A material created from birch trees that has undergone a treatment process to enhance its appearance and durability. This treatment often involves sanding, staining, and the application of a protective topcoat, resulting in a smooth, aesthetically pleasing surface ready for use in various applications, from furniture construction to interior paneling. For example, cabinets constructed from this material showcase a refined look while offering resilience against daily wear and tear.

This type of treated lumber is valued for its light color, fine grain, and ability to accept a variety of finishes. Historically, birch has been utilized in woodworking for centuries, and the application of finishing techniques expands its usability and market appeal. The benefits include increased resistance to moisture, scratches, and UV damage, extending the lifespan of the product and reducing maintenance requirements. Its aesthetic versatility allows it to be incorporated into diverse design styles, from rustic to modern.

The subsequent sections will delve into specific applications within furniture manufacturing, explore optimal maintenance procedures to preserve its quality, and analyze the economic advantages of choosing it over alternative materials. This will provide a comprehensive understanding of its multifaceted value and practical considerations for its utilization.

Practical Considerations for Preserving Treated Birch Lumber

The following recommendations aim to optimize the longevity and aesthetic appeal of surfaces constructed from treated birch.

Tip 1: Regular Dusting: Consistent removal of surface dust prevents the accumulation of abrasive particles that can gradually dull the finish. A soft cloth or microfiber duster is recommended.

Tip 2: Immediate Spill Cleanup: Promptly address spills with a clean, absorbent cloth. Avoid allowing liquids to dwell on the surface, as prolonged exposure can compromise the protective coating.

Tip 3: Controlled Humidity: Maintain a stable humidity level in the environment where items made with the specified material are located. Excessive humidity can lead to warping or swelling, while overly dry conditions can cause cracking.

Tip 4: UV Radiation Mitigation: Minimize direct exposure to sunlight. Prolonged UV radiation can fade the finish and potentially damage the underlying wood. Consider using curtains or blinds in areas with significant sunlight exposure.

Tip 5: Avoid Abrasive Cleaners: Refrain from using harsh chemicals or abrasive cleaning products. These can scratch or dissolve the finish, diminishing its protective qualities and aesthetic value. Opt for pH-neutral cleaning solutions specifically designed for wood finishes.

Tip 6: Furniture Pads and Coasters: Employ furniture pads beneath objects placed on the surface to prevent scratches and indentations. Utilize coasters under beverages to avoid water rings and potential damage from heat.

Tip 7: Periodic Re-Finishing: Depending on the level of use and environmental conditions, consider re-applying a protective topcoat every few years to maintain its durability and appearance. This should be performed by a qualified professional.

Adhering to these recommendations will contribute significantly to preserving the integrity and visual appeal of treated birch surfaces, ensuring a lasting investment.

The following section will discuss the economic advantages of selecting this treated lumber over alternative materials in various applications.

1. Aesthetic Versatility

The aesthetic versatility inherent in surfaces crafted from treated birch stems from several core properties. Its light, consistent color provides a neutral base, allowing for a wide range of finishing options without clashing with the underlying wood tone. This characteristic enables the material to adapt to diverse design styles, from minimalist Scandinavian aesthetics to more ornate traditional settings. The fine, even grain pattern, while subtle, adds visual interest without overpowering other design elements. This inherent adaptability is a crucial component of its appeal, allowing it to function as a blank canvas for various decorative treatments.

For example, in modern interior design, treated birch is frequently employed in cabinetry and millwork, finished with light stains or clear sealants to emphasize its natural grain and maintain a clean, minimalist look. Conversely, in more traditional applications, it may be stained with darker tones and paired with ornate hardware to create a richer, more formal aesthetic. Its capacity to effectively accept paint also broadens its application in projects that require custom color matching or intricate detailing. Consider the use of painted cabinets in a variety of colors. Birch is paintable and offers a consistent finish. This showcases its ability to seamlessly integrate into spaces with diverse color palettes.

In summary, the aesthetic versatility of treated birch is not merely a superficial attribute but rather a fundamental characteristic arising from its physical properties. This adaptability contributes significantly to its widespread use across a spectrum of design styles and applications. A deeper understanding of this quality, and how it interacts with various finishing techniques, is essential for maximizing the potential of this material in any project. This helps to ensure a visually cohesive and aesthetically pleasing outcome.

2. Surface Durability

Surface durability, when considered in the context of birch lumber that has undergone finishing processes, refers to the ability of the resultant surface to resist damage from various forms of wear, including abrasion, impact, chemical exposure, and environmental factors. This attribute is paramount in determining the longevity and suitability of the material for a wide range of applications.

- Protective Coating Adhesion

The adhesion between the applied finish and the underlying birch substrate is a crucial determinant of surface durability. A well-bonded finish prevents chipping, peeling, and blistering, thereby maintaining a protective barrier against moisture and physical damage. The finishing process, including surface preparation and the type of adhesive utilized, directly influences the strength of this bond. Poor adhesion can lead to premature failure of the finish and expose the wood to environmental degradation.

- Abrasion Resistance

Abrasion resistance denotes the capacity of the finished surface to withstand scratching and scuffing caused by contact with abrasive materials. The choice of finish, particularly the type and quantity of topcoat applied, significantly impacts abrasion resistance. Polyurethane finishes, for instance, typically offer superior abrasion resistance compared to lacquer finishes. This property is especially relevant in high-traffic areas or applications where the surface is subject to frequent contact with potentially abrasive objects.

- Chemical Resistance

Chemical resistance refers to the ability of the finished surface to withstand exposure to various chemicals, including household cleaners, solvents, and acids, without undergoing degradation or discoloration. The specific finish employed dictates the level of chemical resistance. Some finishes are more susceptible to damage from certain chemicals, necessitating careful selection based on the intended application and potential exposure scenarios. Regular cleaning with inappropriate chemicals can compromise the integrity of the finish and accelerate deterioration.

- Impact Resistance

Impact resistance describes the ability of the finished surface to withstand sudden impacts without denting, cracking, or otherwise sustaining structural damage. The thickness and hardness of the finish, as well as the inherent density of the underlying birch wood, contribute to impact resistance. Thicker, more resilient finishes provide greater protection against impact damage, particularly in applications where the surface is prone to being struck by objects. The use of harder birch species can also enhance overall impact resistance.

These facets of surface durability collectively determine the overall performance and lifespan of finished birch in various applications. Understanding the interplay between these factors allows for informed material selection and appropriate finishing techniques, ensuring that the treated surface meets the specific demands of its intended use.

3. Workability Factor

The term “workability factor,” when applied to treated birch wood, encompasses the material’s ease of manipulation and shaping during manufacturing processes. This characteristic directly influences production efficiency, cost-effectiveness, and the complexity of designs achievable. A high workability factor translates to reduced tooling wear, lower energy consumption, and minimized waste during machining and assembly.

- Machining Properties

Birch, in its finished state, generally exhibits favorable machining properties. It can be readily sawn, planed, and routed without excessive splintering or tear-out. The density of the wood, combined with the application of a finish, contributes to dimensional stability during machining. However, the type and condition of cutting tools are critical to achieving clean, precise cuts. Dull tools can lead to increased friction, heat buildup, and a degraded surface finish.

- Fastening Performance

The ability of treated birch to accept and retain fasteners, such as screws and nails, is an important aspect of its workability. The wood’s density provides adequate holding power for most common fasteners. Pre-drilling pilot holes is recommended, particularly when working near the edges of the material or when using hardwoods screws. The finish applied to the surface can influence fastening performance; thicker finishes may require slightly longer fasteners to ensure secure attachment.

- Adhesive Bonding

The effectiveness of adhesive bonding is crucial in many woodworking applications involving treated birch. The wood’s surface characteristics, including its porosity and cleanliness, play a significant role in bond strength. Thorough surface preparation, such as sanding and cleaning, is essential to remove contaminants and create a suitable bonding surface. The choice of adhesive should be compatible with both the wood and the finish applied, with considerations given to open time, clamping pressure, and curing conditions. The type of adhesive will have an impact on how well the wood pieces will adhere to each other.

- Finishing Receptivity

While the term “finished birch wood” implies a completed surface treatment, the wood’s receptivity to additional finishing processes remains relevant, especially in situations where repairs or modifications are required. The existing finish should be properly prepared to ensure adequate adhesion of subsequent coatings. Light sanding or the application of a bonding agent may be necessary to create a suitable surface for refinishing. The compatibility of different finish types should also be considered to avoid adverse reactions, such as lifting or discoloration.

In summary, the workability of finished birch wood is a multifaceted characteristic that impacts various aspects of the manufacturing process. Optimizing machining parameters, fastening techniques, adhesive selection, and finishing procedures can maximize efficiency, minimize waste, and enhance the overall quality of the finished product. The properties help to ensure the surface has longevity and visual appeal.

4. Cost-Effectiveness

The cost-effectiveness associated with finished birch wood arises from a combination of factors impacting material acquisition, processing costs, and lifecycle expenses. Initial material costs are generally lower compared to premium hardwoods such as oak or maple, while the application of a finish enhances durability and reduces the need for frequent replacements. This combination contributes to a more favorable total cost of ownership. The relative abundance of birch resources, coupled with efficient processing techniques, directly influences its affordability in the market. For example, cabinet manufacturers frequently utilize finished birch wood as a substrate for veneers or laminate overlays, achieving a high-end aesthetic at a reduced material cost. The increased durability derived from the finishing process results in fewer warranty claims and lower long-term maintenance expenses, further solidifying its cost-effective nature.

The impact of processing costs on the overall cost-effectiveness must also be considered. Birch exhibits excellent machining properties, leading to reduced tooling wear and lower energy consumption during shaping and finishing operations. Its consistent grain pattern allows for efficient utilization of materials, minimizing waste during cutting and fabrication processes. These factors translate into lower production costs for manufacturers, who can then offer finished products at competitive prices. Consider the construction of furniture components; finished birch can be easily milled into intricate shapes, reducing labor costs and minimizing material loss compared to more challenging hardwoods. The ability to readily accept various finishes, from simple sealants to complex staining techniques, provides manufacturers with flexibility in meeting diverse market demands without incurring significant additional costs.

In conclusion, the cost-effectiveness of finished birch wood stems from its affordable initial material cost, efficient processing characteristics, and enhanced durability achieved through the finishing process. This confluence of factors makes it a viable alternative to more expensive hardwoods in a wide range of applications, including furniture manufacturing, cabinet construction, and interior finishing. The importance of understanding these economic advantages is crucial for informed decision-making in material selection, allowing businesses and consumers alike to maximize value without compromising quality or aesthetic appeal. The challenge lies in balancing cost considerations with the specific performance requirements of the intended application to ensure optimal long-term satisfaction.

5. Finish Options

The selection of finish options is a critical determinant in realizing the full potential of surfaces created from treated birch lumber. These options extend beyond mere aesthetics, impacting durability, maintenance requirements, and overall suitability for specific applications. Understanding the nuances of various finishing techniques is essential for optimizing both performance and visual appeal.

- Clear Coating Systems

Clear coating systems, such as varnishes, lacquers, and polyurethanes, are designed to protect the underlying birch wood while allowing its natural grain and color to remain visible. These finishes create a transparent barrier against moisture, scratches, and UV damage. Their role is primarily functional, enhancing durability without altering the wood’s inherent appearance. An example includes clear polyurethane applied to birch furniture in residential settings to protect against daily wear and tear while showcasing the wood’s natural beauty. The implications include extended lifespan and reduced maintenance frequency compared to unfinished surfaces.

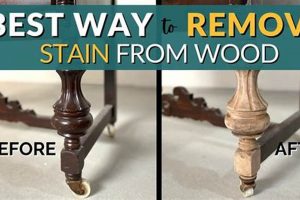

- Staining Techniques

Staining involves the application of pigments to alter the color of the birch wood, ranging from light, natural tones to dark, rich hues. Staining allows the material to emulate the appearance of more expensive wood species or to complement specific design palettes. For instance, a dark walnut stain may be applied to birch cabinets to achieve a traditional aesthetic. The implications encompass expanded design possibilities and the ability to create custom color matches, offering versatility beyond the wood’s natural coloration.

- Paint Application

Painting offers a fully opaque coating, completely concealing the wood grain and providing a uniform color across the surface. This option is frequently chosen when precise color matching or a specific design aesthetic necessitates a departure from the wood’s natural appearance. Painted birch is common in kitchen cabinetry and trim work, where color consistency and durability are paramount. The implications include the ability to integrate the material seamlessly into any color scheme and provide a durable, washable surface.

- Specialty Finishes

Specialty finishes encompass a range of techniques, including distressing, glazing, and antiquing, which are used to create unique visual effects and add character to the finished surface. These techniques can simulate the appearance of aged or weathered wood, adding depth and texture to the material. A distressed finish on birch furniture can evoke a rustic or vintage aesthetic. The implications involve enhancing visual interest and creating distinctive design elements that differentiate the material from standard finishes.

These finish options, when carefully selected and applied, are essential for realizing the full potential of treated birch. Each option offers distinct advantages in terms of aesthetics, durability, and maintenance requirements. Understanding these nuances allows for informed decision-making in material selection and finishing processes, ensuring that the final product meets the specific needs and expectations of the intended application. Furthermore, the combination of various techniques can create a truly customized final surface.

6. Grain Pattern

The grain pattern of birch wood, a defining characteristic, significantly influences the aesthetic and functional properties of “finished birch wood.” The term refers to the alignment and arrangement of wood fibers, presenting visual patterns that range from straight and uniform to wavy and figured. This pattern is not merely decorative; it directly impacts the wood’s strength, stability, and its ability to accept finishes. The relatively fine and closed grain of birch contributes to its smooth surface texture, making it receptive to a variety of finishes, from transparent coatings that highlight the natural wood tone to opaque paints that require a consistent and even substrate. The choice of birch wood with specific grain characteristics, therefore, is a critical decision in achieving desired design outcomes.

Consider, for instance, the use of birch plywood with a rotary-cut veneer in cabinet construction. This cutting method produces a broad, sweeping grain pattern, which, when finished, can create a visually appealing surface, particularly in contemporary designs. However, this same grain pattern may be less desirable for intricate carvings or detailed moldings, where the uniformity of the grain becomes more important. Conversely, solid birch wood with a tighter, more vertical grain is often selected for furniture components that require structural integrity and resistance to warping. The finishing process then enhances these inherent qualities, providing a protective layer that further stabilizes the wood and accentuates its natural grain.

In summary, the grain pattern of birch wood is an intrinsic component that directly impacts the final appearance, performance, and application of finished products. Careful consideration of grain orientation, figure, and density is essential for maximizing the benefits of birch wood in various woodworking projects. The challenges in working with birch often revolve around managing variations in grain pattern to ensure consistent finish absorption and minimizing potential warping or cracking. The knowledge and appropriate selection of birch wood based on grain characteristics are crucial for achieving desired aesthetic and functional outcomes, linking directly to the broader themes of material selection and design optimization.

7. Structural Stability

Structural stability, in the context of finished birch wood, denotes the material’s capacity to maintain its shape and resist deformation under applied loads or environmental stresses. The finishing process, while primarily aimed at enhancing aesthetics and surface durability, also contributes to structural stability by providing a protective barrier against moisture absorption and dimensional changes. The degree to which finishing impacts stability depends on the type of finish applied and the specific environmental conditions. Unfinished birch is susceptible to warping and swelling in fluctuating humidity levels, potentially compromising structural integrity. The application of a sealant or varnish reduces moisture permeability, mitigating these risks.

The inherent properties of birch, such as its density and grain orientation, fundamentally influence structural stability. Solid birch, with its relatively close grain, offers greater resistance to bending and compression compared to lower-density wood species. Birch plywood, engineered with alternating grain directions in its layers, further enhances dimensional stability, making it suitable for applications requiring large, flat surfaces. For example, birch plywood is frequently used in furniture construction and cabinetry, where maintaining flatness and resisting warping are essential for long-term performance. The selection of appropriate finishing techniques can complement these inherent properties, reinforcing the material’s ability to withstand stress. Consider the use of catalyzed conversion varnish on birch veneer; this finish provides a hard, durable surface that enhances resistance to scratching and impact, thereby preserving the structural integrity of the veneer.

In conclusion, structural stability is a crucial performance characteristic of finished birch wood, influenced by both the inherent properties of the wood itself and the application of appropriate finishing techniques. The selection of finishing materials and methods should consider the specific environmental conditions and loading requirements of the intended application. Understanding this relationship is essential for ensuring the long-term durability and structural integrity of products constructed from finished birch. While the finishing process itself contributes to stability, it is the combination of material selection, proper construction techniques, and appropriate finishing that ultimately determines the overall structural performance. The challenge lies in balancing aesthetic considerations with structural requirements to create products that are both visually appealing and structurally sound.

Frequently Asked Questions

The following questions address common inquiries and misconceptions regarding finished birch wood, providing clarity on its properties, applications, and maintenance.

Question 1: What distinguishes finished birch wood from unfinished birch wood?

Finished birch wood has undergone a surface treatment process, typically involving sanding, staining, and the application of a protective topcoat. This enhances its appearance, durability, and resistance to moisture and stains. Unfinished birch wood lacks this protective layer and is more susceptible to damage.

Question 2: In what applications is finished birch wood commonly used?

This material is frequently utilized in furniture manufacturing, cabinet construction, interior paneling, and millwork. Its smooth surface, light color, and ability to accept various finishes make it versatile for diverse design styles.

Question 3: How should finished birch wood surfaces be cleaned and maintained?

Regular dusting with a soft cloth is recommended. Spills should be cleaned immediately with a damp cloth. Abrasive cleaners and harsh chemicals should be avoided, as they can damage the finish. Periodic application of a wood polish or cleaner specifically designed for finished surfaces can help maintain its luster.

Question 4: Does the finish affect the structural properties of birch wood?

The finish primarily affects the surface properties, such as durability and resistance to moisture. While some finishes may add a slight degree of rigidity, the structural integrity of the wood is primarily determined by its inherent density, grain orientation, and construction techniques.

Question 5: Can finished birch wood be refinished or repaired if damaged?

Yes, finished birch wood can be refinished or repaired. The process typically involves sanding the existing finish, repairing any surface imperfections, and applying a new finish. It is recommended to consult with a qualified professional for significant repairs or refinishing projects.

Question 6: Is finished birch wood a sustainable material choice?

The sustainability of finished birch wood depends on the sourcing practices of the lumber and the environmental impact of the finishing materials used. Wood certified by organizations such as the Forest Stewardship Council (FSC) indicates responsible forest management. Water-based finishes are generally considered more environmentally friendly than solvent-based finishes.

These answers provide a foundation for understanding the key aspects of finished birch wood. Further research and consultation with industry professionals are encouraged for specific applications.

The following section explores the environmental considerations associated with finished birch wood in greater detail.

Conclusion

This exploration has demonstrated the multifaceted nature of finished birch wood, encompassing its aesthetic versatility, surface durability, workability factor, cost-effectiveness, finish options, grain pattern considerations, and structural stability implications. Each characteristic contributes to its overall suitability for diverse applications, ranging from furniture construction to interior design elements. The informed selection and appropriate utilization of this material necessitate a comprehensive understanding of these interrelated factors.

The continued evaluation of sustainable sourcing practices and the development of environmentally conscious finishing techniques remain crucial for maximizing the long-term viability and responsible application of finished birch wood. Further research into advanced finishing technologies and innovative construction methods will undoubtedly unlock new possibilities for this versatile and widely utilized material, further solidifying its relevance in both residential and commercial settings.