The selection between finer gauge fasteners centers on the balance between holding power and the visibility of the resulting hole. One type, generally thicker, provides greater shear strength for heavier trim work. The other, being thinner, minimizes surface disruption and reduces the need for filling and sanding. Considerations for project requirements often dictate fastener choice.

Employing the appropriate fastener can significantly affect a projects longevity and aesthetic appeal. Historically, craftsmen relied on nail size and hammering technique to achieve desired results; modern pneumatic nailers offer increased precision and efficiency. The choice influences the final appearance and structural integrity, proving critical for both amateur and professional projects.

This article explores the distinctions in size, application, tool compatibility, and overall suitability for diverse woodworking and construction tasks. A comparative analysis aids in determining the optimal solution for various project needs. Subsequent sections will delve into specific aspects of these fasteners, offering guidance for informed decision-making.

Selection and Application Guidelines

Optimal outcomes when employing either fastener type depend on careful selection and proper application. The following tips provide essential guidelines for maximizing performance and minimizing potential issues.

Tip 1: Material Density Consideration: When working with hardwoods, pre-drilling pilot holes is advisable, regardless of the chosen fastener. This prevents wood splitting and ensures consistent driving depth. For softer woods, pre-drilling is typically unnecessary but may be beneficial to control fastener placement precisely.

Tip 2: Nailer Compatibility: Ensure the pneumatic nailer is specifically designed for the selected fastener. Using incorrect fasteners in a nailer can cause jams, damage the tool, or result in improper driving. Refer to the nailer’s manual for approved fastener types and sizes.

Tip 3: Countersinking Depth: Adjust the nailer’s depth setting to achieve the desired countersinking. For a seamless finish, aim for a slight countersink that allows for filling without protruding. Over-driving creates excessive surface damage.

Tip 4: Joint Strength Requirements: For structural joints or applications requiring significant holding power, the thicker option is generally preferred. Supplement with wood glue for enhanced strength and longevity. Consider mechanical fasteners like screws for critical structural elements.

Tip 5: Concealment Strategy: When concealment is paramount, the smaller gauge is favored. Employ wood filler that closely matches the surrounding material to minimize visibility. Practice filler application techniques to achieve a smooth, undetectable repair.

Tip 6: Avoiding Grain Splitting: Angle fastener placement to follow the wood grain. Driving perpendicular to the grain increases the risk of splitting, particularly near edges. Stagger fastener patterns to distribute stress and minimize the likelihood of cracking.

Tip 7: Proper Nail Length: Select a length that penetrates sufficiently into the substrate for adequate holding power, but avoids protruding through the back. A general rule is to have approximately two-thirds of the fastener length embedded in the receiving material.

Adhering to these recommendations enhances the effectiveness of each fastener and ensures projects meet both structural and aesthetic standards. Understanding material properties, tool capabilities, and desired outcomes contributes to optimal results.

The subsequent section will summarize the key differences and provide a decision-making framework for selecting the appropriate fastener for specific tasks.

1. Gauge

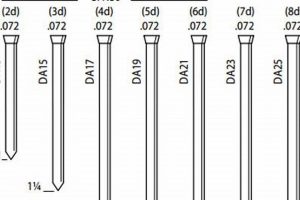

Gauge, when discussing fine fasteners, refers to the diameter of the nail shank. This measurement is inversely proportional; a higher gauge number indicates a thinner nail. The gauge is a primary differentiator between fastener types and directly impacts both holding power and aesthetic considerations.

- Definition of Gauge and Measurement Systems

Gauge is commonly used to specify the diameter of finish and brad nails. A higher gauge number corresponds to a smaller diameter, measured in fractions of an inch or millimeters. Understanding the gauge measurement is crucial in selecting the appropriate fastener for a given task. Deviations in gauge can lead to tool malfunction or project failure.

- Impact on Holding Power

The gauge directly correlates with the fastener’s shear strength and holding capacity. Thicker nails, those with lower gauge numbers, provide greater resistance to lateral forces and are suitable for heavier materials or applications requiring robust joints. Conversely, thinner nails offer reduced holding power but minimize the risk of splitting delicate workpieces.

- Aesthetic Considerations and Visibility

A significant advantage of higher gauge nails is their minimal visual impact. The smaller diameter creates a less noticeable entry point, reducing the need for extensive filling and sanding. This is particularly important in applications where a clean, unblemished finish is desired, such as fine trim work or cabinet facing. Lower gauge nails leave more prominent holes requiring more extensive cosmetic work.

- Compatibility with Nail Guns and Tools

Nail guns are designed to accommodate specific gauge ranges. Using an incorrect gauge can damage the tool or result in improper nail driving. Each type of fastener requires specific magazines and driving mechanisms. Mismatching can cause jams, misfires, and potential safety hazards.

The selection of fastener gauge fundamentally influences the structural integrity and visual appeal of finished projects. Careful consideration of material properties, holding power requirements, and aesthetic goals is essential. This attribute forms a crucial basis for distinguishing between various fastener types and selecting the optimum choice.

2. Head Size

The head’s dimensions represent a critical factor differentiating between fine fasteners, influencing both holding capability and aesthetic result. Head size must be assessed in conjunction with material characteristics and intended application.

- Definition of Head Size and Measurement

Head size refers to the diameter and shape of the fastener’s head. Measurements are typically expressed in fractions of an inch or millimeters. Heads vary in style (e.g., straight, cupped, countersinking) to serve diverse functions. Precise measurement ensures correct countersinking or surface contact.

- Impact on Holding Power and Pull-Through Resistance

Larger heads provide greater surface area, increasing resistance to pull-through, particularly in softer materials. However, the increased visibility may necessitate more extensive filling and sanding. Smaller heads are less resistant to pull-through but offer a cleaner, less conspicuous finish.

- Aesthetic Considerations and Concealment

The smaller head is often preferred for applications prioritizing aesthetics. The reduced surface disruption minimizes the need for filling and blending. Larger heads, while providing enhanced holding, require careful concealment to maintain visual appeal. Selection depends on balancing structural requirements with aesthetic goals.

- Role in Countersinking and Surface Finishing

Head size dictates the extent of countersinking required for a flush or concealed finish. Smaller heads readily countersink with minimal surface damage, while larger heads necessitate deeper countersinking or specialized tools. The chosen head size impacts the finishing process and overall appearance.

The head’s dimensions form a pivotal element in selecting the optimal fastener. Balancing holding strength with visual demands determines the suitability of various fastener types across a range of projects. Evaluating these parameters ensures both structural soundness and aesthetic satisfaction.

3. Holding Power

Holding power, a primary determinant in fastener selection, directly influences the structural integrity and longevity of assembled components. The diameter of the fastener, a key distinction between thinner fasteners and thicker fasteners, is proportionally linked to its shear strength and resistance to pull-out forces. Consequently, the choice impacts the durability of the connection under load and stress. For example, when attaching substantial crown molding, the increased diameter of a thicker option provides greater resistance to gravitational forces and potential impacts, preventing detachment over time. Conversely, attempting to secure delicate trim work with a thicker fastener may result in splitting the wood, negating any advantage in holding power. Properly understanding holding power ensures material integrity.

The substrate material significantly affects achieved holding power. Softer woods, such as pine, offer less resistance to fastener withdrawal compared to hardwoods like oak or maple. Therefore, projects involving softwoods may necessitate longer fasteners or alternative fastening methods to compensate for the reduced grip. Cabinet construction, for example, often utilizes a combination of adhesives and fasteners for optimal joint strength. While fine gauge fasteners might be used to temporarily hold pieces in place during glue drying, thicker gauge fasteners are employed in areas subject to greater stress, such as drawer supports or frame connections. Applying holding power to project elements increases stability and safety.

In summary, holding power constitutes a crucial factor in the comparison of finer gauge fasteners. The interaction between fastener diameter, substrate density, and applied load determines the suitability of each for a given application. Failure to account for these variables can compromise structural integrity, leading to premature failure or aesthetic deficiencies. Therefore, a comprehensive understanding of holding power principles is essential for informed decision-making and successful project completion. These fasteners, however, are not suitable for load-bearing purposes in framing projects.

4. Material Thickness

Material thickness exerts a significant influence on fastener selection, dictating the appropriate length and gauge necessary for secure and lasting connections. The inherent properties of the material, coupled with its dimensions, determine the load-bearing capacity and resistance to splitting. Therefore, careful assessment of material thickness is paramount when deciding between finer gauge fasteners and heavier options.

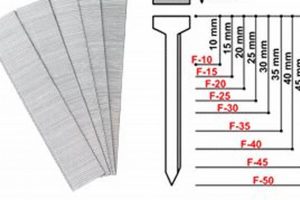

- Optimal Nail Length Calculation

The length of the fastener should be proportional to the thickness of the materials being joined. A general guideline suggests that the nail should penetrate at least two-thirds of its length into the receiving material for adequate holding power. For instance, securing a 1/2-inch trim piece to a solid wood frame requires a fastener long enough to pass through the trim and penetrate a sufficient depth into the frame, typically necessitating a length exceeding 1 inch. Failure to adhere to this principle can result in weak joints prone to failure under stress. When using brad nails with thinner materials, ensuring the nail doesn’t protrude through the back is crucial for a clean finish.

- Splitting Risk Mitigation in Thin Stock

When working with thin or brittle materials, such as delicate molding or veneer, the risk of splitting increases substantially. In such cases, finer gauge nails, like brads, are preferred due to their reduced diameter, which minimizes stress on the surrounding wood fibers. Pre-drilling pilot holes can further mitigate splitting, particularly in hardwoods or dense materials. Conversely, attempting to drive a thicker nail into thin stock invariably leads to damage and compromised aesthetics.

- Holding Power Requirements and Material Density

Material thickness often correlates with the required holding power. Thicker materials typically necessitate stronger connections to withstand heavier loads or greater stress. While finer gauge nails may suffice for attaching lightweight decorative elements, securing thicker components, such as cabinet face frames, often demands the superior holding power of thicker options. Furthermore, the density of the material also plays a role; denser materials offer greater resistance to nail withdrawal, allowing for shorter fasteners or finer gauges.

- Impact on Countersinking and Finishing

The thickness of the material influences the depth of countersinking required for a seamless finish. Thicker materials can accommodate deeper countersinking without compromising structural integrity, allowing for more extensive filling and blending. In contrast, thin materials may limit the extent of countersinking, requiring more precise nail placement and minimal filling to avoid visible imperfections. Selecting the appropriate fastener and countersinking technique is essential for achieving a professional-looking result. If a brad nail is too long for the material, it can bend over upon exiting, creating a “fish hook” effect that is difficult to conceal.

In conclusion, material thickness constitutes a critical parameter in the selection process between finer gauge fasteners and heavier options. A comprehensive understanding of the interplay between material thickness, fastener length, holding power requirements, and splitting risk is essential for achieving secure, durable, and aesthetically pleasing results. Careful consideration of these factors ensures that the chosen fastener is appropriately matched to the specific demands of the project.

5. Application

The intended use case plays a pivotal role in determining the appropriate fastener. Selecting between a thinner or thicker fastener necessitates a thorough understanding of the specific demands of the project at hand. Load-bearing requirements, aesthetic considerations, and material properties all influence the decision-making process.

- Trim Work and Molding Installation

In delicate trim and molding applications, minimizing surface disruption is paramount. Finer gauge fasteners, like brads, are often preferred due to their smaller diameter, which reduces the risk of splitting thin or brittle materials. Examples include installing crown molding, picture frames, or intricate decorative accents. These fasteners provide sufficient holding power for lightweight elements while maintaining a clean, professional appearance. Overusing heavier fasteners can result in visible damage and necessitate extensive repairs.

- Cabinetry and Furniture Construction

Cabinetry and furniture projects frequently require a balance between holding strength and aesthetic finesse. Thicker fasteners offer increased shear strength and resistance to pull-out, making them suitable for securing face frames, drawer boxes, and other structural components. In areas where fastener visibility is a concern, filling and sanding techniques can be employed to achieve a seamless finish. Conversely, finer gauge fasteners may be used for attaching decorative panels or lightweight backing materials. Correct application helps to ensure the final product durability and appearance.

- Baseboard and Paneling Attachment

Attaching baseboards and paneling often necessitates the use of fasteners capable of penetrating through multiple layers of material. While thinner fasteners may be sufficient for securing thin paneling to a solid substrate, thicker baseboards typically require the superior holding power of a more substantial fastener. The length and gauge of the nail should be carefully selected to ensure adequate penetration without protruding through the back or splitting the material. Inconsistent fastener selection can lead to loose baseboards and visible gaps over time.

- Craft Projects and Hobby Applications

In craft projects and hobby applications, the choice of fastener is often dictated by the scale and nature of the project. Finer gauge nails are well-suited for delicate tasks, such as assembling small boxes, attaching fabric to frames, or creating miniature models. Their minimal visual impact allows for a clean and unobtrusive finish. Heavier gauge fasteners may be employed for projects requiring greater structural integrity, such as building birdhouses or constructing small furniture pieces. Selecting suitable fasteners to the project, will make that project last for years to come.

Ultimately, the decision between thinner and thicker fasteners hinges on a comprehensive assessment of the specific application. By carefully considering the load-bearing requirements, aesthetic considerations, and material properties involved, one can select the fastener that best balances performance, durability, and visual appeal. The range of applications are vast and varied, therefore, knowing the details for each is crucial for project success.

6. Tool Compatibility

The operational effectiveness of fine gauge fasteners is intrinsically linked to tool compatibility. Pneumatic nailers are engineered to accommodate specific fastener gauges and lengths. Mismatched fasteners can induce tool malfunction, project compromised quality, and potential safety hazards. Therefore, selecting a nailer that precisely matches the intended fastener is a crucial preliminary step in any construction or woodworking endeavor. For example, a nailer designed for 18-gauge brads will invariably jam or misfire if loaded with thicker 15- or 16-gauge finish nails. This incompatibility arises from dimensional differences in the fastener magazines, driving mechanisms, and nosepiece configurations. Understanding and adhering to tool specifications mitigates the risk of equipment damage and ensures proper fastener deployment.

Practical implications of mismatched tools and fasteners manifest in various ways. Incorrect fastener loading can cause bent or misshapen nails, inconsistent driving depths, and damage to the workpiece. Repeated jamming may lead to premature wear and tear on the nailer itself, necessitating costly repairs or replacements. Furthermore, improperly driven fasteners compromise the structural integrity of the joint, potentially leading to weakened connections and eventual failure. Consider a scenario where an attempt is made to drive finish nails with a brad nailer; the narrower driving mechanism lacks the force and precision required to properly set the larger nail head, resulting in protruding nails and marred surfaces. Conversely, using brads in a finish nailer may cause the brads to bend or break within the tool, rendering it inoperable. Checking the nailer manual is important to know tool compatibility.

In summary, tool compatibility represents a non-negotiable element in the utilization of finish and brad nails. The consequences of ignoring this fundamental principle extend beyond mere inconvenience, potentially resulting in equipment damage, compromised project quality, and elevated safety risks. Careful attention to tool specifications and fastener compatibility is paramount for achieving optimal performance and ensuring successful outcomes in any woodworking or construction application.

Frequently Asked Questions

The following addresses common inquiries regarding the appropriate selection and utilization of fine gauge fasteners.

Question 1: What constitutes the primary difference between finish nails and brad nails?

The core distinction resides in gauge, or diameter. Finish nails exhibit a larger gauge, offering greater holding power, while brad nails, being thinner, minimize surface disruption.

Question 2: When is a brad nail preferred over a finish nail?

Brad nails are generally preferred for delicate trim work, thin materials, or applications where minimal visibility is desired. Their smaller diameter reduces the risk of splitting and creates a less conspicuous hole.

Question 3: For which applications are finish nails most suitable?

Finish nails are better suited for heavier trim, baseboards, cabinetry, and other applications requiring increased holding strength. Their larger diameter provides greater resistance to pull-out and shear forces.

Question 4: Can finish nails and brad nails be used interchangeably?

Interchangeability is limited and depends on the specific application. While a finish nail might suffice where a brad nail is recommended, the reverse is often not true. The structural demands and aesthetic requirements should dictate the choice.

Question 5: Does material density influence the selection between these fastener types?

Absolutely. Softer woods generally require longer fasteners to achieve adequate holding power, regardless of gauge. Hardwoods, conversely, may be more prone to splitting, necessitating finer gauges or pre-drilling.

Question 6: What are the potential consequences of selecting the wrong fastener type?

Incorrect selection can lead to a range of problems, including splitting the workpiece, inadequate holding power, visible nail holes, and compromised structural integrity. Careful consideration of project requirements is crucial.

Understanding these nuances allows for informed decision-making and optimal results when working with these fasteners.

The next article section will provide a summary, highlighting key considerations for selecting the appropriate fastener.

Finish Nails vs Brad Nails

This exposition clarifies the distinctions between finish nails vs brad nails, emphasizing the significance of informed fastener selection for optimal project outcomes. Key considerations include gauge, head size, holding power, material thickness, application requirements, and tool compatibility. These factors collectively influence structural integrity, aesthetic quality, and long-term durability.

Mastery of fastener selection elevates the standard of craftsmanship. Ongoing education and adherence to best practices ensure consistently superior results in diverse construction and woodworking endeavors. The judicious application of these principles leads to projects that are not only structurally sound but also visually refined, reflecting a commitment to excellence.