A protective coating applied to wooden surfaces, it creates a durable, clear layer. The composition typically includes synthetic resins that harden upon application, offering resistance against scratches, stains, and wear. This sealant is frequently used in residential and commercial settings to preserve and enhance the appearance of timber flooring.

The application of this type of coating provides significant advantages, including extended lifespan of the floor, simplified maintenance, and heightened resistance to moisture penetration. Historically, traditional finishes were less resilient, necessitating more frequent reapplication. Modern formulations offer improved durability and longevity, reducing the need for regular upkeep.

The subsequent discussion will delve into the different types available, explore proper application techniques, and outline essential maintenance strategies for ensuring long-term preservation. Considerations regarding environmental impact and safety precautions will also be addressed.

Application and Maintenance Guidelines

Effective application and diligent maintenance are crucial for realizing the full potential of this protective sealant. Adherence to the following guidelines will contribute to a prolonged lifespan and sustained aesthetic appeal.

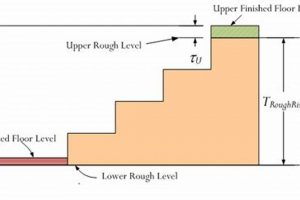

Tip 1: Surface Preparation. Ensure the substrate is thoroughly cleaned and properly sanded. Residual dirt, debris, or existing coatings can compromise adhesion and result in an uneven finish.

Tip 2: Selection of Appropriate Product. Different formulations exist, each designed for specific applications and traffic levels. Consider the intended use of the space and select a product accordingly (e.g., water-based for low-VOC environments, oil-based for enhanced durability).

Tip 3: Application Technique. Apply thin, even coats using a high-quality applicator. Avoid excessive build-up, which can lead to bubbling or prolonged drying times. Multiple thin coats are preferable to a single thick coat.

Tip 4: Proper Drying Time. Allow sufficient drying time between coats, as specified by the manufacturer. Premature application of subsequent coats can result in a compromised and potentially cloudy final result.

Tip 5: Ventilation. Ensure adequate ventilation during application and drying. This minimizes the accumulation of potentially harmful vapors and promotes uniform drying.

Tip 6: Regular Cleaning. Implement a routine cleaning regimen using a pH-neutral cleaner designed for finished wooden floors. Abrasive cleaners can damage the coating and dull the finish.

Tip 7: Preventative Measures. Employ preventative measures to minimize wear and tear. Use area rugs in high-traffic zones, apply felt pads to furniture legs, and promptly clean up spills.

By adhering to these guidelines, the benefits of this protective layer will be fully realized, contributing to the longevity and aesthetic appeal of the floor.

The subsequent sections will explore specific product recommendations and address common troubleshooting issues encountered during the application and maintenance process.

1. Durability

Durability represents a critical performance attribute when evaluating coatings for timber surfaces. The capacity to withstand wear, abrasion, and impact directly correlates with the lifespan and aesthetic appeal of the treated flooring. Selecting a product with appropriate resilience is essential for preserving the integrity of the wood beneath.

- Abrasion Resistance

This property indicates the coating’s ability to withstand surface wear caused by foot traffic, furniture movement, and cleaning activities. Products with high abrasion resistance ratings, often measured using the Taber Abraser test, exhibit greater longevity in high-traffic environments. An example is the selection of a polyurethane coating for a commercial retail space, where constant foot traffic necessitates a high level of abrasion resistance.

- Impact Resistance

The coating’s capacity to withstand sudden impacts without cracking, chipping, or delaminating is crucial, particularly in areas prone to accidental drops or heavy objects. Impact resistance is often assessed using tests that measure the force required to cause damage. A gym floor, for example, benefits from a coating with high impact resistance to withstand the repeated impact of dropped weights and athletic activities.

- Chemical Resistance

The ability to resist damage from common household chemicals, spills, and cleaning agents is vital for maintaining the coating’s appearance and structural integrity. Chemical resistance testing involves exposing the coating to various substances and assessing the degree of discoloration, softening, or degradation. Kitchen floors, for instance, require a coating with high chemical resistance to withstand spills of oils, acids, and cleaning solutions.

- Scratch Resistance

This measures the coating’s ability to resist scratches from sharp objects or abrasive materials. Coatings with enhanced scratch resistance maintain a smoother, more aesthetically pleasing surface over time. Consider a home with pets; a coating with high scratch resistance will better withstand the wear and tear from pet claws.

These facets collectively contribute to the overall durability. Selecting a product with appropriate levels of abrasion, impact, chemical, and scratch resistance, based on the anticipated wear and tear, ensures the long-term preservation of both the protective layer and the wooden flooring beneath.

2. Appearance

The aesthetic quality of a wood floor is significantly influenced by the type and application of the protective sealant. The finish not only protects the wood but also dictates its visual characteristics, contributing to the overall ambiance of the space.

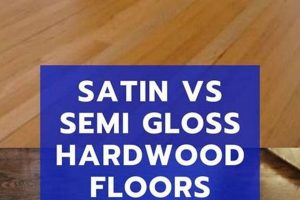

- Sheen Level

The level of gloss or reflectance significantly impacts the perceived brightness and formality of a room. Options range from matte, which offers a low-luster, natural look, to high-gloss, which provides a highly reflective, polished appearance. For example, a matte finish might be preferred in a rustic-themed living room, while a high-gloss finish could be chosen for a modern, formal dining area. The selection should align with the intended style and use of the space.

- Clarity and Color Enhancement

Some formulations are designed to enhance the natural color and grain of the wood, while others may impart a subtle tint or color. Clear finishes allow the wood’s inherent beauty to shine through, while tinted finishes can add warmth or depth. Consider the choice between a clear finish to showcase the natural tones of maple versus a slightly ambered finish to enrich the color of oak. The choice depends on the desired aesthetic and the existing color palette of the room.

- Smoothness and Texture

The application technique and the type of product used can influence the final smoothness and texture of the surface. Properly applied coats result in a smooth, even surface, while imperfections in the application can lead to a textured or uneven appearance. For instance, inadequate sanding between coats can create a rough texture, while proper application yields a smooth, glass-like surface. The final texture contributes to the tactile and visual experience of the floor.

- Resistance to Yellowing

Some finishes are prone to yellowing over time, particularly when exposed to sunlight. This can alter the original color of the wood and detract from its appearance. Formulations with UV inhibitors offer greater resistance to yellowing, preserving the original color for a longer period. For example, a water-based finish with UV protection would be ideal for a room with large windows and direct sunlight exposure. This ensures the floor maintains its intended color and appearance over its lifespan.

The interplay of sheen, clarity, texture, and resistance to yellowing collectively determines the aesthetic impact. Careful consideration of these factors ensures that the chosen finish enhances the wood’s natural beauty and complements the overall design of the space, reinforcing the importance of selecting the appropriate wood floor urethane finish.

3. Application

The effective application of a protective coating is paramount in realizing its intended performance characteristics. Improper application can compromise the finish’s durability, appearance, and longevity, regardless of the product’s inherent qualities. The subsequent points outline critical facets of the application process.

- Surface Preparation

Prior to application, thorough surface preparation is indispensable. This includes the removal of existing coatings, sanding to create a smooth and even substrate, and meticulous cleaning to eliminate dust, debris, and contaminants. Inadequate surface preparation can lead to adhesion failures, uneven finish, and premature wear. For instance, applying over a waxed surface will impede proper bonding, resulting in peeling and chipping. Proper preparation ensures optimal adhesion and a uniform appearance.

- Environmental Conditions

The ambient temperature and humidity levels significantly influence the curing process and the final finish quality. Application outside the recommended temperature range can result in improper drying, bubbling, and other defects. High humidity can prolong drying times and affect the clarity of the finish. Ideally, application should occur within the manufacturer’s specified temperature and humidity ranges. For example, applying a water-based product in excessively cold temperatures can prevent proper film formation, leading to a compromised finish.

- Application Techniques

The chosen method of application, such as brushing, rolling, or spraying, can impact the final result. Each technique requires specific skill and equipment to achieve a uniform and defect-free coating. Brushing may leave brush marks if not performed correctly, while rolling can introduce air bubbles. Spraying, although capable of producing a smooth finish, requires proper ventilation and safety precautions. Selecting the appropriate application method and employing proper techniques are essential for achieving the desired appearance and performance characteristics.

- Number of Coats and Drying Time

Applying the correct number of coats and allowing sufficient drying time between coats are critical for achieving optimal protection and appearance. Insufficient coats may result in inadequate film thickness and reduced durability, while excessive coats can lead to cracking and peeling. Premature application of subsequent coats can trap solvents and create a cloudy finish. Adhering to the manufacturer’s recommendations regarding the number of coats and drying times is crucial for realizing the coating’s full potential.

These facets underscore the importance of meticulous adherence to established protocols during the application process. Failure to address these aspects can compromise the benefits of the floor’s protective covering, resulting in reduced lifespan and increased maintenance requirements. Skilled application is as important as the intrinsic quality of the coating product itself.

4. Maintenance

Sustained performance of wood flooring protected with a urethane finish is directly contingent upon appropriate and consistent maintenance practices. These practices preserve the integrity of the coating, thereby extending the lifespan and aesthetic appeal of the floor.

- Regular Cleaning Protocols

Consistent removal of dirt, dust, and debris through sweeping, vacuuming, or damp mopping is essential. Abrasive particles can scratch the surface of the coating, diminishing its protective properties and appearance. The frequency of cleaning should be commensurate with the traffic volume and potential for soiling. For example, high-traffic areas like entryways may require daily cleaning, while less frequented rooms can be maintained on a weekly basis. The use of pH-neutral cleaners specifically designed for wood floors is recommended to avoid damaging the finish.

- Spill Management

Prompt attention to spills is crucial to prevent staining and water damage. Liquids, particularly those containing acidic or alkaline substances, can penetrate the coating and compromise its protective barrier. Immediate blotting of spills with a clean, absorbent cloth minimizes the risk of long-term damage. For instance, spills of red wine or coffee should be addressed immediately to prevent permanent discoloration. This proactive approach safeguards the finish and underlying wood.

- Protection Against Scratches and Dents

Implementing preventative measures to minimize scratches and dents is essential for preserving the floor’s appearance and structural integrity. Felt pads affixed to furniture legs reduce the risk of scratching during movement. Area rugs placed in high-traffic zones provide an additional layer of protection against wear and tear. Avoiding the use of shoes with hard soles or pointed heels can also minimize the potential for damage. These precautions contribute to the long-term preservation of the finish and the underlying wood.

- Periodic Recoating

Over time, even with diligent maintenance, the urethane finish will experience wear and tear. Periodic recoating, typically every 3-7 years depending on traffic and usage, rejuvenates the protective layer and restores the floor’s appearance. This process involves lightly sanding the existing finish to create a bonding surface and applying a fresh coat. Recoating extends the lifespan of the floor and prevents the need for more extensive and costly refinishing in the future.

These facets of maintenance, when implemented consistently, ensure the long-term performance and aesthetic appeal of timber flooring protected with a urethane-based finish. The investment in diligent maintenance practices is a critical component of preserving the floor’s value and minimizing the need for costly repairs or replacements.

5. Cost

The economic considerations associated with “wood floor urethane finish” encompass material expenses, labor costs, and long-term maintenance investments. Initial material costs vary based on the type of urethane product selected, ranging from less expensive, solvent-based options to more costly, low-VOC, water-based alternatives. Labor costs are influenced by the complexity of the application process, the size of the area being treated, and the skill level required for surface preparation and application. For instance, a DIY application may reduce initial labor costs but could incur higher long-term costs due to potential application errors leading to premature wear or the need for professional remediation.

Long-term cost implications are tied to the durability and maintenance requirements of the chosen urethane finish. More durable products, while potentially carrying a higher initial price tag, can translate into reduced maintenance expenses and extended intervals between recoating or refinishing. A commercial space opting for a high-traffic, high-solids urethane may experience lower annual maintenance costs compared to a similar space utilizing a less resilient finish that requires more frequent maintenance and eventual replacement. Conversely, lower initial costs may be offset by increased maintenance demands, reduced lifespan, and potential repair expenses.

Understanding the interplay between initial investment and long-term operational costs is crucial for making informed decisions regarding wood floor protection. A comprehensive cost analysis, considering material expenses, labor, maintenance, and lifespan, enables informed budgeting and selection of a product that aligns with both financial constraints and performance expectations. Failing to account for long-term costs associated with cheaper alternatives can result in greater overall expenses compared to a higher-quality, more durable finish with a longer lifespan and reduced maintenance needs.

6. Longevity

The lifespan of timber flooring is intrinsically linked to the protective qualities afforded by its surface coating. The judicious selection and proper application of a suitable sealant directly influence the floor’s resistance to wear, abrasion, moisture penetration, and chemical exposure. Consequently, the chosen coating, and, critically, its capacity to maintain its protective properties over time, dictates the flooring’s ultimate longevity. For instance, a floor coated with a high-quality, multi-component system in a high-traffic retail environment is likely to exhibit superior resistance to wear compared to a floor treated with a single-component, lower-solids product, thereby extending the former’s serviceable life.

Various factors contribute to the long-term performance and, hence, the extended lifespan provided by this sealant. The inherent chemical composition of the coating, its resistance to UV degradation, the quality of its application, and adherence to proper maintenance protocols each play a critical role. Inadequate surface preparation, for example, can compromise adhesion and lead to premature coating failure, thereby shortening the floor’s lifespan. Similarly, exposure to direct sunlight without adequate UV inhibitors in the coating can result in yellowing, embrittlement, and subsequent cracking, also diminishing the floor’s longevity. Practical applications demonstrate that diligent maintenance, including regular cleaning and prompt spill management, significantly contributes to extending the floor’s usable life.

The relationship between coating and flooring lifespan highlights the economic and practical significance of informed decision-making. Selecting a more durable, albeit potentially more expensive, product can result in reduced long-term costs associated with repair, replacement, and maintenance. Understanding the factors that influence this product’s long-term performance, coupled with adherence to best-practice application and maintenance procedures, is crucial for maximizing the investment in timber flooring and ensuring its prolonged structural integrity and aesthetic appeal. The primary challenge lies in balancing initial cost considerations with the long-term benefits of enhanced durability and extended service life, a decision that requires careful evaluation of the specific environmental conditions and usage patterns to which the floor will be subjected.

Frequently Asked Questions

The following questions address common concerns and misconceptions surrounding this protective floor coating. The provided answers aim to clarify key aspects relevant to selection, application, and maintenance.

Question 1: What is the typical lifespan of a wood floor urethane finish?

Lifespan varies significantly based on the type of product applied, traffic volume, and maintenance practices. Generally, a properly applied and maintained finish can last between 3 and 10 years before requiring recoating. High-traffic areas may necessitate more frequent attention.

Question 2: Are all urethane finishes the same?

No. Significant differences exist between oil-based and water-based formulations. Oil-based options typically offer greater durability but release higher levels of volatile organic compounds (VOCs). Water-based options have lower VOCs but may require more coats to achieve comparable durability.

Question 3: Can a urethane finish be applied over an existing finish?

Generally, the existing surface must be properly prepared. This often entails sanding to create a suitable bonding surface. Compatibility between the existing and new finish should be verified to prevent adhesion problems or other adverse reactions.

Question 4: Is a professional application necessary?

While DIY application is possible, professional application is recommended, particularly for large or complex projects. Professionals possess the expertise and equipment to ensure proper surface preparation, uniform application, and optimal curing conditions, thereby maximizing the finish’s performance and longevity.

Question 5: What cleaning products are appropriate for urethane-finished wood floors?

Only pH-neutral cleaners specifically designed for wood floors are recommended. Abrasive cleaners, solvents, and oil-based soaps can damage the finish and should be avoided. Damp mopping with a microfiber mop and appropriate cleaner is generally sufficient for routine maintenance.

Question 6: How can scratches and dents be minimized on a urethane-finished floor?

Preventative measures are crucial. Felt pads should be applied to furniture legs. Area rugs should be placed in high-traffic areas. Avoid wearing shoes with hard soles or pointed heels. Promptly clean up spills to prevent staining or water damage.

In summary, the performance and longevity of wood flooring protected with this sealant depends on informed product selection, skilled application, and consistent maintenance.

The following section will address troubleshooting common issues encountered with this protective layer.

Conclusion

The preceding exploration of “wood floor urethane finish” has elucidated its pivotal role in safeguarding and enhancing timber flooring. Critical factors influencing its performance include product selection, application methodology, and consistent maintenance practices. Neglecting any of these elements can compromise the investment and reduce the flooring’s lifespan.

Ultimately, informed decision-making, coupled with meticulous execution, is paramount. A comprehensive understanding of this protective layer’s properties and limitations allows for the realization of its full potential, ensuring long-term preservation and sustained aesthetic appeal of the underlying wooden surface. Therefore, prioritize knowledge and diligence in all phases of implementation to maximize the benefits afforded by “wood floor urethane finish”.