A portable, battery-powered tool designed for driving finish nails into wood surfaces defines the category. It provides a method for completing trim work, cabinetry installation, and other fine woodworking tasks without the need for air compressors or hoses. This type of tool utilizes a rechargeable battery pack to power a mechanism that rapidly inserts nails, typically 15 or 16 gauge, into the intended material.

The advent of such equipment offers advantages in terms of job site mobility and reduced setup time. Eliminating pneumatic components streamlines the work process, allowing for quicker transitions between tasks and enhancing overall efficiency. The compact nature of these devices also facilitates operation in confined spaces where traditional nail guns might prove cumbersome. This technology is increasingly prevalent in professional carpentry and DIY projects due to its convenience and performance.

The following sections will delve into specific models available, discuss factors to consider when selecting the appropriate tool, and address common maintenance practices to ensure optimal performance and longevity.

Operation and Maintenance Recommendations

The following recommendations are provided to ensure the reliable and safe operation of the equipment, and to extend its service life.

Tip 1: Battery Management: Maintain optimal battery performance through proper charging and storage procedures. Always fully charge batteries before initial use and avoid leaving batteries on the charger for extended periods after they are fully charged. Store batteries in a cool, dry environment to prevent degradation.

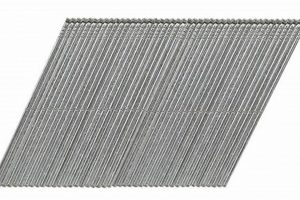

Tip 2: Nail Selection: Use only collated nails that are specifically designed and compatible with the equipment. Employing incorrect nail types can lead to jams, misfires, and potential damage to the tool.

Tip 3: Depth Adjustment: Adjust the nail depth setting to match the material being fastened. Insufficient depth results in protruding nails, while excessive depth can damage the work surface. Test the setting on scrap material before proceeding with the final application.

Tip 4: Consistent Maintenance: Regularly inspect the equipment for signs of wear and tear, including the driver blade, contact trip, and magazine. Clean the tool regularly to remove dust, debris, and nail fragments that can impede performance.

Tip 5: Proper Storage: When not in use, store the equipment in a secure, dry location, preferably in its original case. This prevents accidental damage and exposure to environmental elements that can compromise its functionality.

Tip 6: Addressing Jams: In the event of a nail jam, immediately disconnect the battery pack before attempting to clear the obstruction. Use the manufacturer-recommended procedure to remove the jammed nails and inspect the nail feed mechanism for any damage.

Adhering to these operational and maintenance guidelines maximizes the performance and extends the lifespan of the equipment, ensuring consistent and reliable operation throughout its service life.

The concluding section will review specific use cases and offer recommendations for selecting the most appropriate model based on project requirements.

1. Gauge

Gauge, in the context of a cordless finishing nailer, specifically defines the thickness of the nails that the tool is designed to drive. This is a critical specification directly impacting the tool’s application and the types of materials it can effectively fasten. A higher gauge number indicates a thinner nail. For instance, a 16-gauge nail is thicker and stronger than an 18-gauge nail. The chosen gauge must correspond to the intended use; selecting an incompatible gauge will result in tool malfunction or inadequate fastening.

The gauge dictates the holding power and visibility of the nail head. Thicker nails (lower gauge) offer increased holding power, suitable for more demanding applications such as securing thicker trim or assembling cabinet frames. However, these nails leave a more prominent hole, requiring more filling and finishing work. Thinner nails (higher gauge) leave a less noticeable mark, making them ideal for delicate trim work where aesthetics are paramount. The tool’s design is specifically engineered to handle a precise range of nail gauges, ensuring consistent and reliable driving performance. An example is a tool designed for 16-gauge nails cannot effectively utilize 15-gauge nails.

Therefore, understanding the gauge compatibility of the cordless finishing nailer is essential for successful project completion. Selecting the correct gauge ensures optimal holding strength, minimizes surface damage, and avoids potential tool damage from attempting to use incompatible fasteners. Neglecting this specification leads to compromised structural integrity, increased finishing work, or equipment failure. The selection of gauge should align with project requirements and material characteristics.

2. Battery Voltage

Battery voltage is a critical specification directly influencing the performance and capabilities of any cordless finishing nailer. It dictates the amount of power available to drive nails, affecting driving speed, depth consistency, and overall tool efficiency. Higher voltage generally corresponds to increased power, enabling the tool to handle denser materials and longer nails more effectively.

- Driving Power and Nail Depth

Higher battery voltage provides greater force to drive nails into various materials. Insufficient voltage may result in nails not being fully seated, especially in hardwoods. A 20V system, for example, will typically deliver more driving force than a 12V system, translating to more consistent and flush nail placement across a wider range of applications.

- Runtime and Efficiency

While voltage indicates power, amp-hours (Ah) determine the runtime of the battery. Higher voltage systems often work more efficiently, potentially requiring less amp-hour capacity to deliver comparable performance to lower voltage systems. However, balancing voltage with amp-hours is crucial to achieve both adequate power and sufficient runtime for the intended tasks.

- Tool Weight and Ergonomics

Battery voltage can indirectly affect the tool’s overall weight and size. Higher voltage systems might require larger battery packs, potentially increasing the tool’s weight and impacting ergonomics. Manufacturers must carefully balance power output with user comfort to provide a tool that is both powerful and easy to handle for extended periods.

- Compatibility within a System

Battery voltage is often tied to a specific tool ecosystem. A DeWalt 20V cordless finishing nailer, for instance, will typically utilize DeWalt’s 20V MAX battery platform, allowing users to interchange batteries between various tools within that system. This compatibility is a significant factor for professionals already invested in a particular brand’s battery system.

The battery voltage of a cordless finishing nailer is not an isolated specification. It is intricately linked to other factors, such as motor design, nail gauge capacity, and overall tool construction. Selecting the appropriate voltage requires careful consideration of the types of projects, materials, and expected usage patterns to ensure optimal performance and user satisfaction.

3. Nail Length

The permissible nail length range represents a critical specification for any cordless finishing nailer. This parameter directly dictates the types of applications the tool can perform and the thickness of materials it can effectively join. A DeWalt cordless finishing nailer, like other similar tools, features a defined range of nail lengths it is engineered to accommodate. Exceeding these specified limits introduces the risk of tool damage, fastener jams, or compromised joint integrity. For example, a tool designed for nail lengths between 1-1/4 inches and 2-1/2 inches cannot reliably drive 3-inch nails, potentially leading to driver blade damage or nail bending. Conversely, attempting to use nails shorter than the minimum specified length can result in misfires or inconsistent nail placement.

The relationship between nail length and material thickness is paramount. The selected nail length should penetrate sufficiently into both workpieces to ensure a secure and durable connection. A general guideline suggests the nail should penetrate at least two-thirds of its length into the receiving material. For instance, when attaching 3/4-inch trim to a solid wood frame, a nail length of at least 1-1/4 inches is typically required. Using a shorter nail, such as a 1-inch nail, may not provide adequate holding power, resulting in the trim detaching over time. Conversely, using a nail that is excessively long may protrude through the back of the material, creating an undesirable aesthetic and potential safety hazard. The DeWalt cordless finishing nailers adjustable depth setting helps optimize nail placement based on the selected nail length and material density.

In conclusion, proper consideration of nail length is essential for maximizing the performance and longevity of the DeWalt cordless finishing nailer. Selecting the appropriate nail length, within the tool’s specified range, ensures secure fastening, minimizes the risk of tool damage, and contributes to a professional and durable finish. Ignoring this critical specification compromises the quality of the work and can lead to costly repairs or rework.

4. Sequential/Contact Actuation

The presence of selectable actuation modes constitutes a defining feature in contemporary cordless finishing nailers, significantly influencing operational safety and speed. Specifically, DeWalt cordless finishing nailers incorporate both sequential and contact actuation options to cater to diverse application requirements. Sequential actuation necessitates depressing the safety contact tip against the workpiece, followed by separate trigger pull for each nail fired, reducing the risk of accidental discharge. Contact actuation, conversely, allows for rapid firing by holding the trigger and bumping the contact tip against the work surface. Understanding the implications of each mode is critical for maximizing efficiency and minimizing potential hazards on any job site.

The selection of actuation mode directly impacts work efficiency and precision. Sequential actuation is commonly employed for tasks demanding high accuracy and controlled nail placement, such as intricate trim work or cabinet assembly. By requiring a deliberate, step-by-step process, it reduces the likelihood of misfires and ensures consistent nail depth. Conversely, contact actuation is favored for high-volume applications, such as flooring or sheathing, where speed is paramount. While offering faster nail delivery, contact actuation necessitates a higher degree of operator skill to maintain accuracy and avoid surface damage. The ability to switch between these modes in DeWalt cordless finishing nailers enables users to tailor tool behavior to specific task requirements, promoting adaptability and overall productivity.

The availability of both actuation modes in DeWalt cordless finishing nailers provides a significant advantage to professional users and DIY enthusiasts. By understanding the operational characteristics of each mode and selecting the appropriate setting for the task at hand, operators can enhance their work quality, improve their efficiency, and mitigate potential safety risks. The flexibility afforded by selectable actuation underscores the importance of considering this feature when evaluating the suitability of a cordless finishing nailer for a particular application.

5. Brushless Motor

The integration of a brushless motor within a DeWalt cordless finishing nailer represents a significant advancement in tool technology, directly influencing performance, efficiency, and longevity. Traditional brushed motors utilize carbon brushes to conduct electricity to the motor armature, leading to friction, heat generation, and eventual wear. Conversely, brushless motors employ electronic control systems to energize the motor windings, eliminating the need for physical brushes. This design yields several tangible benefits for the operation of a DeWalt cordless finishing nailer. For example, the reduced friction translates to cooler operating temperatures, minimizing the risk of overheating during extended use and increasing the tool’s lifespan. Furthermore, the absence of brushes eliminates a common wear component, reducing the need for maintenance and extending the time between servicing. Real-world benefits include increased runtime per battery charge and more consistent power delivery throughout the battery’s discharge cycle, critical for demanding applications requiring sustained performance.

The enhanced efficiency of a brushless motor directly impacts the nailer’s ability to consistently drive nails to the desired depth, even when working with denser materials or at varying angles. This consistency reduces the likelihood of nail set errors and minimizes the need for manual adjustments or rework. Consider, for instance, a situation where a carpenter is installing trim around a doorway. With a brushed motor nailer, the driving force might diminish as the battery discharges, leading to inconsistent nail penetration. A brushless motor-equipped DeWalt nailer, however, maintains a more consistent driving force, ensuring that each nail is driven to the correct depth, resulting in a cleaner, more professional finish. This also translates to improved battery efficiency, allowing the user to complete more work with a single battery charge, reducing downtime and increasing productivity.

In summary, the implementation of a brushless motor in a DeWalt cordless finishing nailer represents a critical engineering decision that directly translates to enhanced performance, improved efficiency, and extended tool life. While initial acquisition costs may be slightly higher compared to brushed motor models, the long-term benefits, including reduced maintenance, increased runtime, and more consistent power delivery, make it a worthwhile investment for professional users and serious DIY enthusiasts. The practical implications of understanding this technology extend to making informed purchasing decisions and appreciating the technological advancements that contribute to improved tool performance and user experience.

6. Magazine Capacity

Magazine capacity, within the context of a DeWalt cordless finishing nailer, signifies the number of fasteners the tool can hold at a given time. This parameter directly influences the user’s workflow and overall efficiency. A higher magazine capacity reduces the frequency of reloading, thereby minimizing interruptions during prolonged work sessions. This characteristic is particularly relevant in applications where consistent, uninterrupted operation is paramount, such as installing extensive trim work or completing large-scale woodworking projects. The nailer’s magazine design typically accommodates collated strips of finish nails, and the specified capacity indicates the maximum number of nails that can be loaded before requiring replenishment. The capacity can range depending on the model and the gauge of the nails used.

The practical implications of magazine capacity extend to various project scenarios. Consider a carpenter tasked with installing baseboards throughout a multi-room residence. A finishing nailer with a limited magazine capacity, such as 50 nails, necessitates frequent reloading, potentially adding significant time to the overall task. Conversely, a nailer with a higher capacity, such as 100 or 120 nails, allows for extended periods of uninterrupted operation, leading to increased productivity. The difference in reloading frequency translates directly into time savings and reduced physical exertion for the user. Furthermore, a larger magazine capacity reduces the likelihood of running out of nails mid-run, which can disrupt the flow of work and compromise the quality of the finished product. For example, needing to reload mid trim install can cause you to nail in the wrong place or not as straight.

In conclusion, magazine capacity is a critical consideration when selecting a DeWalt cordless finishing nailer, directly impacting efficiency and workflow. The choice of magazine capacity should align with the anticipated scale and nature of the projects. While a smaller magazine may suffice for occasional, small-scale tasks, larger projects benefit significantly from a higher capacity, reducing downtime and enhancing overall productivity. The ability to minimize interruptions through increased magazine capacity contributes to a more streamlined and efficient workflow, ultimately resulting in time savings and improved project outcomes. This often contributes to safety by decreasing the amount of interruptions as well.

7. Depth Adjustment

Depth adjustment is an integral feature in DeWalt cordless finishing nailers, directly impacting the quality and consistency of fastening. This functionality allows users to regulate the driving depth of nails, ensuring flush or countersunk placement across varying material densities. Proper depth adjustment prevents both protruding nail heads, which require additional finishing work, and excessive penetration, which can damage the work surface. The mechanism is usually a dial or knob located near the nailer’s nose, offering incremental adjustments to the driving force.

- Material Density Compensation

Different wood species exhibit varying densities, requiring corresponding adjustments to the nail driving depth. Softwoods, such as pine, require less force compared to hardwoods like oak or maple. The depth adjustment feature on a DeWalt cordless finishing nailer enables users to compensate for these differences, ensuring consistent nail placement regardless of the material. For example, when transitioning from fastening pine trim to oak trim, adjusting the depth setting prevents nails from over-penetrating the softer pine and under-penetrating the denser oak.

- Nail Length Optimization

Depth adjustment also complements the selection of appropriate nail lengths. Fine-tuning the driving depth ensures that the nail penetrates sufficiently to provide adequate holding power without protruding through the backside of the material. For instance, when using shorter nails for delicate trim work, the depth can be adjusted to prevent the nail head from sinking too deeply into the wood, which can compromise the trim’s aesthetic appeal.

- Surface Finish Preservation

Controlling the nail driving depth is crucial for preserving the integrity of the work surface. Excessive penetration can cause unsightly dents or blemishes, particularly on pre-finished materials. The depth adjustment feature allows users to dial in the precise driving depth, minimizing the risk of surface damage and reducing the need for costly repairs or replacements. This is particularly important when working with expensive or fragile materials, such as veneered panels or delicate moldings.

- Consistent Results and Reduced Rework

The ability to fine-tune nail driving depth translates directly to consistent results and reduced rework. By ensuring that each nail is driven to the correct depth, the likelihood of protruding nail heads or damaged surfaces is minimized. This, in turn, reduces the need for additional filling, sanding, or patching, saving time and effort. Consistent nail placement also contributes to a more professional and aesthetically pleasing finished product. If a carpenter does not get the depth right, then their work and time has gone wasted.

The depth adjustment feature on a DeWalt cordless finishing nailer is an indispensable tool for achieving professional-quality results. By enabling precise control over nail driving depth, it empowers users to adapt to varying material densities, optimize nail length selection, preserve surface finishes, and ultimately, produce consistent and aesthetically pleasing finished products. Mastering the use of this feature is critical for maximizing the performance and versatility of the DeWalt cordless finishing nailer across a wide range of applications.

Frequently Asked Questions About DeWalt Cordless Finishing Nailers

The following section addresses common inquiries regarding the usage, maintenance, and capabilities of DeWalt cordless finishing nailers.

Question 1: What is the recommended procedure for clearing a nail jam in a DeWalt cordless finishing nailer?

Following a nail jam, the initial step involves disconnecting the battery pack. Subsequently, disengage the magazine and carefully extract any visible nail fragments. Consult the tool’s manual for specific instructions on accessing and clearing the nail firing chamber. Avoid using excessive force, which may damage internal components.

Question 2: How often should a DeWalt cordless finishing nailer be serviced?

Service intervals are dependent on usage frequency and environmental conditions. Under normal operating conditions, a professional inspection is recommended every 6 to 12 months. More frequent servicing may be necessary in dusty or high-demand environments. Periodic cleaning of the nail magazine and driver blade is also advised.

Question 3: Is it possible to adjust the driving force of a DeWalt cordless finishing nailer for different wood densities?

Yes, DeWalt cordless finishing nailers are equipped with depth adjustment mechanisms, typically in the form of a dial or knob. This allows for fine-tuning the driving force to accommodate varying wood densities, ensuring proper nail seating without damaging the workpiece.

Question 4: What is the expected battery runtime for a DeWalt 20V MAX cordless finishing nailer?

Battery runtime varies based on the battery’s amp-hour (Ah) rating, the density of the material being fastened, and the frequency of use. A 4.0Ah battery can typically drive several hundred nails on a single charge under normal operating conditions. Always consult the tool’s specifications for estimated runtime figures.

Question 5: Can a DeWalt cordless finishing nailer be used for structural framing applications?

DeWalt cordless finishing nailers are designed primarily for finish and trim applications. These tools are not suitable for structural framing, which requires larger gauge nails and greater driving force. Employ a framing nailer specifically designed for structural applications.

Question 6: What type of nails are compatible with a DeWalt 16-gauge cordless finishing nailer?

A DeWalt 16-gauge cordless finishing nailer requires 16-gauge finish nails collated at the appropriate angle for the specific model. Refer to the tool’s manual for detailed specifications regarding compatible nail types and lengths.

Proper understanding and adherence to these guidelines promotes optimal performance and longevity of the equipment.

The subsequent section will explore considerations for selecting the optimal DeWalt cordless finishing nailer based on specific project requirements.

Conclusion

This exploration of the Dewalt cordless finishing nailer has examined its operational principles, critical features, and maintenance requirements. Specifications such as gauge, battery voltage, nail length, actuation modes, motor type, magazine capacity, and depth adjustment have been analyzed to provide a comprehensive understanding of the tool’s capabilities and limitations. Frequently asked questions have been addressed to clarify common points of concern.

The discerning user is now equipped with the knowledge to select, operate, and maintain this equipment effectively. Continued adherence to best practices ensures optimal performance, extended tool life, and consistent, professional-quality results. The Dewalt cordless finishing nailer represents a valuable asset when correctly applied within its intended scope.