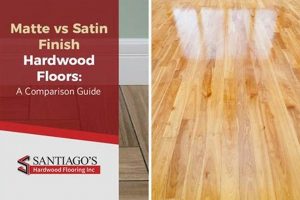

Floor finishes significantly impact the aesthetic and practical qualities of interior spaces. Two popular options offer distinct visual and functional characteristics. One provides a subtle sheen, reflecting light gently and offering a smooth tactile experience. The other minimizes light reflection, resulting in a non-glossy appearance with a more textured feel. These finishes cater to different design preferences and usage requirements.

The selection of an appropriate floor sealant is critical because it influences the durability, maintenance needs, and overall ambiance of a room. Historically, choices were limited, but advancements in polymer technology have expanded available options. Modern formulations offer enhanced resistance to scratches, staining, and wear, making them suitable for high-traffic areas. Furthermore, the visual impact can dramatically alter the perceived size and style of a space, contributing to its overall value and appeal.

Considering the nuanced differences in appearance, application, maintenance, and durability is essential when choosing between these surface treatments. Factors such as the type of flooring material, the amount of natural light in the room, and the desired level of slip resistance should all inform the decision-making process. The following sections will delve into these critical aspects to provide a comprehensive understanding of each option.

Considerations for Selecting Floor Finishes

The appropriate selection of floor sealant directly impacts the longevity, maintenance demands, and visual characteristics of flooring installations. These recommendations facilitate informed decision-making.

Tip 1: Evaluate Ambient Lighting: Assess the amount of natural and artificial light within the space. Surfaces with minimal sheen may be preferable in brightly lit areas to reduce glare, while subtly reflective surfaces can enhance illumination in darker rooms.

Tip 2: Analyze Traffic Levels: High-traffic areas necessitate finishes with superior scratch resistance and durability. Opt for formulations specifically designed to withstand frequent use and potential abrasion.

Tip 3: Determine Desired Slip Resistance: Prioritize slip resistance, particularly in environments prone to moisture or where safety is paramount. Texturing agents or specialized coatings can enhance traction.

Tip 4: Match Finish to Flooring Material: Ensure compatibility between the sealant and the underlying flooring material. Certain formulations may not adhere properly to specific surfaces, resulting in premature wear or delamination.

Tip 5: Consider Maintenance Requirements: Evaluate the long-term maintenance obligations associated with each option. Finishes requiring frequent buffing or specialized cleaning products may increase upkeep costs.

Tip 6: Assess Aesthetic Preferences: Align the chosen finish with the intended design aesthetic. Surfaces offering muted light reflection tend to create a more understated and contemporary appearance, whereas options with slight sheen can provide a more traditional and elegant look.

Tip 7: Test Before Full Application: Prior to applying any sealant to the entire floor, conduct a test application in an inconspicuous area. This allows for assessment of the finish’s appearance, adhesion, and compatibility with the flooring material.

The selection of an optimal surface treatment involves careful consideration of factors ranging from lighting conditions to maintenance demands. By weighing these factors, a durable and aesthetically pleasing flooring solution can be achieved.

The concluding section will provide a comprehensive summary of the key considerations and best practices discussed, along with resources for further exploration of floor finishing techniques and product options.

1. Light Reflectivity

Light reflectivity, a fundamental property of any surface, plays a pivotal role in how a floor finish interacts with the surrounding environment. The degree to which a surface reflects light directly influences perceived brightness, depth, and texture, thus making it a critical consideration in selecting between sealant options.

- Gloss Level and Light Diffusion

A higher gloss level results in specular reflection, where light bounces off the surface at an angle equal to the angle of incidence. This creates a mirror-like effect, potentially amplifying brightness but also highlighting imperfections. Conversely, a lower gloss level promotes diffuse reflection, scattering light in multiple directions. This minimizes glare and provides a softer, more uniform appearance, concealing minor surface flaws.

- Impact on Perceived Space

Surfaces that readily reflect light can visually expand a space, making it appear larger and more open. This effect is particularly pronounced in rooms with limited natural light. In contrast, surfaces with minimal light reflection can create a sense of intimacy and warmth, albeit potentially at the expense of perceived spaciousness. The choice therefore depends on the desired ambiance and the existing spatial characteristics.

- Influence on Color Perception

The intensity and direction of reflected light can alter the perceived color of the flooring material. High gloss surfaces may exhibit a “washed-out” appearance under intense illumination, while lower gloss finishes tend to render colors more accurately. The selection should account for the interplay between the finish’s reflective properties and the floor’s inherent color to achieve the intended visual effect.

- Practical Implications for Maintenance

Highly reflective surfaces often require more diligent cleaning to maintain their pristine appearance, as dust, smudges, and scratches become readily visible. Surfaces that diffuse light are more forgiving, concealing minor imperfections and reducing the frequency of necessary cleaning interventions. The practicality of the chosen finish, therefore, must align with the anticipated maintenance regime.

These distinct interactions with light establish a fundamental difference between sealant types. Consideration of the trade-offs between brightness amplification, imperfection concealment, color fidelity, and maintenance demands is crucial for selecting the most appropriate solution. The goal is to create a flooring surface that not only complements the overall design but also performs optimally under the specific environmental conditions.

2. Durability

Durability constitutes a primary factor in the selection of floor finishes. The capacity of a surface treatment to withstand abrasion, impact, and chemical exposure directly impacts its longevity and overall life-cycle cost. The choice between finishes with varying sheen levels should consider the demands of the intended environment and the anticipated levels of traffic and wear.

- Abrasion Resistance and Traffic Volume

Abrasion resistance refers to the ability of a finish to resist scratching and wear caused by foot traffic, furniture movement, and the introduction of particulate matter. High-traffic areas, such as hallways and commercial spaces, necessitate finishes with superior abrasion resistance. Formulations incorporating ceramic particles or enhanced polymer crosslinking offer improved protection against surface damage, regardless of the final sheen level. Testing standards, such as the Taber abrasion test, provide quantitative measures of a finish’s ability to withstand abrasive forces.

- Impact Resistance and Potential for Damage

Impact resistance dictates the ability of a finish to withstand sudden forces without cracking or chipping. This is particularly relevant in areas prone to dropped objects or heavy impacts. Finishes with greater flexibility and elasticity can better absorb impact energy, minimizing the risk of structural damage. The substrate material also influences impact resistance; for instance, a hardwood floor finished with a resilient coating will generally exhibit greater impact resistance than a concrete floor with a brittle coating.

- Chemical Resistance and Spill Management

Chemical resistance defines the ability of a finish to withstand exposure to cleaning agents, spills, and other potentially corrosive substances. Kitchens, bathrooms, and industrial environments often require finishes with high chemical resistance. Polyurethane-based finishes typically offer superior chemical resistance compared to wax-based or acrylic formulations. Prompt spill cleanup is crucial, regardless of the finish type, to prevent staining or degradation.

- UV Resistance and Color Stability

UV resistance refers to the ability of a finish to withstand prolonged exposure to ultraviolet radiation without fading, yellowing, or undergoing other forms of degradation. Finishes lacking UV inhibitors may exhibit significant color changes over time, particularly in areas with direct sunlight exposure. UV-resistant formulations incorporate additives that absorb or reflect ultraviolet radiation, preserving the finish’s original appearance. Regular maintenance, such as recoating, can further extend the lifespan and color stability of the finish.

The interplay between these factors dictates the long-term performance of a floor finish. A careful assessment of the environmental conditions and anticipated usage patterns is essential for selecting a durable and aesthetically pleasing surface treatment. Selecting a flooring treatment isn’t just about looks; it’s an investment in a surface’s resilience and longevity.

3. Maintenance

The maintenance requirements associated with floor finishes are directly influenced by the chosen sheen level. Finishes with higher sheen, such as satin, often necessitate more frequent and meticulous cleaning to preserve their aesthetic appeal. This is due to their greater reflectivity, which readily reveals dirt, smudges, and scratches. Matte finishes, conversely, tend to conceal minor imperfections more effectively, thereby reducing the frequency of required cleaning interventions. The level of maintenance deemed acceptable should therefore be a primary consideration in the selection process.

Consider, for example, a retail environment. A satin finish might be selected to create a sense of luxury and spaciousness. However, the high foot traffic necessitates daily cleaning to remove scuff marks and maintain the finish’s luster. This might involve damp mopping with a neutral pH cleaner and periodic buffing. A matte finish in the same environment, while potentially less visually striking, could require less frequent cleaning, as it is more forgiving of minor dirt accumulation. The reduced maintenance translates into lower labor costs and less disruption to business operations. Similarly, in residential settings with pets or children, a matte finish may prove more practical due to its ability to hide everyday wear and tear.

Ultimately, the choice between satin and matte floor treatments represents a trade-off between aesthetic preferences and practical considerations. While satin finishes offer a visually appealing sheen, they demand a more rigorous maintenance regime. Matte finishes, on the other hand, prioritize ease of maintenance at the expense of some visual impact. Careful evaluation of the intended use, traffic levels, and available resources is essential for making an informed decision that balances aesthetic goals with long-term maintenance demands. The ease of care with which these finishes can be kept ensures longevity, whether it is a subtle matte or a radiant satin.

4. Slip Resistance

Slip resistance is a critical safety consideration in flooring selection, and its correlation with finish type, specifically matte or satin, warrants careful examination. The coefficient of friction (COF) quantifies slip resistance, with higher values indicating greater traction. While the inherent material properties of the flooring substrate play a significant role, the finish applied significantly modulates the surface texture and, consequently, the slip resistance. The smoother surface characteristic of satin finishes tends to offer less friction compared to the subtly textured surface typically associated with matte finishes. This difference can have tangible consequences, particularly in environments prone to moisture or where vulnerable populations, such as the elderly or individuals with mobility impairments, are present. For example, a bathroom floor finished with a high-sheen sealant presents a greater slip hazard than one treated with a matte sealant, especially when wet. The selection process must therefore prioritize safety and mitigate potential risks associated with reduced traction.

The maintenance regime also influences slip resistance over time. Waxing or polishing satin finishes, while enhancing their aesthetic appeal, can further reduce the COF if not performed correctly, creating a hazardous surface. Conversely, matte finishes often require less intensive maintenance, minimizing the risk of inadvertently reducing slip resistance. Regular cleaning is essential for both types of finishes to remove contaminants that can compromise traction, regardless of the initial COF. Furthermore, the use of anti-slip additives or textured coatings can enhance the slip resistance of any finish, offering an additional layer of safety. These additives are often incorporated directly into the sealant or applied as a separate topcoat, increasing the surface roughness and, consequently, the frictional force.

In summary, the relationship between finish type and slip resistance underscores the importance of a holistic approach to flooring selection. While aesthetic preferences are undoubtedly a factor, safety considerations must take precedence, particularly in environments where the risk of slips and falls is elevated. The initial COF, the impact of maintenance practices, and the potential for incorporating anti-slip measures should all be carefully evaluated to ensure a safe and functional flooring surface. The inherent differences of matte versus satin’s COF become especially relevant in high-risk locations. In conclusion, achieving this equilibrium requires not only an understanding of the material properties of floor treatments, but also a commitment to regular maintenance and the proactive implementation of safety measures.

5. Application

The application process significantly influences the final appearance, durability, and performance of floor finishes, establishing a crucial link between technique and aesthetic outcome. Varying requirements exist for achieving optimal results with satin versus matte sealants, demanding adherence to specific protocols and techniques.

- Surface Preparation and Adhesion

Proper surface preparation is paramount for ensuring adequate adhesion, regardless of the chosen finish. The substrate must be clean, dry, and free of contaminants such as dust, grease, or existing coatings. Sanding or abrading the surface may be necessary to create a suitable profile for mechanical bonding. The specific preparation method can influence the final sheen level; for instance, overly aggressive sanding may diminish the reflectivity of a satin finish, while inadequate preparation can lead to premature failure of either type. Thorough vacuuming and tack-clothing are essential to remove residual debris. A failure to adhere to these protocols can result in inconsistencies in the final application.

- Application Techniques and Layering

The application technique directly impacts the uniformity and thickness of the finish. Applying multiple thin coats, rather than a single thick coat, generally yields superior results, minimizing the risk of runs, drips, or uneven drying. The use of appropriate applicators, such as brushes, rollers, or spray equipment, is critical for achieving a smooth and consistent surface. With satin finishes, care must be taken to avoid over-application, which can result in an undesirable “plasticized” appearance. Matte finishes, while generally more forgiving, still require careful application to ensure uniform coverage and prevent streaking. Each layer should be allowed to dry or cure fully, per manufacturer instructions.

- Environmental Conditions and Curing

Environmental conditions, such as temperature and humidity, play a crucial role in the curing process. Extreme temperatures or high humidity can impede proper drying, leading to clouding, blistering, or adhesion problems. Optimal application conditions typically fall within a specified range, as outlined by the manufacturer. Adequate ventilation is essential to facilitate the evaporation of solvents and prevent the buildup of harmful vapors. Monitoring and controlling environmental conditions is a prerequisite for achieving a durable and aesthetically pleasing finish.

- Post-Application Buffing and Polishing

Post-application buffing or polishing is often employed to refine the surface and enhance the sheen level of satin finishes. This process involves using specialized equipment and pads to smooth out imperfections and create a more uniform reflective surface. However, excessive buffing can damage the finish or alter its intended appearance. Matte finishes generally do not require buffing or polishing, as the desired effect is a non-reflective surface. The decision to buff or polish should be based on the specific recommendations of the finish manufacturer and the desired aesthetic outcome.

These interwoven elements of application significantly influence the final result and efficacy of floor treatments. Whether opting for the refined sheen of satin or the understated elegance of matte, the importance of meticulous preparation, skillful technique, and controlled environmental considerations cannot be overstated. These combined actions establish the stage on how the finishes should look.

6. Appearance

Appearance constitutes a primary differentiator between floor finishes, directly influencing the aesthetic character of a space. The distinction in visual properties between satin and matte floor sealants arises from their differing interactions with light and their resulting surface textures. These variations impact not only the perceived style but also the ability to conceal imperfections and contribute to the overall ambiance of a room.

- Light Reflection and Sheen Level

The degree of light reflection, or sheen level, defines the fundamental visual difference between the two finishes. Satin finishes exhibit a moderate degree of reflectivity, creating a subtle sheen that enhances brightness and provides a smooth, polished appearance. Matte finishes, conversely, minimize light reflection, resulting in a non-glossy surface with a more natural, understated look. The choice depends on the desired level of luminosity and the extent to which reflections are desired.

- Texture and Surface Smoothness

The surface texture contributes significantly to the overall appearance. Satin finishes tend to possess a smoother surface, which enhances light reflection and creates a more refined aesthetic. Matte finishes, with their reduced sheen, often exhibit a slightly more textured surface, which contributes to their ability to conceal minor imperfections and provide a more tactile feel. The selection depends on the desired level of smoothness and the importance of concealing surface flaws.

- Color Saturation and Depth

The finish can influence the perceived color saturation and depth of the flooring material. Satin finishes, due to their reflectivity, can enhance the vibrancy of colors, making them appear richer and more saturated. Matte finishes tend to render colors more accurately, without the added sheen that can sometimes distort hues. The decision depends on the desire to amplify color or maintain its natural appearance.

- Perceived Cleanliness and Maintenance

The choice of finish impacts the perceived cleanliness and the visibility of dirt and imperfections. Satin finishes, due to their reflectivity, can readily reveal dust, smudges, and scratches, necessitating more frequent cleaning to maintain their polished appearance. Matte finishes are more forgiving, concealing minor imperfections and reducing the frequency of required cleaning interventions. The practicality of maintenance should be factored into the selection process.

The considerations outlined above establish the influence of appearance on the selection between floor finishing options. Whether choosing the subtle glow of a light-reflecting surface or one with muted light reflection that minimizes glare, one can achieve a floor treatment that harmonizes the space. Achieving a long-term floor plan that accounts for its desired ambiance, existing environmental conditions, and practical maintenance obligations.

Frequently Asked Questions

This section addresses common inquiries concerning the selection and application of floor finishes, specifically focusing on the differences between satin and matte options.

Question 1: What are the primary differences between satin and matte floor finishes?

The primary difference lies in their sheen level. Satin finishes exhibit moderate light reflection, providing a subtle sheen. Matte finishes minimize light reflection, resulting in a non-glossy appearance.

Question 2: Which finish is more durable, satin or matte?

Durability largely depends on the specific formulation of the finish rather than the sheen level alone. However, matte finishes tend to conceal scratches and imperfections more effectively than satin finishes.

Question 3: What are the maintenance requirements for satin versus matte finishes?

Satin finishes typically require more frequent cleaning to maintain their polished appearance, as they readily reveal dirt and smudges. Matte finishes are more forgiving and require less frequent cleaning.

Question 4: Which finish is more slip-resistant, satin or matte?

Matte finishes generally offer greater slip resistance due to their slightly textured surface. Satin finishes, with their smoother surface, may present a higher risk of slips, particularly when wet.

Question 5: Does the type of flooring material influence the choice between satin and matte finishes?

Yes, the type of flooring material can influence the choice. For example, hardwood floors often benefit from the warmth and depth provided by a satin finish, while concrete floors may achieve a more contemporary look with a matte finish. The material’s inherent properties and the desired aesthetic should be considered.

Question 6: Can anti-slip additives be incorporated into floor finishes?

Yes, anti-slip additives can be incorporated into both satin and matte finishes to enhance slip resistance. These additives increase the surface roughness, thereby improving traction.

Selecting the appropriate floor finish involves careful consideration of factors ranging from aesthetic preferences to practical maintenance demands. An informed decision ensures a durable and visually appealing flooring solution.

The concluding section will provide a comprehensive summary of the key considerations and best practices discussed, along with resources for further exploration of floor finishing techniques and product options.

Concluding Remarks

The preceding discussion has explored the nuanced characteristics of floor finishing options, specifically differentiating between treatments with varying degrees of sheen. Considerations encompassing light reflectivity, durability, maintenance requirements, and slip resistance have been presented. These factors collectively influence the aesthetic and functional performance of flooring installations, emphasizing the importance of informed decision-making. The choice between satin vs matte floor finish is not merely a matter of visual preference but a practical determination with long-term implications.

Ultimately, the selection process should prioritize a comprehensive assessment of the intended use, environmental conditions, and maintenance capabilities. A thoughtful approach, informed by the insights presented herein, will contribute to the creation of durable, safe, and aesthetically pleasing interior spaces. Further research and consultation with industry professionals are encouraged to ensure optimal results and long-term satisfaction with flooring investments.

![Best Water Based Polyurethane Matte Finish [Guide] Best Final Touch: Elevate Your Projects with Professional Finishing Best Water Based Polyurethane Matte Finish [Guide] | Best Final Touch: Elevate Your Projects with Professional Finishing](https://bestfinaltouch.com/wp-content/uploads/2025/12/th-87-300x200.jpg)