issues: Moisture penetration can lead to structural damage and health concerns. Prior to commencing work, identify and rectify any sources of water intrusion through proper waterproofing techniques and drainage solutions.

Tip 4: Prioritize Insulation: Proper insulation is paramount for energy efficiency and comfort. Employ insulation materials appropriate for below-grade applications, ensuring effective thermal and moisture barriers.

Tip 5: Ensure Proper Ventilation: Adequate ventilation is crucial for maintaining air quality and preventing the buildup of moisture and pollutants. Consider incorporating mechanical ventilation systems, such as exhaust fans or heat recovery ventilators (HRVs).

Tip 6: Adhere to Electrical Codes: Electrical work must be performed by a qualified professional, adhering to all relevant codes and regulations. Ground fault circuit interrupters (GFCIs) are essential for safety in damp locations.

Tip 7: Consider Soundproofing: To minimize noise transmission to and from the space, incorporate soundproofing measures, such as resilient channels, dense insulation, and solid-core doors.

Effectively implementing these strategies will contribute to a smoother construction process, a more comfortable living environment, and increased property value.

The subsequent section will discuss common challenges encountered during lower-level completion and provide strategies for effective mitigation.

1. Planning and Design

Comprehensive planning and design are foundational to any successful effort to complete an unfinished lower level. A well-defined strategy, encompassing structural integrity, functionality, and aesthetic considerations, is paramount before initiating any physical alterations.

- Spatial Layout Optimization

Optimizing the arrangement of rooms and areas within the space is crucial for maximizing usability and flow. Considerations should include room sizes, traffic patterns, and the incorporation of natural light sources. For example, a design might prioritize an open-concept layout for a recreational area or dedicate a smaller, enclosed space for a home office. Improper layout design can result in a dysfunctional space, negating the benefits of completion.

- Code Compliance and Safety

A thorough plan must address all applicable building codes and safety regulations. This includes egress requirements, fire safety measures, and proper ventilation. For instance, ensuring adequate emergency exits and installing smoke detectors are critical safety measures. Failure to comply with these regulations can lead to legal issues and compromise the safety of occupants.

- Material Selection and Budgeting

Careful selection of materials is essential for both aesthetic appeal and long-term durability. The design process should include a detailed materials list with associated costs to ensure the project remains within budget. Choosing moisture-resistant materials, for example, is critical in below-grade environments to prevent mold growth. Inadequate budgeting or inappropriate material selection can lead to cost overruns and structural issues.

- Mechanical Systems Integration

The integration of HVAC, plumbing, and electrical systems requires careful planning to ensure efficient and safe operation. The design should incorporate considerations such as ductwork routing, plumbing fixture locations, and electrical outlet placement. Poorly integrated mechanical systems can result in inefficient energy usage, inadequate climate control, and potential safety hazards.

These facets collectively emphasize the critical role of planning and design in the overall project. A meticulous approach to these elements will significantly contribute to a successful and functional space.

2. Permitting

Permitting is an indispensable component of the overall process to complete an unfinished lower level. It represents a regulatory requirement ensuring that all construction activities adhere to established building codes and safety standards, safeguarding both current and future occupants.

- Code Compliance Verification

The permitting process serves as a mechanism for local authorities to verify that proposed alterations align with prevailing building codes. This includes assessments of structural integrity, fire safety, and adherence to accessibility guidelines. For example, a permit application might require detailed structural plans reviewed by a licensed engineer. Non-compliance can lead to significant rework and legal repercussions.

- Inspection Facilitation

Permits enable building inspectors to conduct on-site evaluations at various stages of construction. These inspections ensure that work is performed according to approved plans and that materials used meet minimum standards. A common inspection involves verifying the correct installation of electrical wiring before drywall is installed. Neglecting these inspections can result in concealed defects and potential hazards.

- Property Value and Insurance Implications

Properly permitted improvements enhance the value of a property and ensure appropriate insurance coverage. Unpermitted alterations may not be recognized by insurance companies, potentially leading to claim denials in the event of damage. For instance, a finished lower level without permits might be considered an uninsurable space. This ultimately impacts the homeowner’s financial security.

- Liability Mitigation

Obtaining permits minimizes the homeowner’s liability in the event of accidents or injuries related to the completed lower level. Permitting demonstrates due diligence in ensuring a safe and compliant living space. Failure to secure necessary permits can expose the homeowner to legal action should an incident occur due to substandard construction. This illustrates the protective aspect of the regulatory process.

The facets detailed above underscore the multifaceted importance of permitting within the scope of completing an unfinished lower level. Adhering to this regulatory step contributes to a safe, compliant, and valuable addition to the residence. Failure to secure the proper documentation can have serious consequences.

3. Moisture Mitigation

Moisture mitigation represents a critical and often overlooked component in the sequence of actions required to complete an unfinished lower level. Its significance lies in preventing structural damage, promoting healthy indoor air quality, and ensuring the longevity of finished surfaces. Neglecting this aspect can lead to costly remediation efforts and compromise the habitability of the space.

- Source Identification and Remediation

Pinpointing and addressing the source of moisture intrusion is the first step in effective mitigation. This may involve identifying cracks in the foundation, inadequate drainage systems, or condensation issues. For example, hydrostatic pressure can force water through porous concrete, requiring the application of a waterproof sealant or the installation of a sump pump. Failure to address these sources allows moisture to continue permeating the structure, undermining subsequent completion efforts.

- Vapor Barrier Installation

A vapor barrier restricts the diffusion of water vapor through walls and floors, preventing condensation within the building envelope. Typically, a polyethylene sheet or specialized coating is applied to the warm side of the insulation. In humid climates, proper vapor barrier selection and installation are paramount to prevent moisture accumulation, which can lead to mold growth and structural decay. Improper installation can trap moisture, exacerbating the problem.

- Dehumidification Systems

Mechanical dehumidification systems actively remove moisture from the air, maintaining a relative humidity level that inhibits mold growth and reduces condensation. These systems are particularly beneficial in lower levels with high humidity levels, even after addressing primary moisture sources. Regular maintenance and proper sizing of the dehumidifier are crucial for optimal performance. Neglecting this step can result in persistent dampness and associated health concerns.

- Proper Ventilation Techniques

Adequate ventilation facilitates the removal of moist air and the introduction of fresh, dry air. This can be achieved through natural ventilation, such as operable windows, or mechanical ventilation systems, such as exhaust fans. Insufficient ventilation contributes to moisture buildup, particularly in areas prone to humidity, such as bathrooms and laundry rooms. Proper ventilation is essential to complement other mitigation efforts and maintain a healthy indoor environment.

Effective moisture mitigation is not a singular action but an integrated approach involving source control, barrier implementation, active dehumidification, and proper ventilation. Integrating these strategies within the completion process is essential for creating a durable, healthy, and comfortable living space. Ignoring this step often leads to significant problems.

4. Framing and Structure

The framing and structural phase is a pivotal stage in the sequence of completing an unfinished lower level. It establishes the foundational skeleton that defines the spatial layout, ensures structural integrity, and provides a framework for subsequent mechanical and finishing installations.

- Wall Erection and Load Distribution

Construction of walls using lumber or steel studs is essential for partitioning the space and bearing loads from upper levels. Proper framing techniques, including accurate stud spacing and secure connections, are critical for structural stability. For instance, bearing walls must be adequately supported by footings and transfer loads to the foundation. Improper wall construction can lead to structural failure and safety hazards.

- Egress and Window Framing

Incorporating egress windows and doors is crucial for safety and code compliance. Proper framing ensures that these openings are structurally sound and meet minimum size requirements for emergency escape. An egress window typically requires a specified net clear opening and a window well for access. Deficiencies in egress framing can impede escape in the event of a fire or other emergency.

- Mechanical Chase Creation

Framing provides pathways and enclosures for routing plumbing, electrical, and HVAC systems. These mechanical chases must be strategically planned to minimize obstructions and allow for future access. For example, framing around ductwork requires careful consideration of airflow and insulation requirements. Inadequate planning of mechanical chases can result in inefficient system performance and costly modifications.

- Ceiling and Soffit Framing

Framing is essential for creating a level ceiling and concealing ductwork, pipes, and wiring within soffits. Proper ceiling framing techniques, including the use of furring strips and suspension systems, ensure a smooth and even surface for finishing materials. Soffits require careful framing to accommodate mechanical systems while maintaining adequate headroom. Deficiencies in ceiling and soffit framing can detract from the aesthetic appeal and functionality of the space.

These framed components directly impact the safety, usability, and aesthetic qualities of the completed lower level. Careful attention to detail during this phase is essential for a successful project. Each element described forms a cornerstone of the structural integrity.

5. Electrical and Plumbing

The integration of electrical and plumbing systems is a critical, non-negotiable step in the completion of a lower level. These utilities are fundamental to rendering the space habitable and functional, impacting safety, convenience, and code compliance. Improper installation or omission of these systems can lead to significant hazards and render the area unusable or unsellable. For instance, the absence of correctly grounded electrical outlets can pose a severe electrocution risk, while inadequate plumbing can result in water damage and sanitation issues.

Electrical and plumbing work within the context of the completion process typically involves running new circuits and lines to accommodate lighting, outlets, appliances, and fixtures. This demands adherence to strict building codes, necessitating the employment of licensed professionals to ensure safe and compliant installations. A common example is the installation of ground fault circuit interrupters (GFCIs) in wet areas, such as bathrooms or near laundry facilities, to prevent electrical shocks. Similarly, proper drainage slope and venting are essential to prevent sewer gas buildup and clogs in plumbing systems. Consider a scenario where a homeowner fails to properly vent a new toilet; the resulting sewer gas infiltration would render the renovated space uninhabitable. The sequence of installation is also critical, typically occurring after framing and before insulation and drywall.

In conclusion, the successful incorporation of electrical and plumbing systems represents a crucial element in finishing a basement. Their correct and code-compliant implementation directly influences the space’s safety, functionality, and overall value. Overlooking these systems or attempting to circumvent proper installation procedures introduces considerable risks and potential legal liabilities, underscoring the necessity for professional execution and meticulous attention to detail throughout this phase. The challenges lie in navigating complex code requirements and ensuring seamless integration with existing home systems, highlighting the need for expertise and careful planning.

6. Insulation

Insulation plays a critical role in the sequence of actions to complete a lower level, directly impacting energy efficiency, comfort, and moisture control. Properly installed insulation minimizes heat transfer, maintaining consistent temperatures and reducing heating and cooling costs. For instance, uninsulated walls in a below-grade environment can lead to significant heat loss during winter and heat gain during summer, resulting in uncomfortable living conditions and increased utility bills. Inadequate insulation also contributes to condensation, fostering mold growth and structural decay. The selection of appropriate insulation materials, such as rigid foam or fiberglass batts with a vapor barrier, is paramount for optimal performance in the specific environment.

The positioning of insulation within the wall assembly is crucial to its effectiveness. In colder climates, insulation should be installed with a vapor barrier facing the warm interior to prevent moisture from penetrating the wall cavity. In warmer climates, a vapor retarder may be more appropriate to allow some moisture diffusion. Moreover, insulation should be continuous and free of gaps to prevent thermal bridging, which can significantly reduce its overall performance. Consider the example of improperly installed insulation around electrical outlets or pipes, creating thermal bridges that allow heat to escape, negating the benefits of the insulation in surrounding areas. The R-value, a measure of thermal resistance, should be carefully considered based on climate zone and local building codes to achieve optimal energy efficiency.

In summary, insulation is an indispensable element in finishing a basement, contributing to energy savings, comfort, and long-term structural integrity. Its proper selection, installation, and maintenance are essential to achieving these benefits. Neglecting this aspect can lead to increased energy consumption, moisture problems, and compromised living conditions. The correlation between effective insulation and a successful conversion project underscores its importance in the overall framework of the endeavor. Ignoring insulation, or doing so incorrectly, creates a domino effect of negative consequences for all subsequent work.

7. Finishing

The concluding stage, often referred to as “Finishing,” represents the culmination of all prior “steps to finish a basement.” It encompasses a series of tasks that transform a structurally sound, mechanically functional space into a habitable and aesthetically pleasing environment. The quality and execution of these final tasks significantly impact the overall value and usability of the converted area.

- Drywall Installation and Preparation

This involves affixing drywall sheets to the framed walls and ceilings, followed by taping, mudding, and sanding to create a smooth, paintable surface. For example, properly executed drywall work ensures seamless transitions between walls and ceilings, eliminating visible imperfections. Poor drywall finishing detracts from the overall aesthetic appeal and can necessitate costly repairs.

- Painting and Trim Work

Painting provides the aesthetic color and protective coating for walls and ceilings. Trim work, including baseboards, door casings, and window moldings, adds architectural detail and covers seams. Selecting appropriate paint types and trim styles complements the overall design and enhances the perceived value of the space. Substandard painting or poorly fitted trim diminishes the visual appeal and can compromise the durability of the finishes.

- Flooring Installation

This involves laying down the chosen flooring material, such as carpet, tile, laminate, or hardwood. Proper subfloor preparation and precise installation are essential for a level, durable, and aesthetically pleasing floor surface. For example, a correctly installed tile floor provides a waterproof and easily maintainable surface for a bathroom. Incorrectly laid flooring can result in uneven surfaces, squeaking, and premature wear.

- Fixture and Appliance Installation

The final phase includes installing light fixtures, outlets, switches, plumbing fixtures (sinks, toilets, showers), and appliances (if applicable). Correct installation ensures that these components function safely and efficiently. For instance, installing energy-efficient LED lighting reduces energy consumption and prolongs bulb life. Improperly installed fixtures can create safety hazards and necessitate costly repairs.

These interconnected facets of “Finishing” directly determine the ultimate success of the “steps to finish a basement.” The culmination of quality materials and skilled craftsmanship during this concluding stage enhances the property’s value, creates a comfortable living environment, and ensures the long-term durability of the transformed area. Neglecting or compromising these final details can undermine the investment made in the preceding stages.

Frequently Asked Questions Regarding Lower Level Completion

This section addresses common inquiries and misconceptions surrounding the process of transforming an unfinished lower level into a habitable space.

Question 1: Is it permissible to complete a lower level without obtaining building permits?

Completing a lower level without securing the necessary permits is generally not advisable and may be illegal. Permits ensure compliance with building codes, safeguarding occupants and mitigating potential structural issues. Failure to obtain permits can result in fines, mandated remediation, and difficulties with future property transactions.

Question 2: How is moisture effectively managed in below-grade environments?

Effective moisture management involves identifying and rectifying sources of water intrusion, installing a vapor barrier, employing dehumidification systems, and ensuring adequate ventilation. These measures collectively prevent moisture buildup, which can lead to mold growth, structural damage, and unhealthy indoor air quality.

Question 3: What are the primary considerations when framing a lower level?

Framing considerations include proper wall erection and load distribution, incorporation of egress windows and doors, creation of mechanical chases for utilities, and appropriate ceiling and soffit construction. Accurate framing ensures structural integrity, safety, and functionality of the completed space.

Question 4: Who is qualified to perform electrical and plumbing work in a lower level?

Electrical and plumbing work should be performed by licensed professionals who are knowledgeable about local codes and regulations. This ensures safe and compliant installations, minimizing the risk of electrical shock, water damage, and code violations.

Question 5: What type of insulation is best suited for below-grade applications?

Insulation materials suitable for below-grade applications include rigid foam, fiberglass batts with a vapor barrier, and spray foam. The choice of insulation depends on factors such as climate, budget, and desired R-value. Proper insulation is essential for energy efficiency, comfort, and moisture control.

Question 6: What are the key steps in finishing a lower level’s surfaces?

Finishing steps include drywall installation and preparation, painting and trim work, flooring installation, and fixture and appliance installation. These tasks transform a structurally sound space into an aesthetically pleasing and functional living environment.

In conclusion, successfully completing a lower level requires careful planning, adherence to codes, and meticulous execution of each phase.

The subsequent section will explore common pitfalls encountered during lower-level completion and strategies for their prevention.

Steps to Finish a Basement

The preceding sections have detailed the sequential phases involved in completing an unfinished lower level, encompassing planning, permitting, moisture mitigation, framing, mechanical systems, insulation, and finishing. Each phase demands meticulous attention to detail, adherence to building codes, and the use of appropriate materials to ensure a safe, functional, and aesthetically pleasing living space. The overarching goal is to transform an underutilized area into a valuable asset, enhancing property value and expanding living space.

Successful execution of these “steps to finish a basement” requires a proactive approach, prioritizing thorough planning and the engagement of qualified professionals. Proper execution guarantees a lasting enhancement to the residence, increasing both its market value and the quality of life for its inhabitants. Therefore, a commitment to quality and meticulousness is paramount to the successful completion of this significant undertaking.