A protective coating formulated with water as its primary solvent, imparting a non-glossy surface, offers a durable and aesthetically pleasing treatment for various substrates. This type of coating provides a layer of protection against scratches, stains, and moisture while minimizing light reflection, resulting in a subtle, low-sheen appearance. Application is common on wood flooring, furniture, and cabinetry where a natural, understated look is desired.

The increasing demand for environmentally conscious products has driven the adoption of this finish type. Its low volatile organic compound (VOC) content contributes to improved air quality, making it a healthier choice for both applicators and end-users. Historically, solvent-based options were prevalent; however, advancements in water-based technology have yielded comparable durability and clarity, coupled with the added benefit of reduced environmental impact. This evolution marks a significant shift towards sustainable finishing practices.

The subsequent sections will delve into application techniques, surface preparation guidelines, optimal drying conditions, and long-term maintenance strategies. Further discussion will cover troubleshooting common issues, assessing cost-effectiveness, and comparing this finish option to alternative protective coatings available on the market.

Application and Maintenance Considerations

The subsequent guidelines serve to optimize the application and extend the lifespan of surfaces treated with this particular finish. Adherence to these practices contributes to a professional outcome and ensures lasting protection.

Tip 1: Surface Preparation is Paramount: Prior to application, thorough sanding is essential to achieve a smooth, uniform substrate. Remove all traces of dust and debris to promote optimal adhesion. Improper preparation compromises the finish’s integrity and aesthetic appeal.

Tip 2: Thin, Even Coats are Preferable: Apply multiple thin coats rather than a single thick layer. This technique minimizes the risk of drips, runs, and uneven drying, resulting in a more consistent and durable finish.

Tip 3: Inter-Coat Abrasion Enhances Adhesion: Lightly abrade the surface between coats using fine-grit sandpaper or a synthetic steel wool. This process creates a mechanical key for subsequent layers, improving inter-coat adhesion and overall durability.

Tip 4: Temperature and Humidity Control are Critical: Maintain consistent temperature and humidity levels within the manufacturer’s recommended range during application and drying. Extremes can negatively impact drying time, film formation, and the final appearance of the finish.

Tip 5: Proper Ventilation Facilitates Drying: Ensure adequate ventilation in the work area to promote efficient evaporation of water and solvents. Insufficient ventilation can prolong drying time and lead to the development of an undesirable odor.

Tip 6: Avoid Excessive Build-Up in Corners and Edges: Exercise caution when applying the finish in corners and along edges to prevent excessive build-up. This accumulation can result in unsightly drips or an uneven sheen.

Tip 7: Regular Cleaning Preserves Appearance: Implement a routine cleaning schedule using a mild, pH-neutral cleaner and a soft cloth. Avoid abrasive cleaners or scouring pads, which can scratch or dull the finish.

By adhering to these application and maintenance guidelines, surfaces will benefit from the protective properties while retaining their desired aesthetic qualities. Proper execution significantly enhances the longevity and overall performance of the finish.

The concluding section will summarize the advantages and disadvantages, providing a balanced perspective to aid informed decision-making.

1. Durability

Durability, in the context of a water-based polyurethane matte finish, is a critical attribute that determines the lifespan and protective capabilities of the coating. It directly influences the resistance of the finished surface to various forms of wear and tear, thereby affecting its overall performance and suitability for specific applications.

- Abrasion Resistance

Abrasion resistance refers to the coating’s ability to withstand friction and surface wear caused by contact with other objects. A durable water-based polyurethane matte finish will exhibit high abrasion resistance, preventing scratches and scuff marks from marring the surface. This is particularly important in high-traffic areas or on furniture that experiences frequent use. For instance, a matte finish on a hardwood floor must resist abrasion from foot traffic and furniture movement to maintain its appearance and protective qualities over time.

- Impact Resistance

Impact resistance describes the coating’s capacity to absorb and dissipate energy from sudden impacts without cracking or chipping. A durable formulation will provide a degree of impact resistance, safeguarding the underlying substrate from damage. This facet is relevant for surfaces prone to accidental impacts, such as table tops or cabinet doors. Consider a dropped object on a table finished with a less durable coating; it may result in unsightly chips or cracks, whereas a more resilient finish would absorb the impact and remain intact.

- Chemical Resistance

Chemical resistance pertains to the coating’s ability to withstand exposure to various chemicals, including household cleaners, solvents, and spills. A durable water-based polyurethane matte finish will resist staining, discoloration, and degradation upon contact with common chemicals. This is particularly important in kitchens and bathrooms where surfaces are frequently exposed to liquids and cleaning agents. For example, a durable finish on kitchen cabinets will prevent damage from grease splatters, water spills, and cleaning solutions, maintaining its appearance and integrity.

- UV Resistance

UV resistance refers to the coating’s ability to resist degradation from exposure to ultraviolet (UV) light. Prolonged exposure to UV radiation can cause fading, yellowing, and weakening of the finish. A durable formulation will incorporate UV absorbers or stabilizers to mitigate these effects. This is crucial for surfaces exposed to direct sunlight, such as outdoor furniture or window trim. A matte finish lacking UV resistance may yellow or fade over time, diminishing its aesthetic appeal and potentially compromising its protective qualities.

These interconnected facets of durability collectively contribute to the overall performance and longevity of a water-based polyurethane matte finish. A robust finish that effectively addresses abrasion, impact, chemical, and UV resistance will provide lasting protection and maintain the aesthetic qualities of the coated surface, ensuring a worthwhile investment.

2. Low VOCs

The connection between low volatile organic compounds (VOCs) and water-based polyurethane matte finishes is fundamental to understanding the product’s environmental and health attributes. Water-based formulations, by their nature, utilize water as the primary solvent, significantly reducing the need for organic solvents that contribute to VOC emissions. This reduction is not merely a byproduct but a core design feature, aligning with increasing regulatory pressure and consumer demand for environmentally responsible coatings. The presence of low VOCs directly translates to improved indoor air quality, minimizing potential health risks associated with solvent-based finishes. For example, applying a low-VOC water-based polyurethane matte finish in a residential setting reduces the off-gassing of harmful chemicals, creating a safer environment for occupants, particularly those with respiratory sensitivities.

The practical significance of understanding this connection extends beyond immediate health benefits. Low VOC content contributes to a smaller carbon footprint during the product’s lifecycle, from manufacturing to disposal. Furthermore, compliance with increasingly stringent environmental regulations is often facilitated by the use of low-VOC coatings. In the context of commercial construction or renovation projects, specifying water-based polyurethane matte finishes demonstrates a commitment to sustainable building practices and can contribute to LEED certification. The application process is also simplified, requiring less stringent ventilation measures compared to solvent-based alternatives, thereby reducing overall project costs and time.

In summary, the low VOC characteristic of water-based polyurethane matte finishes is intrinsically linked to improved air quality, reduced environmental impact, and simplified application. While achieving the desired level of durability and aesthetic appeal with low-VOC formulations presents ongoing formulation challenges, the benefits far outweigh the drawbacks, establishing these finishes as a preferred choice for environmentally conscious applications. The long-term trend indicates a continued shift towards even lower VOC content, driving further innovation in water-based coating technology.

3. Application Ease

Application ease constitutes a significant advantage of water-based polyurethane matte finishes, influencing both project efficiency and end-user satisfaction. The formulation characteristics inherently contribute to simplified application processes compared to traditional solvent-based alternatives. Specifically, water-based polyurethanes exhibit lower viscosity, facilitating smoother spreading and leveling. This property reduces the likelihood of brush marks or uneven coating thicknesses, promoting a more uniform finish with less effort. The extended open time associated with these finishes allows for greater workability, providing ample opportunity to correct imperfections during application. A less experienced user, for instance, can achieve a professional-looking result with a water-based matte polyurethane on a wooden tabletop, minimizing the need for specialized equipment or extensive training.

Furthermore, the cleaning process associated with water-based polyurethanes is significantly streamlined. Brushes, rollers, and spray equipment can be easily cleaned with water, eliminating the need for harsh solvents and reducing disposal costs. This simplifies the overall workflow and minimizes the environmental impact of the finishing process. The absence of strong odors, characteristic of solvent-based finishes, also contributes to a more comfortable working environment, reducing the need for extensive ventilation. Consider a furniture refinishing project undertaken in a confined space; the application of a water-based matte polyurethane poses fewer risks related to inhalation of harmful fumes, making it a more suitable choice for indoor applications.

In summary, the ease of application inherent in water-based polyurethane matte finishes stems from a combination of favorable formulation properties and simplified cleaning procedures. These attributes contribute to increased project efficiency, reduced labor costs, and a more user-friendly experience, making this finish type an attractive option for both professionals and DIY enthusiasts. While proper surface preparation and adherence to manufacturer guidelines remain crucial for achieving optimal results, the inherent application advantages of water-based polyurethanes cannot be understated in the context of overall project success.

4. Aesthetic Appeal

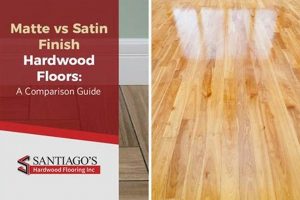

The aesthetic appeal of a surface finished with water-based polyurethane matte coating stems from its capacity to enhance the natural characteristics of the underlying material while imparting a subtle, non-reflective sheen. This balance is achieved by minimizing light scattering across the surface, resulting in a muted, elegant appearance. The reduced gloss level allows the texture and color of the substrate, such as wood grain, to be more readily perceived, contributing to a sense of authenticity and warmth. For instance, a meticulously crafted wooden table finished with this type of coating retains its tactile quality and visual depth, as opposed to being obscured by a high-gloss, reflective surface. The cause-and-effect relationship is direct: the matte finish subtly enhances, rather than overwhelms, the inherent beauty of the material, thereby increasing its aesthetic value.

The importance of aesthetic appeal as a component of water-based polyurethane matte finish is paramount in design applications where visual subtlety and material integrity are prioritized. Consider architectural interiors that feature natural wood elements; a matte finish preserves the wood’s organic qualities, complementing the overall design aesthetic without introducing distracting reflections. Similarly, in furniture design, a matte finish can create a sense of understated luxury, emphasizing the craftsmanship and material quality. The practical significance of this understanding lies in the ability to select appropriate coatings that align with specific design goals, ensuring that the final product not only performs functionally but also meets the desired aesthetic criteria. Specifying a matte finish in applications where a high-gloss appearance would be visually jarring demonstrates an understanding of the nuanced relationship between coating choice and overall design impact.

In summary, the aesthetic appeal of a water-based polyurethane matte finish resides in its ability to enhance natural materials through subtle light diffusion, preserving texture and color. This characteristic is vital in design contexts where understated elegance and material authenticity are paramount. While challenges may arise in achieving consistent matte levels across different substrates, the benefits of improved visual appeal and design coherence outweigh the complexities, solidifying this finish’s role in creating aesthetically pleasing and functionally durable surfaces. The connection to the broader theme of sustainable design is evident, as water-based formulations align with environmental concerns while providing aesthetically desirable outcomes.

5. Surface preparation

The effectiveness of a water-based polyurethane matte finish is inextricably linked to the quality of surface preparation. Inadequate preparation directly compromises adhesion, uniformity, and the long-term performance of the coating. The inherent properties of water-based polyurethanes necessitate a meticulously prepared surface to ensure proper bonding. Contaminants such as dust, grease, or existing finishes impede adhesion, leading to premature peeling or chipping. Similarly, an uneven surface results in an inconsistent matte sheen, detracting from the desired aesthetic. Consider a hardwood floor; if the surface is not properly sanded and cleaned before applying the finish, the polyurethane may not adhere uniformly, resulting in visible imperfections and reduced durability. Therefore, proper surface preparation is not merely a preliminary step but a foundational requirement for achieving a successful and lasting result.

The practical significance of this understanding lies in the implementation of specific preparation techniques tailored to the substrate. For wood surfaces, this involves thorough sanding to remove imperfections and create a smooth, even profile. Chemical cleaning is essential to remove any residual contaminants that may interfere with adhesion. For previously finished surfaces, complete removal of the existing coating is often necessary to ensure compatibility and optimal bonding. Concrete surfaces require a different approach, involving cleaning, etching, and potentially the application of a primer to promote adhesion. In each case, the specific preparation methods must be carefully selected and executed to create a receptive surface for the water-based polyurethane matte finish. Ignoring these protocols often leads to costly rework and a compromised final product.

In summary, surface preparation is a critical determinant of the success of a water-based polyurethane matte finish. Proper preparation creates a foundation for optimal adhesion, uniformity, and durability. While achieving a perfectly prepared surface can be time-consuming and labor-intensive, the benefits in terms of enhanced performance and longevity far outweigh the effort. The challenges associated with surface preparation underscore the need for skilled craftsmanship and meticulous attention to detail, emphasizing its importance as an integral component of the finishing process. This understanding connects to the broader theme of quality assurance, ensuring that the final product meets the desired performance and aesthetic standards.

6. Maintenance

Prolonging the lifespan and preserving the aesthetic qualities of surfaces coated with water-based polyurethane matte finishes necessitates consistent and appropriate maintenance practices. These practices directly impact the coating’s resistance to wear, staining, and other forms of degradation. Therefore, understanding and implementing proper maintenance protocols is crucial for maximizing the investment in this type of finish.

- Regular Cleaning Protocols

The establishment of a routine cleaning schedule forms the cornerstone of effective maintenance. This involves the use of pH-neutral cleaners specifically designed for polyurethane finishes. Abrasive cleaners and harsh chemicals should be avoided, as they can damage the matte surface and diminish its protective properties. For example, a weekly cleaning regimen for a water-based polyurethane matte finished hardwood floor, using a microfiber mop and a recommended cleaner, prevents the build-up of dirt and grime, which can lead to scratching and dulling of the finish over time.

- Spill Management and Stain Prevention

Prompt removal of spills is essential to prevent staining and potential damage to the finish. Liquids, particularly those containing pigments or acidic substances, should be wiped up immediately with a clean, absorbent cloth. Prolonged exposure to spills can lead to discoloration or etching of the matte surface. Consider a kitchen countertop finished with a water-based polyurethane matte coating; immediate cleanup of spills, such as red wine or coffee, minimizes the risk of permanent staining, preserving the finish’s appearance and protective barrier.

- Scratch Mitigation and Repair

While water-based polyurethane matte finishes offer a degree of scratch resistance, preventive measures should be taken to minimize the occurrence of scratches. The use of furniture pads under heavy objects and avoiding dragging items across the surface can significantly reduce the risk of scratches. Minor scratches can often be addressed with specialized touch-up kits designed for polyurethane finishes. For example, strategically placed felt pads beneath chair legs on a water-based polyurethane matte finished dining table prevent scratches during regular use, extending the life of the finish and maintaining its aesthetic appeal.

- Environmental Control Considerations

Maintaining stable environmental conditions, particularly humidity levels, contributes to the longevity of the finish. Excessive humidity can cause wood substrates to expand and contract, potentially leading to cracking or peeling of the polyurethane coating. In environments with fluctuating humidity, the use of humidifiers or dehumidifiers can help stabilize moisture levels. A museum display case finished with a water-based polyurethane matte coating, where temperature and humidity are carefully controlled, ensures the long-term preservation of both the artifact and the finish, preventing environmental degradation and maintaining a consistent aesthetic.

These interconnected facets of maintenance underscore the importance of a proactive and informed approach to preserving surfaces finished with water-based polyurethane matte coatings. Consistent cleaning, prompt spill management, scratch prevention, and environmental control collectively contribute to the extended lifespan and sustained aesthetic qualities of the finish. Neglecting these maintenance protocols can lead to premature degradation, diminishing the value and performance of the coated surface. These measures helps in ensuring that the purpose to use the keyword “water based polyurethane matte finish” is served for long term.

Frequently Asked Questions

The following section addresses common inquiries and concerns regarding water-based polyurethane matte finishes, providing informative answers based on industry standards and best practices.

Question 1: Is a water-based polyurethane matte finish as durable as a solvent-based alternative?

Modern water-based formulations offer comparable durability to solvent-based polyurethanes for many applications. The specific durability depends on the formulation, number of coats applied, and the preparation of the substrate. Researching product-specific data sheets and consulting with professionals is recommended to determine suitability for high-wear environments.

Question 2: What is the typical drying time for a water-based polyurethane matte finish?

Drying times vary depending on environmental conditions (temperature and humidity), the thickness of the applied coat, and the specific product formulation. Generally, recoating is possible within 2-4 hours, and full cure is achieved within 7-14 days. Consulting the manufacturer’s guidelines is crucial for accurate drying time information.

Question 3: Can a water-based polyurethane matte finish be applied over an existing oil-based finish?

Direct application over an existing oil-based finish is generally not recommended due to potential adhesion issues. Proper surface preparation, including thorough sanding and the application of a compatible primer, is necessary to ensure a successful bond. Testing a small, inconspicuous area is advisable before proceeding with the entire project.

Question 4: How is a water-based polyurethane matte finish cleaned and maintained?

Routine cleaning involves using a damp cloth with a mild, pH-neutral cleaner. Abrasive cleaners or scouring pads should be avoided, as they can damage the matte surface. Promptly wiping up spills prevents staining. Periodic reapplication of a maintenance coat may be necessary to refresh the finish and enhance its protective properties.

Question 5: Does a water-based polyurethane matte finish offer UV protection?

Some water-based polyurethane matte finishes incorporate UV absorbers to mitigate the effects of sunlight exposure. However, not all formulations provide the same level of UV protection. For surfaces exposed to direct sunlight, selecting a product specifically designed for UV resistance is recommended to prevent fading and discoloration.

Question 6: What are the volatile organic compound (VOC) levels typically found in a water-based polyurethane matte finish?

Water-based polyurethane matte finishes generally exhibit lower VOC levels compared to solvent-based alternatives. VOC content can vary depending on the specific formulation and regulatory standards. Consulting the product’s technical data sheet or safety data sheet (SDS) provides accurate information regarding VOC levels.

These FAQs provide a foundation for understanding water-based polyurethane matte finishes. Additional research and consultation with industry experts are encouraged for specific applications and unique project requirements.

The subsequent section will explore specific case studies and real-world applications of this finish type, further illustrating its benefits and limitations.

Conclusion

The preceding analysis has explored the various facets of water-based polyurethane matte finish, emphasizing its durability, low volatile organic compound content, ease of application, aesthetic properties, the crucial role of surface preparation, and the necessity of consistent maintenance. This type of finish presents a viable option for diverse applications, offering a balance between performance and environmental responsibility.

The information provided serves as a foundation for informed decision-making. Further investigation into specific product formulations and project requirements is encouraged to ensure optimal results. The adoption of sustainable finishing practices, exemplified by water-based polyurethane matte finish, reflects a commitment to responsible resource management and long-term durability in construction and design.