Treatments applied to the topmost layer of concrete within a building define the aesthetic and functional properties of the surface. These range from simple sealants offering basic protection to complex multi-layered systems incorporating dyes, stains, and durable topcoats. An example would be applying a polished epoxy coating to a gray slab, yielding a seamless, glossy surface suitable for high-traffic areas.

The selection significantly influences a building’s interior design, durability, and maintenance requirements. Historically, concrete served primarily as a structural element, often concealed beneath other materials. However, its inherent strength, thermal properties, and potential for customization have led to its increasing adoption as a visible and integral part of the architectural design. This evolution offers considerable advantages, including long-term cost savings, design flexibility, and sustainable material use.

The following sections will delve into the various types available, exploring their application techniques, performance characteristics, and suitability for diverse interior spaces. We will also examine the factors influencing selection, including cost considerations, aesthetic preferences, and functional demands.

Guidance on Interior Concrete Floor Treatments

The subsequent recommendations are designed to guide professionals and homeowners in selecting and implementing appropriate surface solutions, ensuring optimal performance and longevity. Careful consideration during the planning and execution phases is paramount.

Tip 1: Surface Preparation is Critical: Prior to applying any coating or treatment, ensure the concrete is clean, dry, and properly profiled. Acid etching, grinding, or shot blasting may be necessary to achieve adequate adhesion. Inadequate preparation will inevitably lead to premature failure of the applied material.

Tip 2: Understand Moisture Vapor Transmission: Concrete is porous and can transmit moisture from the ground. Conduct moisture vapor emission testing to determine if a moisture mitigation system is required before installation. Failure to address moisture issues can result in blistering, delamination, or other surface defects.

Tip 3: Select the Appropriate System for the Application: Consider the intended use of the space, anticipated traffic volume, and exposure to chemicals or other harsh substances. Epoxy coatings are suitable for industrial settings, while polished concrete may be more appropriate for retail environments. A mismatch between the application and the system will compromise durability and aesthetics.

Tip 4: Consider the Coefficient of Friction: Prioritize safety by selecting a texture or additive that provides adequate slip resistance, particularly in areas prone to moisture. A smooth, polished surface can become hazardous when wet, potentially leading to slip-and-fall accidents.

Tip 5: Employ Qualified Installers: The successful application of most treatments requires specialized equipment and expertise. Engaging experienced contractors who are familiar with the specific system being used is essential for achieving optimal results. Amateur installations often result in aesthetic imperfections and structural vulnerabilities.

Tip 6: Invest in Proper Maintenance: Implement a regular cleaning and maintenance schedule to preserve the appearance and extend the lifespan. This may involve the use of neutral pH cleaners, periodic re-sealing, or other specialized treatments. Neglecting maintenance can lead to staining, scratching, and eventual deterioration of the surface.

These guidelines underscore the importance of a comprehensive and informed approach. Diligence in planning, material selection, and execution will yield durable, aesthetically pleasing, and cost-effective surfaces.

The next section will address specific installation techniques and associated best practices.

1. Durability

The durability of interior concrete floor treatments is a paramount consideration, directly impacting the long-term performance and life-cycle cost of the flooring system. Selection of appropriate materials and application techniques are critical to ensuring resistance to wear, impact, and chemical exposure.

- Abrasion Resistance

The ability of a treatment to withstand friction from foot traffic, equipment, and cleaning processes determines its lifespan in high-use areas. Polished concrete, for example, achieves high abrasion resistance through mechanical densification and surface hardening. Conversely, thin coatings may be susceptible to scratching and wear in similar environments, necessitating more frequent maintenance or replacement.

- Impact Resistance

Resistance to impact is critical in industrial settings or areas where heavy objects may be dropped. Epoxy or polyurethane coatings, often formulated with additives to enhance their impact strength, are commonly employed. Untreated or lightly sealed surfaces are vulnerable to chipping and cracking upon impact, leading to costly repairs.

- Chemical Resistance

The capacity to resist degradation from exposure to chemicals, oils, and other corrosive substances is crucial in environments such as garages, workshops, and food processing facilities. Chemically resistant coatings, such as novolac epoxies, are specifically designed to withstand exposure to these substances. Standard sealers may offer limited protection and require regular maintenance to prevent staining and deterioration.

- Moisture Resistance

The ability to resist the intrusion of moisture prevents damage and maintains the integrity of the floor. Moisture resistance is influenced by proper surface preparation, application, and sealing. Inadequate moisture protection will cause blistering, peeling, or mold growth.

These facets of durability collectively determine the overall performance and longevity of a concrete surface. Understanding the specific demands of the environment and selecting a treatment accordingly are essential for maximizing the return on investment and minimizing maintenance requirements.

2. Aesthetics

Aesthetics plays a pivotal role in the selection and implementation of treatments. The appearance of the floor contributes significantly to the overall ambiance of the interior space, influencing the perception of quality, modernity, and style.

- Color and Tone

The chosen color or tone establishes the visual foundation of the space. Integral color pigments mixed into the concrete matrix offer consistent coloration, while stains and dyes provide varied and nuanced effects. Lighter shades can create a sense of openness and brightness, whereas darker tones impart sophistication and warmth. The selection should complement the existing decor and architectural elements.

- Texture and Pattern

The texture and pattern of the surface add tactile and visual interest. Texturing techniques, such as broom finishes, salt finishes, or exposed aggregate, introduce subtle variations and enhance slip resistance. Stenciling, engraving, and decorative overlays provide opportunities to create intricate patterns and personalized designs, transforming a utilitarian surface into a focal point.

- Sheen and Reflectivity

The degree of sheen or reflectivity affects the way light interacts with the surface, influencing the perceived depth and dimension of the space. Polished surfaces exhibit a high degree of reflectivity, creating a sleek, contemporary aesthetic. Matte finishes, conversely, offer a subdued and understated appearance, minimizing glare and highlighting other design elements. Selection depends on the desired level of visual impact and the ambient lighting conditions.

- Seamlessness and Continuity

Seamlessness and continuity contribute to a sense of visual harmony and spaciousness. Treatments, such as epoxy coatings or micro-toppings, create a smooth, monolithic surface, eliminating grout lines and interruptions. This approach enhances the perception of cleanliness and simplifies maintenance, making it well-suited for modern and minimalist designs.

These aesthetic considerations are intrinsically linked to the functional and practical aspects of flooring. An informed decision, balancing visual appeal with performance requirements, leads to a cohesive and enduring design solution. Examples range from retail spaces using vibrant colors and patterns to enhance branding to residential settings employing subtle textures and warm tones to create inviting and comfortable environments.

3. Maintenance

The longevity and aesthetic appeal of treatments are inextricably linked to consistent and appropriate maintenance practices. The absence of proper upkeep precipitates premature deterioration, necessitating costly repairs or replacements. Maintenance is not a supplemental consideration but an integral component, influencing both the visual presentation and the structural integrity of the surface. For instance, a polished surface in a retail environment requires regular dust mopping and occasional damp mopping with a neutral pH cleaner to prevent the accumulation of dirt and grit that can lead to scratching. Conversely, neglecting this regimen results in a dull, scratched surface that detracts from the store’s overall image and necessitates costly refinishing.

Effective maintenance strategies are tailored to the specific type of surface applied and the demands of the environment. Epoxy-coated industrial floors benefit from routine scrubbing with automated equipment and the prompt removal of spills to prevent chemical staining or degradation. In residential settings, sealed or stained surfaces may require periodic reapplication of the sealant to maintain their protective properties. The implementation of entrance mats and area rugs can mitigate the impact of abrasive materials, further prolonging the life of the surface. Adherence to manufacturer-recommended cleaning protocols is critical to avoid the use of harsh chemicals or abrasive cleaning tools that can damage the finish.

In conclusion, proactive maintenance is a decisive factor in preserving the value and performance of surfaces. While initial material and installation costs are significant, the cumulative expense of neglecting maintenance often far exceeds the investment in a consistent cleaning and upkeep program. By understanding the specific maintenance requirements and implementing effective strategies, building owners and facility managers can maximize the lifespan, aesthetic appeal, and overall return on investment.

4. Sustainability

The relationship between sustainability and treatments for internal concrete surfaces is multi-faceted, encompassing material sourcing, energy consumption, indoor environmental quality, and waste reduction. The selection and application of sustainable strategies directly impact a building’s environmental footprint and long-term operational efficiency. Opting for treatments with low volatile organic compound (VOC) emissions improves indoor air quality, minimizing potential health hazards for occupants. Moreover, utilizing recycled content materials, such as fly ash in the concrete mix or recycled glass aggregates in decorative overlays, reduces the demand for virgin resources, promoting a circular economy. The thermal mass properties of concrete inherently contribute to energy efficiency, moderating temperature fluctuations and reducing reliance on heating and cooling systems. An example would be a LEED-certified building utilizing polished concrete with a water-based sealant, showcasing a commitment to low-impact materials and reduced emissions.

Furthering the sustainable agenda involves evaluating the life cycle impact of different surface options. While certain epoxy coatings may offer exceptional durability and chemical resistance, their production and disposal can present environmental challenges. Conversely, mechanically polished concrete, requiring minimal additional materials, represents a lower-impact alternative, provided the polishing equipment is energy-efficient and dust control measures are implemented. Specifying sealants and coatings derived from renewable resources, such as plant-based oils, further minimizes the reliance on petroleum-based products. The longevity of the treatments also plays a significant role; durable options reduce the need for frequent replacements, conserving resources and minimizing waste generation. Considering a comparative life cycle assessment (LCA) is pivotal to select surface options that minimize environmental impact across their entire lifespan, from raw material extraction to end-of-life management.

In conclusion, integrating sustainability principles into the selection and implementation of interior concrete floor surface options is essential for responsible building practices. The combination of environmentally conscious material choices, energy-efficient application techniques, and long-term performance considerations maximizes the environmental benefits and contributes to healthier indoor environments. Addressing the challenges of waste management and VOC emissions while embracing innovative, eco-friendly technologies ensures that concrete surfaces can be both aesthetically pleasing and environmentally responsible.

5. Cost-Effectiveness

Evaluating the long-term financial implications of interior concrete floor treatments necessitates a holistic approach, considering initial installation costs, ongoing maintenance requirements, and the projected lifespan of the chosen system. A surface’s cost-effectiveness is not solely determined by its upfront price but rather by its ability to deliver sustained performance and minimize expenditures over its service life.

- Initial Investment vs. Lifespan

Lower initial costs may be appealing, but systems with shorter lifespans or higher maintenance needs can prove more expensive in the long run. Polished concrete, while requiring a higher upfront investment for grinding and polishing, can offer decades of service with minimal maintenance, potentially surpassing the cost-effectiveness of cheaper alternatives that require frequent replacement or resurfacing. A comparison of initial investment versus total cost of ownership over a 20-year period often reveals the true economic advantage.

- Maintenance Requirements and Costs

The frequency and intensity of maintenance significantly impact the total cost of ownership. Some treatments, such as epoxy coatings in industrial settings, may require specialized cleaning procedures and periodic re-coating to maintain their protective properties, resulting in substantial ongoing expenses. Treatments that are easy to clean and require minimal specialized care offer significant long-term cost savings. A simple cost-benefit analysis should factor in the labor, materials, and equipment required for routine maintenance.

- Energy Efficiency and Thermal Mass

Concrete’s inherent thermal mass can contribute to energy savings by moderating temperature fluctuations within a building, reducing the demand for heating and cooling. Treatments that enhance this thermal performance, such as light-colored sealants that reflect solar heat, can further decrease energy consumption and lower utility bills. Quantifying these energy savings over the life of the building provides a tangible measure of the surface’s cost-effectiveness.

- Repair and Replacement Costs

The susceptibility of a surface to damage and the associated repair or replacement costs are crucial considerations. Treatments with high abrasion and impact resistance minimize the likelihood of damage, reducing the need for costly repairs or replacements. Selecting durable materials and employing proper installation techniques are essential for mitigating these risks. A contingency plan that anticipates potential damage and outlines repair strategies can help manage unforeseen expenses.

Ultimately, determining the cost-effectiveness of interior concrete treatments requires a comprehensive analysis that extends beyond initial price considerations. By factoring in lifespan, maintenance needs, energy efficiency, and potential repair costs, informed decisions can be made that optimize long-term financial value and ensure a durable, aesthetically pleasing, and economically sound flooring solution. Prioritizing sustainability, durability, and easy maintenance contributes to long-term cost savings and environmental benefits.

6. Installation

The effectiveness and longevity of any interior concrete floor system hinge significantly on the quality and precision of the installation process. Improper execution during this phase can compromise the performance characteristics, aesthetic appeal, and long-term durability of the surface. Adherence to industry best practices and manufacturer specifications is, therefore, of paramount importance.

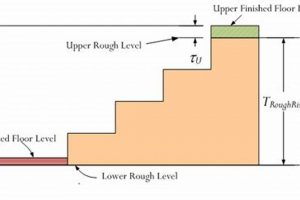

- Surface Preparation Techniques

Proper surface preparation forms the foundation for successful application. This involves cleaning, profiling, and potentially repairing the existing substrate to ensure adequate adhesion and prevent future failures. Acid etching, grinding, shot blasting, and self-leveling underlayments are common techniques employed to achieve a clean, level, and porous surface. Inadequate preparation, such as applying a coating to a contaminated or improperly profiled surface, will inevitably lead to delamination, blistering, and premature wear. For example, failing to remove existing coatings or sealers before applying a new epoxy system will compromise the bond and result in a compromised system.

- Material Mixing and Application

Accurate mixing ratios and proper application techniques are critical for achieving the desired properties of the chosen treatment. Deviations from the manufacturer’s recommended mixing ratios can alter the material’s cure time, strength, and chemical resistance. Uniform application, often achieved using specialized equipment such as squeegees, rollers, or sprayers, ensures consistent thickness and prevents variations in color or texture. Incorrect application techniques, such as applying a coating too thinly or too thickly, can lead to uneven curing, surface imperfections, and compromised performance.

- Environmental Conditions Control

Environmental conditions, including temperature, humidity, and air movement, can significantly impact the curing process and the overall quality of the installation. Maintaining optimal environmental conditions within the specified ranges is essential for achieving proper cross-linking and preventing surface defects. High humidity levels can interfere with the curing of certain coatings, while extreme temperatures can accelerate or retard the curing process. Implementing environmental controls, such as dehumidifiers, heaters, or ventilation systems, can mitigate these risks and ensure a successful outcome. Installation of coatings on concrete that is too cold can also lead to bond failure.

- Curing and Protection

The curing process allows the treatment to fully harden and develop its intended properties. Proper curing requires maintaining specific temperature and humidity levels and protecting the surface from damage during the curing period. Curing compounds or blankets can be used to control moisture loss and promote uniform curing. Premature exposure to traffic, chemicals, or other harsh substances can compromise the curing process and result in surface imperfections or reduced performance. For example, if a concrete floor is subject to heavy traffic prior to curing, it can cause permanent staining or damage and decrease the overall lifespan of the concrete floor.

The preceding facets underscore the importance of meticulous planning, skilled execution, and adherence to manufacturer specifications during the installation phase. A qualified and experienced installation team, equipped with the necessary tools and knowledge, is essential for ensuring that the selected treatment performs as intended and delivers its full potential in terms of durability, aesthetics, and longevity. Proper installation extends from careful cleaning to final curing stages of the chosen system.

Frequently Asked Questions

The following questions address common inquiries and misconceptions concerning interior concrete floor applications. These responses aim to provide clear, concise information to facilitate informed decision-making.

Question 1: What is the typical lifespan of an interior concrete floor finish?

The service life varies considerably based on the type of treatment applied, the level of traffic, and the maintenance practices implemented. Polished systems, when properly maintained, can last for decades. Coatings, depending on the formulation and usage, may require recoating or replacement within 5 to 10 years. Regular maintenance prolongs all surfaces’ durability.

Question 2: Are interior concrete floor treatments susceptible to staining?

The susceptibility to staining is largely dependent on the porosity of the finish and the application of a protective sealer. Unsealed or poorly sealed surfaces are vulnerable to staining from spills and contaminants. Regular sealing or the application of stain-resistant coatings minimizes the risk of permanent discoloration.

Question 3: Is professional installation always necessary for interior concrete floor applications?

While some simpler sealers can be applied by experienced DIYers, more complex applications, such as polished or epoxy systems, generally necessitate professional installation. Proper surface preparation, specialized equipment, and technical expertise are crucial for achieving optimal results and avoiding costly errors. DIY installations can be risky.

Question 4: How does the choice of treatment impact indoor air quality?

Some treatments, particularly solvent-based coatings, can release volatile organic compounds (VOCs) that negatively impact indoor air quality. Selecting low-VOC or water-based options minimizes this risk. Proper ventilation during and after application is also essential to dissipate any residual odors or emissions.

Question 5: Can interior concrete floor finishes be applied over existing flooring materials?

The feasibility of applying concrete treatments over existing flooring depends on the condition and compatibility of the underlying substrate. In most cases, existing materials must be completely removed to ensure proper adhesion and prevent future problems. Direct application is rare but possible, but it usually leads to failures.

Question 6: How does the cost of interior concrete floor treatment compare to other flooring options?

The initial cost can range from moderate to high, depending on the complexity of the system and the level of customization. However, the long-term cost-effectiveness of concrete treatments, particularly those with low maintenance requirements and extended lifespans, often makes them a competitive choice compared to other flooring materials. Compare total cost for an objective understanding.

These FAQs highlight the importance of careful consideration, informed decision-making, and adherence to best practices when selecting and implementing interior concrete floor applications. Consulting with industry professionals is advisable to address project-specific needs and ensure optimal outcomes.

The next section will summarize the key considerations and benefits of interior concrete flooring.

Conclusion

This exploration has underscored the multifaceted nature of interior concrete floor finishes, encompassing durability, aesthetics, maintenance, sustainability, cost-effectiveness, and installation. The appropriate selection and implementation of these surfaces require careful consideration of project-specific needs, performance requirements, and long-term cost implications. The enduring appeal and practical advantages of treated concrete floors lie in their adaptability, resilience, and potential for contributing to both the functional and aesthetic character of interior spaces.

As architectural and design trends evolve, the role of concrete as a versatile and sustainable flooring solution is expected to grow. A commitment to informed decision-making, meticulous installation practices, and proactive maintenance strategies remains paramount in realizing the full potential of interior concrete floor finishes and ensuring their lasting contribution to the built environment. Further research and technological advancements promise to enhance the performance and broaden the application possibilities of these surfaces in the future.