Coatings applied to wooden surfaces intended for contact with consumables must meet specific safety standards. These substances, designed to protect the wood and enhance its aesthetic appeal, should not leach harmful chemicals into food. Examples include certain cured oils, waxes, and resin-based products that have undergone rigorous testing and certification.

The selection of appropriate surface treatments is crucial for items like cutting boards, bowls, and utensils. Historically, natural oils like flaxseed and walnut have been used, but modern formulations offer improved durability and resistance to microbial growth. Utilizing verified safe treatments mitigates potential health risks and extends the lifespan of wooden kitchenware.

The following sections will detail the different types of safe treatments available, their application methods, and the criteria used to determine their suitability for food contact.

Essential Considerations

Proper selection and application of wood surface treatments are paramount for ensuring safety and longevity in food-related applications. The following points provide guidance on best practices.

Tip 1: Prioritize Certified Products: Verify that the chosen product has been independently tested and certified as compliant with relevant food safety regulations. Look for certifications from reputable organizations.

Tip 2: Understand Curing Times: Adhere strictly to the manufacturer’s recommended curing times. Insufficient curing can leave the coating vulnerable to leaching and premature degradation.

Tip 3: Preparation is Crucial: Thoroughly sand the wood surface to create a smooth, even base. Remove all dust and debris before applying any treatment.

Tip 4: Apply Thin, Even Coats: Avoid applying the treatment too thickly. Multiple thin coats are preferable to a single thick coat for optimal penetration and curing.

Tip 5: Maintain Cleanliness: Regularly clean treated surfaces with mild soap and water. Avoid harsh chemicals or abrasive cleaners, which can damage the coating.

Tip 6: Reapply Periodically: Depending on usage frequency, reapplication of the surface treatment may be necessary to maintain its protective properties. Monitor the surface for signs of wear or dryness.

Tip 7: Select Appropriate Wood: Certain wood species are naturally more resistant to moisture and microbial growth than others. Consider these inherent properties when selecting wood for food contact applications.

Implementing these practices will contribute to the creation of safer and more durable wooden items for culinary use.

The subsequent section offers a detailed analysis of various product options and their respective performance characteristics.

1. Non-toxic composition

The selection of a treatment with a non-toxic composition is foundational to the safety of wood items used in food preparation and consumption. The term refers to substances that, under reasonably foreseeable conditions of use, do not pose a health risk through ingestion or contact.

- Absence of Harmful Chemicals

The core attribute of a safe product lies in its formulation. It must be free from heavy metals, volatile organic compounds (VOCs), and other substances known to be carcinogenic, mutagenic, or otherwise harmful. Thorough testing and certification are essential to verify the absence of such chemicals.

- FDA Compliance

Regulations established by agencies such as the U.S. Food and Drug Administration (FDA) set stringent limits on the types and amounts of substances that can migrate from a surface treatment into food. Compliance with these regulations ensures that any incidental contact with is within acceptable safety thresholds.

- Inertness After Curing

The treatment must achieve a state of inertness after proper curing. This means that the cured substance should not react with food components, break down into harmful byproducts, or leach into the food itself. The curing process is critical to achieving this stable, non-reactive state.

- Allergen Considerations

Certain individuals may have allergies or sensitivities to specific ingredients. Thus, transparency in product labeling is important, allowing users to make informed choices and avoid potential allergic reactions. Products should clearly identify all components and potential allergens.

The above aspects underscore the critical role of a non-toxic composition in ensuring the safe use of wooden utensils and surfaces. By adhering to regulatory standards, understanding curing processes, and considering potential allergens, manufacturers and consumers can mitigate risks and promote safer food handling practices.

2. Curing Properties

The curing process is a critical determinant of the safety and performance of wood treatments intended for contact with food. Inadequately cured substances may leach harmful components or fail to provide adequate protection against moisture and microbial growth. The following details the vital elements of proper curing in relation to achieving a safely treated wood surface.

- Polymerization and Crosslinking

Curing often involves polymerization or crosslinking of the constituent molecules in the wood treatment. This process transforms the liquid coating into a solid, inert film. Incomplete polymerization can leave unreacted monomers, which may migrate into food. For example, certain oil-based treatments require sufficient exposure to air for proper crosslinking to occur, resulting in a stable and non-toxic surface.

- Volatile Compound Evaporation

Many wood coatings contain solvents or volatile organic compounds (VOCs) that evaporate during the curing process. Proper ventilation during curing is essential to ensure complete removal of these compounds. Residual VOCs can pose both a health risk and impart undesirable odors or tastes to food that comes into contact with the treated surface.

- Hardness and Durability Development

The curing process directly influences the hardness and durability of the final treatment. A well-cured finish provides a robust barrier against scratches, abrasions, and moisture penetration. Insufficient curing results in a softer, more vulnerable surface that is prone to damage and microbial colonization. The choice of product and adherence to recommended curing times are paramount for achieving optimal hardness and durability.

- Adhesion Enhancement

Curing promotes strong adhesion between the treatment and the wood substrate. Adequate adhesion prevents the finish from peeling or flaking, which can expose the underlying wood to moisture and contamination. Proper surface preparation, such as sanding and cleaning, combined with appropriate curing, maximizes adhesion and ensures a long-lasting, safe surface.

The interplay between these facets of curing properties is directly related to creating safe and durable coatings for wooden kitchenware. By understanding and controlling the curing process, manufacturers and end-users can optimize the performance of wood treatments and minimize the potential for adverse health effects associated with improperly cured surfaces. Rigorous adherence to product guidelines and best practices in application and curing are essential for ensuring the safety of items intended for culinary use.

3. Durability

Durability, in the context of treatments for wooden surfaces intended for contact with food, directly influences the long-term safety and hygiene of the treated item. A durable finish resists degradation from repeated cleaning, abrasion from utensils, and exposure to moisture. Consequently, a less durable finish is prone to developing cracks, chips, or a general breakdown of the surface layer. These imperfections create harbors for bacteria and other microorganisms, negating the intended sanitary properties of the item. The initial choice of a verified treatment is rendered ineffective if the resultant finish lacks the requisite resistance to wear and tear. For example, a butcher block treated with an inadequately durable coating will quickly show knife marks and scratches, providing entry points for pathogens.

The connection between durability and safety extends to the ease of cleaning and maintenance. A surface that is easily cleaned without damaging the protective layer maintains its barrier properties against moisture and bacterial penetration. Conversely, a less durable surface may require aggressive cleaning methods to remove contaminants, further compromising its integrity. Practical applications include wooden salad bowls and utensils, where repeated washing cycles can gradually erode a weak finish, leading to potential contamination of food. Selecting a treatment specifically formulated for its robust characteristics ensures the long-term viability and safety of these items.

In summary, durability is not merely a measure of longevity but a fundamental element in ensuring the continued safety of treated wooden surfaces used in culinary environments. Insufficient durability compromises the integrity of the treated surface, increasing the risk of bacterial contamination and rendering the item unsuitable for continued contact with food. The focus on durable treatments highlights a preventative approach to food safety, emphasizing the importance of selecting coatings that maintain their protective qualities over extended periods of use and cleaning.

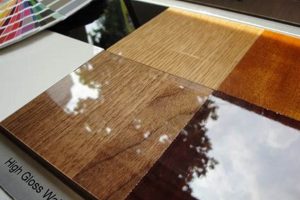

4. Application Method

The application method of treatments significantly influences the resulting safety and longevity of wooden surfaces designed for food contact. Improper application can compromise the intended protective qualities, even if the product itself is certified as safe. The uniformity and thickness of the coating, directly affected by the chosen application technique, dictate the degree of moisture resistance and the potential for leaching of chemical compounds into food. For example, a treatment sprayed too thinly on a cutting board may provide inadequate protection against knife marks and bacterial ingress, while a coating applied too thickly may not cure properly, increasing the risk of chemical migration.

Specific application methods, such as brushing, wiping, or spraying, necessitate different considerations regarding product viscosity and surface preparation. Brushing may introduce streaks or unevenness if not executed carefully, potentially creating areas of vulnerability. Wiping, while often providing a more controlled application, requires careful attention to ensuring complete coverage, especially in intricate areas of the wood surface. Spraying, though efficient, demands precise control of spray patterns and ventilation to avoid overspray and ensure uniform deposition. The adherence to manufacturer-specified application guidelines, including recommendations for surface preparation, number of coats, and drying times, is crucial for maximizing the treatment’s efficacy and safety.

In conclusion, the proper application of wood treatments is an integral component of achieving surfaces that are both aesthetically pleasing and safe for food contact. Suboptimal application techniques undermine the intrinsic properties of even the safest coatings, creating potential pathways for contamination and compromising the integrity of the wooden item. Emphasis on adherence to manufacturer instructions, meticulous surface preparation, and appropriate choice of application method ensures that the treatment functions as intended, providing a durable and safe barrier between the wood and consumables.

5. Regulatory compliance

Regulatory compliance constitutes a cornerstone in ensuring the safety of treatments used on wooden surfaces intended for contact with food. Adherence to established regulations, such as those promulgated by the U.S. Food and Drug Administration (FDA) or equivalent international bodies, serves to mitigate the potential risks associated with chemical migration from the surface into foodstuffs. These regulations delineate permissible substances, acceptable migration limits, and testing protocols, all designed to protect public health. Non-compliance can lead to the introduction of harmful chemicals into the food chain, posing a direct threat to consumer well-being. For instance, the use of unapproved varnishes containing lead or cadmium, though historically employed, would represent a clear violation of current regulatory standards and could result in severe health consequences.

The importance of regulatory adherence extends beyond mere legal obligation; it directly impacts product liability and consumer trust. Companies that demonstrably comply with relevant regulations enhance their credibility and demonstrate a commitment to providing safe products. Failure to comply can result in product recalls, legal action, and reputational damage. Furthermore, compliance often necessitates rigorous testing and quality control procedures, which in turn promote continuous improvement in product formulation and manufacturing processes. Consider the case of wooden cutting boards treated with finishes that do not meet FDA standards. Such products could leach formaldehyde or other harmful substances into the food, leading to potential health risks and legal repercussions for the manufacturer.

In conclusion, regulatory compliance is not simply a procedural requirement but an essential element in the creation and distribution of wood treatments deemed safe for food contact. By adhering to established standards, manufacturers can minimize risks, enhance consumer confidence, and ensure that their products do not pose a threat to public health. The ongoing development and enforcement of these regulations are vital for maintaining the integrity of the food supply and protecting consumers from potential harm.

Frequently Asked Questions

This section addresses common inquiries concerning the safety of surface treatments used on wooden items intended for contact with food.

Question 1: What constitutes a truly safe coating for wooden cutting boards?

A truly safe coating for wooden cutting boards must be demonstrably non-toxic, fully cured to prevent leaching, and compliant with relevant regulatory standards, such as those set by the FDA. It should also exhibit resistance to moisture and microbial growth.

Question 2: How can one verify that a product is indeed suitable for use on kitchenware?

Verification involves scrutinizing product labels for certifications from reputable testing organizations, reviewing Material Safety Data Sheets (MSDS) for ingredient information, and confirming compliance with applicable food safety regulations.

Question 3: Are all-natural treatments inherently safer than synthetic alternatives?

The “all-natural” designation does not automatically equate to safety. Some natural substances can be allergenic or may not provide adequate protection against bacterial contamination. Rigorous testing and certification are necessary to determine the safety of any treatment, regardless of its origin.

Question 4: What are the potential health risks associated with using non-compliant surface treatments?

The potential health risks include ingestion of harmful chemicals, allergic reactions, and exposure to toxins that may leach into food. Long-term exposure to such substances can contribute to a range of adverse health effects.

Question 5: How does the application method impact the safety of the treated wood?

The application method directly affects the uniformity, thickness, and curing of the coating. Improper application can compromise the protective barrier, leading to increased moisture absorption and potential leaching of chemicals. Adherence to manufacturer guidelines is critical.

Question 6: What maintenance practices are recommended to ensure the continued safety of treated wooden items?

Recommended maintenance practices include regular cleaning with mild soap and water, avoiding harsh chemicals or abrasive cleaners, and periodic reapplication of the treatment as needed to maintain its protective properties.

In summary, the selection and maintenance of surface treatments require careful consideration of product composition, regulatory compliance, and proper application techniques.

The following section will offer guidance on selecting specific products based on intended use and performance characteristics.

Conclusion

The preceding analysis has underscored the critical importance of selecting appropriate treatments for wooden items intended for contact with food. Considerations of non-toxic composition, curing properties, durability, application method, and regulatory compliance are paramount to ensuring the safety and longevity of these products. The potential consequences of utilizing substandard or improperly applied treatments range from aesthetic degradation to significant health risks, necessitating a rigorous approach to product selection and application.

Therefore, a commitment to informed decision-making is essential for both manufacturers and consumers. Prioritizing certified products, adhering to established best practices, and maintaining a vigilant approach to product maintenance are vital steps in safeguarding public health. The continued development and enforcement of stringent regulatory standards will further contribute to the creation of safer and more sustainable practices within the industry.