The protective and decorative coating applied to the internal hinged or sliding barriers within a structure significantly impacts both their longevity and aesthetic appeal. This coating, available in a variety of sheens and formulations, serves to shield the underlying material from moisture, impacts, and everyday wear, while simultaneously contributing to the overall design of the space. For example, a high-gloss enamel provides a durable and easily cleanable surface ideal for high-traffic areas, while a matte latex offers a softer, more subtle visual texture.

Selecting the appropriate type offers considerable advantages, extending the lifespan of the barriers by preventing warping, cracking, and decay. Furthermore, it enhances the visual coherence of the interior, allowing for the coordination of colors, textures, and light reflectivity to achieve a desired ambiance. Historically, choices were limited, primarily focusing on oil-based products; however, advancements in chemistry have broadened the spectrum to include water-based options with improved performance characteristics and reduced environmental impact.

Understanding the different types, their application methods, and their suitability for various environments is crucial for achieving optimal results. Subsequent sections will delve into the specific categories available, focusing on the characteristics of each and providing guidance on selection and application techniques. This includes examining preparation steps, application tools, and considerations for specific door materials, such as wood, metal, and composite.

Application Strategies for Interior Door Coatings

Achieving a professional and durable result requires careful consideration of several factors. The following guidelines offer insights into best practices for achieving optimal appearance and longevity.

Tip 1: Surface Preparation is Paramount: Thoroughly clean and sand the surface to remove imperfections and ensure proper adhesion. Existing coatings must be evaluated for compatibility with the new finish. A properly prepared substrate significantly extends the lifespan of the coating system.

Tip 2: Primer Selection Matters: Choose a primer specifically formulated for the substrate material. Primers enhance adhesion, block stains, and provide a uniform base for the topcoat. Failure to prime adequately can result in peeling, blistering, or uneven color absorption.

Tip 3: Employ Multiple Thin Coats: Apply several thin coats rather than a single thick coat. This technique minimizes runs, drips, and sagging, resulting in a smoother, more even finish. Allow each coat to dry completely before applying the subsequent layer.

Tip 4: Use Quality Application Tools: Invest in high-quality brushes, rollers, or spray equipment. The tool used directly impacts the final appearance. For example, a fine-bristle brush is preferred for achieving a smooth, even application of enamel coatings.

Tip 5: Maintain Consistent Environmental Conditions: Temperature and humidity levels can significantly affect the drying and curing process. Ensure adequate ventilation and maintain the recommended temperature range specified by the coating manufacturer.

Tip 6: Sand Lightly Between Coats: Lightly sand between coats with fine-grit sandpaper to remove imperfections and create a smooth surface for the next layer. This process enhances the overall smoothness and appearance of the final coating.

Tip 7: Allow Adequate Drying Time: Adhere strictly to the manufacturer’s recommended drying times. Premature handling or recoating can lead to defects and compromise the integrity of the coating.

Consistent application of these strategies yields a durable and aesthetically pleasing outcome, enhancing both the appearance and longevity of the interior barrier. Proper execution minimizes the need for future repairs or recoating.

The subsequent discussion will explore specific coating types and their respective application requirements, providing a more detailed examination of best practices for each material.

1. Durability

Durability, in the context of coatings for interior doors, refers to the capacity of the applied film to withstand physical wear, chemical exposure, and environmental stressors over an extended period. The inherent ability of the surface to resist degradation directly impacts the longevity and aesthetic appeal of the door, thereby influencing maintenance schedules and overall lifecycle costs.

- Abrasion Resistance

Abrasion resistance denotes the coating’s ability to withstand scratching, scuffing, and general wear resulting from regular contact. For instance, doors in high-traffic areas such as hallways or entryways are subject to frequent contact with people, objects, and cleaning implements. A coating with poor abrasion resistance will quickly exhibit scratches and a dulled appearance, necessitating premature refinishing. Choosing a coating formulated with robust polymers enhances its resistance to physical damage.

- Impact Resistance

Impact resistance refers to the coating’s ability to absorb sudden shocks without chipping, cracking, or delaminating. Doors are susceptible to impacts from moving furniture, accidental collisions, and other unforeseen events. An insufficient impact resistance will lead to localized damage, requiring spot repairs or complete recoating. The incorporation of flexible resins and additives improves the coating’s capacity to withstand physical impacts without compromising its integrity.

- Chemical Resistance

Chemical resistance signifies the coating’s ability to withstand exposure to household cleaning agents, solvents, and other chemicals without discoloration, softening, or degradation. Doors in kitchens and bathrooms are frequently exposed to cleaning products. A coating lacking sufficient chemical resistance will exhibit staining, blistering, or a compromised finish upon contact with these substances, impacting both its appearance and protective function. Formulations incorporating crosslinking polymers provide enhanced resistance to chemical attack.

- Moisture Resistance

Moisture resistance describes the coating’s ability to repel water and prevent moisture penetration into the underlying substrate. Doors in bathrooms, laundry rooms, and other humid environments are vulnerable to moisture damage, which can lead to warping, swelling, and the growth of mold or mildew. A coating with inadequate moisture resistance will compromise the structural integrity of the door and promote microbial growth. Utilizing coatings with low permeability and inherent water-repellent properties mitigates the risk of moisture-related issues.

The foregoing facets collectively determine the long-term performance of the applied film. The selection of a product exhibiting superior abrasion, impact, chemical, and moisture resistance ensures that the interior doors maintain their aesthetic appeal and structural integrity, minimizing the need for frequent maintenance and replacement.

2. Aesthetics

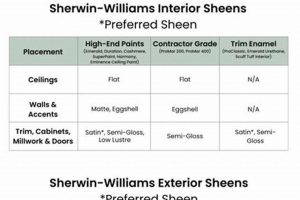

The aesthetic contribution of a coating applied to interior doors extends beyond mere color selection; it profoundly influences the perceived character and ambiance of the surrounding space. The finish acts as a visual element, harmonizing with or contrasting against wall colors, flooring materials, and decorative accents. A carefully chosen coating complements architectural styles, enhancing traditional, contemporary, or eclectic design schemes. Conversely, an incongruous selection can detract from the overall visual appeal, creating discord within the interior environment. For example, a high-gloss coating on a heavily ornamented door in a rustic setting might appear out of place, whereas a matte finish would better integrate with the established aesthetic. The surface’s reflective properties, sheen level, and texture collectively shape the interplay of light and shadow, impacting the perceived depth and dimension of the door itself and the adjacent area.

Consideration must also be given to the visual consistency across all interior doors within a given space or dwelling. While subtle variations may be acceptable, a cohesive aesthetic creates a sense of order and intention. Employing different coatings in distinct rooms can effectively demarcate functional zones, provided that these transitions are thoughtfully executed. Furthermore, the coating selection influences the perceived quality and craftsmanship of the door. A flawlessly applied, durable finish conveys a sense of meticulous attention to detail, enhancing the overall impression of the interior. Scratches, blemishes, or uneven application, conversely, diminish the perceived value of both the door and the surrounding environment. The ability to withstand the effects of light and time, resisting fading or discoloration, is a critical factor in maintaining the long-term aesthetic integrity of the coating. Examples includes the doors in the living room and bed room being different.

In summary, the aesthetic dimension of a coating for interior doors is a critical component of interior design, influencing visual harmony, perceived quality, and the overall atmosphere of a space. The challenge lies in balancing aesthetic preferences with functional requirements, selecting coatings that not only complement the design scheme but also provide long-term durability and ease of maintenance. The coating must integrate cohesively with all elements and must create an aesthetic cohesion with the room’s style and visual design.

3. Application

The application process directly determines the ultimate success of any coating system for interior doors. The selection of a superior coating formulation is rendered irrelevant if the application is flawed, resulting in premature failure and diminished aesthetic appeal. Proper surface preparation, for example, is a foundational element. Failure to adequately clean, sand, and prime the door surface will inevitably lead to adhesion issues, resulting in peeling, blistering, or cracking. The technique employed brushing, rolling, or spraying also profoundly influences the final outcome. Incorrect use of any of these methods can lead to uneven coverage, brush marks, or runs, compromising both the visual quality and the protective function of the coating. The environmental conditions during application, such as temperature and humidity, further impact the drying and curing process. Deviations from recommended ranges can result in defects in the finish, potentially shortening its lifespan.

A practical example illustrates the critical relationship between application and the integrity of the final finish. Consider a scenario in which a high-quality, moisture-resistant enamel is selected for a bathroom door. Despite the inherent protective properties of the coating, improper application such as failing to thoroughly seal all edges and corners will create vulnerabilities for moisture intrusion. Over time, this can lead to swelling of the door, peeling of the finish, and ultimately, the development of mold and mildew. Conversely, meticulous attention to detail during application, including proper edge sealing and adherence to recommended drying times, will maximize the coating’s protective capabilities, ensuring long-term durability and preventing moisture-related damage. The selection of appropriate application tools is also critical. Using an unsuitable brush or roller can introduce air bubbles, leave undesirable textures, or result in uneven coverage, detracting from the final appearance. The skill and experience of the applicator are, therefore, integral to achieving optimal results.

In summation, the application of a coating to interior doors is not merely a superficial step; it is a critical determinant of the coating’s performance and longevity. Understanding the nuances of surface preparation, application techniques, environmental factors, and tool selection is paramount for achieving a durable, aesthetically pleasing finish. Neglecting these aspects, even with the selection of a premium coating, will invariably lead to unsatisfactory results and premature failure. The challenges associated with application underscore the importance of proper training, meticulous execution, and adherence to manufacturer’s recommendations.

4. Material Compatibility

The selection of a coating for interior doors is significantly influenced by the compatibility between the coating formulation and the underlying door substrate. The substrate’s inherent properties dictate the coating’s adhesion, durability, and long-term performance. A mismatch can result in premature failure, aesthetic defects, and compromised protection against environmental factors.

- Wood Porosity and Grain

Wood, a common door material, exhibits varying degrees of porosity and grain patterns. Softwoods, like pine, tend to be more porous than hardwoods, such as oak or maple. This porosity affects the rate of coating absorption and the number of coats required to achieve uniform coverage. Highly porous woods necessitate the use of primers or sealers to prevent excessive absorption and ensure proper adhesion. The grain pattern also influences the application technique, as coatings may require specific brushing or spraying methods to achieve a smooth, even finish. Improper preparation or coating selection can lead to uneven color distribution, raised grain, or adhesion failure.

- Metal Surface Oxidation and Pre-treatment

Metal doors, often composed of steel or aluminum, present unique challenges related to surface oxidation. Steel is susceptible to rust, while aluminum can develop a layer of oxidation that inhibits coating adhesion. Pre-treatment processes, such as cleaning, etching, or applying a rust-inhibiting primer, are essential for ensuring a durable coating. Failure to address surface oxidation can result in peeling, blistering, or corrosion beneath the coating. The choice of coating should also consider the specific metal alloy used, as certain formulations may react adversely with specific metals, leading to discoloration or accelerated degradation.

- Composite Material Composition and Adhesion Promoters

Composite doors, constructed from materials like fiberglass or engineered wood, offer a blend of durability and design flexibility. However, their unique composition necessitates careful consideration of coating compatibility. Many composite materials exhibit low surface energy, which can hinder coating adhesion. Adhesion promoters, such as specialized primers or surface treatments, are often required to enhance the bond between the coating and the substrate. The choice of coating should also account for the thermal expansion and contraction properties of the composite material, as significant differences can lead to cracking or delamination over time.

- Previously Coated Surfaces and Intercoat Adhesion

When recoating existing doors, the compatibility between the new coating and the existing finish is critical. Incompatible coatings can result in intercoat adhesion failure, leading to peeling or cracking. Proper surface preparation, including sanding or chemical stripping, is often necessary to remove loose or failing coatings and create a suitable surface for the new finish. A compatibility test, involving applying a small sample of the new coating to an inconspicuous area, is recommended to assess adhesion and identify potential issues before full application.

These facets highlight the intricate relationship between substrate characteristics and the selection of an appropriate coating for interior doors. A comprehensive understanding of material properties and the corresponding coating requirements is essential for achieving a durable, aesthetically pleasing, and long-lasting finish. Consideration of these factors minimizes the risk of premature failure and ensures that the coating effectively protects and enhances the underlying door material.

5. Cost-Effectiveness

The cost-effectiveness of a paint finish for interior doors extends beyond the initial purchase price of the coating. It encompasses the long-term expenses associated with application, maintenance, and potential replacement. A seemingly inexpensive coating may prove more costly in the long run if it requires frequent reapplication due to poor durability or inadequate resistance to wear and tear. For example, a low-VOC latex product, while initially attractive due to its reduced environmental impact and lower cost, may necessitate more frequent touch-ups compared to a higher-quality alkyd enamel in high-traffic areas. The labor cost associated with reapplying the less durable coating can quickly offset any initial savings.

The selection of a suitable coating significantly impacts the overall lifecycle cost of interior doors. Durable coatings, while potentially more expensive upfront, offer greater resistance to scratches, stains, and moisture, reducing the need for frequent cleaning and repairs. Consider a scenario in which a commercial building utilizes a durable two-part epoxy coating on its interior doors. Although the initial investment is higher, the coating’s resistance to damage from carts, cleaning equipment, and daily use minimizes maintenance costs over the door’s lifespan. Conversely, a residential homeowner opting for a cheaper, less durable coating on interior doors may face expenses related to frequent cleaning, touch-up painting, or even premature door replacement due to damage or wear. Proper surface preparation, though often overlooked, contributes significantly to cost-effectiveness. Thorough sanding, priming, and cleaning of the door surface ensure optimal coating adhesion, prolonging the lifespan of the finish and minimizing the need for costly repairs or recoating.

In conclusion, a comprehensive assessment of cost-effectiveness in paint finishes for interior doors necessitates consideration of initial material costs, application expenses, maintenance requirements, and long-term durability. The selection of a coating should not solely be based on the lowest upfront price, but rather on a holistic evaluation of the product’s performance characteristics and its impact on the overall lifecycle cost of the interior doors. Challenges arise in accurately predicting long-term wear and tear; however, prioritizing durability and proper application techniques are crucial for maximizing cost-effectiveness. This understanding directly links to the broader theme of sustainable building practices and responsible resource management.

6. Environmental Impact

The selection of a paint finish for interior doors exerts a tangible influence on the environment, encompassing resource extraction, manufacturing processes, volatile organic compound (VOC) emissions, and end-of-life disposal. Traditional formulations, often relying on petroleum-based solvents and heavy metal pigments, contribute to air and water pollution during production and application. The release of VOCs, such as formaldehyde and xylene, into the indoor environment poses health risks to occupants, exacerbating respiratory ailments and contributing to the formation of ground-level ozone. The disposal of leftover paint and contaminated application materials further compounds the environmental burden, potentially contaminating soil and water resources. Conversely, the adoption of environmentally conscious alternatives, such as water-based acrylics and paints with reduced or zero VOC content, can mitigate these adverse effects. These formulations utilize renewable resources, minimize the release of harmful pollutants, and facilitate easier cleanup and disposal.

The growing awareness of environmental sustainability has spurred the development and adoption of eco-friendly coating technologies. Manufacturers are increasingly incorporating recycled materials, bio-based resins, and non-toxic pigments into their products. Independent certification programs, such as Green Seal and GREENGUARD, provide assurance that a paint finish meets stringent environmental standards. For instance, a hospital selecting a zero-VOC paint for its interior doors not only reduces the exposure of patients and staff to harmful chemicals but also contributes to a healthier indoor air quality, promoting healing and well-being. Similarly, a school adopting a low-VOC paint minimizes potential health risks for students and teachers, creating a more conducive learning environment. The lifecycle assessment of paint finishes also plays a critical role in evaluating their environmental impact. This comprehensive analysis considers the entire product lifecycle, from raw material extraction to disposal, identifying opportunities for reducing resource consumption, minimizing waste generation, and improving energy efficiency.

In conclusion, the environmental impact of paint finishes for interior doors is a multifaceted consideration encompassing air and water quality, resource depletion, and human health. The transition to environmentally conscious formulations, coupled with responsible application and disposal practices, is essential for mitigating these adverse effects. While challenges remain in balancing performance requirements with environmental concerns, the increasing availability of eco-friendly options and the growing awareness of sustainability are driving positive change. The proper selection and use of coating directly influences the ecological footprint of a building and aligns with broader efforts to promote a more sustainable built environment. A life cycle assessment is a very powerful tool for building a product with less environmental impact.

Frequently Asked Questions

This section addresses common inquiries regarding coatings for interior doors, providing concise and informative answers to assist in the selection and application process.

Question 1: What constitutes a “low-VOC” paint, and why is it beneficial?

Low-VOC, or low volatile organic compound, coatings contain a reduced amount of chemicals that evaporate into the air during and after application. These emissions contribute to indoor air pollution and can pose health risks. Opting for a low-VOC product minimizes these concerns, improving indoor air quality and promoting a healthier environment.

Question 2: Is priming necessary before applying a paint finish to interior doors?

Priming is generally recommended, particularly on bare wood or previously uncoated surfaces. A primer seals the substrate, promotes adhesion of the topcoat, and can block stains from bleeding through. This step contributes to a more uniform and durable finish.

Question 3: What type of brush is best suited for applying enamel coatings to interior doors?

A high-quality brush with fine, synthetic bristles is generally preferred for applying enamel coatings. These brushes provide a smooth, even application and minimize brush strokes, resulting in a professional-looking finish. Natural bristle brushes are suitable for some oil-based coatings, but are generally not recommended for water-based products.

Question 4: How can runs and drips be prevented during the application of paint to interior doors?

Runs and drips are typically caused by applying too much coating at once. Applying multiple thin coats, allowing each coat to dry thoroughly before applying the next, minimizes the risk of these imperfections. Maintaining a consistent application speed and avoiding excessive overlap also helps prevent runs and drips.

Question 5: What is the recommended drying time between coats of paint on interior doors?

Drying times vary depending on the specific coating formulation and environmental conditions. Adhering strictly to the manufacturer’s recommended drying times is crucial for ensuring proper film formation and preventing defects. Premature recoating can lead to adhesion problems, wrinkling, or other undesirable outcomes.

Question 6: How should leftover paint be stored to maintain its quality?

Leftover coatings should be stored in a tightly sealed container in a cool, dry location away from direct sunlight and extreme temperatures. Inverting the can briefly before storage can help create an airtight seal. Properly stored coatings can remain usable for several years, minimizing waste and reducing the need for frequent repurchases.

The key takeaways from these FAQs emphasize the importance of proper preparation, application techniques, and product selection in achieving a durable and aesthetically pleasing finish on interior doors.

The subsequent section will delve into case studies, providing real-world examples of successful coating applications and highlighting best practices in various scenarios.

Conclusion

The preceding discussion has comprehensively explored the multifaceted aspects of paint finish for interior doors. Key considerations include durability, aesthetics, application techniques, material compatibility, cost-effectiveness, and environmental impact. A thorough understanding of these elements is paramount for achieving optimal results and ensuring the long-term performance of the selected coating system. The proper selection and application directly influence the appearance, longevity, and overall value of interior doors within a building.

In light of the information presented, a diligent approach to coating selection and application is strongly advised. Prioritizing informed decision-making based on project-specific requirements and a comprehensive understanding of available coating options will contribute to a more sustainable, aesthetically pleasing, and cost-effective outcome. The continued advancement of coating technologies promises further improvements in durability, environmental performance, and ease of application, warranting ongoing attention to industry innovations.