An applied coating replicates the aesthetic of a copper alloy comprised primarily of copper, often with tin as the main additive. This surface treatment, typically applied to a substrate like steel or aluminum, imparts a visual resemblance to the original alloy. For example, a steel door could be treated to simulate the coloration and texture of the original material.

The use of this surface treatment provides a cost-effective alternative to utilizing the solid alloy. It offers the desired appearance while potentially reducing material costs and weight. Historically, the genuine alloy has been valued for its durability and corrosion resistance. This imitation offers a similar visual appeal, often at a lower cost point, suitable for decorative and functional applications.

Subsequent sections will explore the specific application methods, durability characteristics, and comparative advantages of this type of coating across various industries and products. Furthermore, the different levels of quality and maintenance are discussed.

Maximizing the Longevity and Appearance

Optimal utilization requires understanding of its properties and appropriate care to preserve its intended aesthetic and performance characteristics.

Tip 1: Regular Cleaning: Implement a routine cleaning schedule using mild soap and water. Avoid abrasive cleaners which can scratch or dull the surface, diminishing its visual appeal. Residue buildup can detract from the intended visual effect.

Tip 2: Avoid Harsh Chemicals: Exposure to strong solvents, acids, or alkaline solutions can damage the coating. These substances may cause discoloration, etching, or even complete removal of the finish. Always consult the product’s care instructions.

Tip 3: Protect from Direct Sunlight: Prolonged exposure to ultraviolet (UV) radiation can lead to fading or chalking of the surface treatment. Where possible, shield items from constant, direct sunlight to preserve the color and luster.

Tip 4: Apply Protective Wax: A high-quality, non-abrasive wax can provide a protective barrier against environmental factors. This wax layer helps to repel water, prevent oxidation, and enhance the shine of the surface. Apply wax periodically according to product recommendations.

Tip 5: Promptly Address Scratches: Minor scratches can be repaired with touch-up paints specifically formulated for these finishes. Applying these promptly will prevent corrosion from starting beneath the marred surface. Follow the manufacturer’s directions precisely for optimal results.

Tip 6: Consider Indoor vs. Outdoor Applications: Exterior applications demand more frequent maintenance due to increased exposure to the elements. Interior applications generally require less frequent attention, but the same care principles still apply.

Consistent adherence to these tips ensures the sustained aesthetic appeal, maintains protection, and extends the life. Proper care preserves value by preventing premature degradation and failure.

The subsequent discussion examines the factors affecting the selection for different applications, highlighting the considerations in making an informed purchase.

1. Visual aesthetic replication

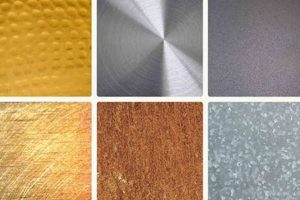

The capacity to emulate the visual characteristics of a genuine copper-tin alloy through alternative materials represents a core function. This replication is not merely superficial; it involves capturing the nuances of color, texture, and sheen inherent to the original material.

- Color Matching Precision

Achieving accurate color matching is paramount. This involves employing pigments and dyes that mimic the specific hues and tones characteristic of the genuine alloy at various stages of oxidation. Improper color matching results in a product that lacks authenticity and visual appeal.

- Textural Reproduction

The texture plays a critical role in the overall visual perception. Application techniques must create a surface that replicates the feel and appearance of aged or polished bronze. This can involve specialized coatings and surface treatments to simulate the subtle imperfections and variations found in natural materials.

- Sheen and Luster Simulation

The characteristic sheen and luster are achieved through specific coating formulations and application methods. Controlling the reflectivity of the applied surface is essential to mimic how light interacts with real material, whether polished to a high gloss or aged to a matte finish.

- Patina Development Mimicry

One of the most compelling aspects is the natural patina, a gradual process of oxidation that imparts a unique character. Sophisticated finishes can emulate this effect, creating a sense of age and history. This mimicry may involve layering different coatings or introducing chemical treatments to simulate the oxidation process.

The successful visual reproduction allows for the application of alloy-like aesthetics across a broader range of products and industries. This enables manufacturers to offer the desired aesthetic at a reduced cost and with enhanced material properties, thereby expanding the accessibility and versatility of the distinctive material appearance.

2. Corrosion resistance simulation

Surface treatments designed to replicate the appearance of copper-tin alloys often incorporate elements intended to emulate the alloy’s natural resistance to corrosion. While the underlying material may not possess the inherent properties of the solid alloy, the applied finish aims to provide a degree of protection against environmental degradation.

- Barrier Coatings

The primary mechanism for corrosion resistance simulation is the application of a barrier coating. This layer acts as a physical impediment, preventing moisture, pollutants, and other corrosive agents from reaching the substrate material. The effectiveness of this barrier depends on its integrity, thickness, and chemical composition. Real-world examples include protective coatings applied to steel railings or outdoor furniture to prevent rust. Any compromise in this barrier can lead to localized corrosion and eventual failure.

- Sacrificial Anode Effect

Some coatings incorporate metals that act as sacrificial anodes. These metals are more reactive than the underlying substrate and corrode preferentially, thereby protecting the base material. This principle is analogous to the use of zinc coatings on steel (galvanization). While a finish replicating the appearance of the copper-tin alloy will not be a “true” sacrificial coating as zinc on steel is, the principles are still relevant.

- Passivation Layer Mimicry

True copper-tin alloys develop a natural passivation layer, a thin, adherent oxide film that inhibits further corrosion. Some surface treatments attempt to mimic this effect by incorporating chemicals that promote the formation of a similar protective layer on the finish itself. This imitation is particularly relevant in environments where the treated item is exposed to atmospheric elements, such as architectural details or outdoor sculptures.

- Coating Impermeability Enhancement

The inclusion of additives and specialized polymers can enhance the impermeability of the applied coating. These additives reduce the porosity of the finish, making it more difficult for corrosive substances to penetrate and attack the substrate. Examples of this approach are prevalent in marine applications, where items are constantly exposed to seawater and salt spray.

The effectiveness of corrosion resistance simulation is contingent upon proper application techniques and the quality of the materials used. While these methods can provide a significant degree of protection, they do not necessarily replicate the long-term corrosion resistance inherent to solid copper-tin alloys. Therefore, careful consideration of the intended application environment and maintenance requirements is crucial to ensure the longevity and performance of items utilizing surface treatments.

3. Application substrate variations

The selection of a suitable substrate significantly influences the adhesion, durability, and overall aesthetic of coatings designed to replicate copper-tin alloys. Different materials exhibit varying surface properties, thermal expansion coefficients, and chemical reactivities, necessitating tailored application techniques and coating formulations. For instance, steel substrates may require pretreatment to prevent corrosion beneath the applied surface, while aluminum substrates may need surface preparation to enhance coating adhesion. Improper substrate selection or preparation can lead to premature coating failure, compromising both the appearance and protective functionality.

Consider architectural applications. Coatings on steel railings demand formulations with flexibility to accommodate thermal expansion and contraction. Coatings on aluminum panels require enhanced adhesion to resist delamination under environmental stress. Wood substrates, if employed, necessitate sealing and priming to prevent moisture absorption and ensure uniform coating application. The variance in these requirements directly impacts the long-term performance and visual integrity. An example would be a steel door utilizing the coating, but if the steel wasn’t properly treated before application the coating will begin to peel.

In summary, understanding the specific characteristics of the substrate material is paramount to achieving a durable and visually appealing finish. Appropriate substrate preparation, tailored coating formulations, and meticulous application techniques are essential for maximizing the lifespan and performance. Ignoring these variations leads to suboptimal results, increased maintenance costs, and a diminished aesthetic. Subsequent analysis will further delve into specific preparation techniques for common substrate materials.

4. Cost-effectiveness benefits

The economic advantages associated with applied coatings that mimic the aesthetic of copper-tin alloys stem from several factors, most notably material cost reduction and simplified manufacturing processes. Utilizing base metals such as steel or aluminum, which are generally less expensive than solid copper-tin alloys, significantly lowers material expenses. Furthermore, the application process, often involving spraying or powder coating, is typically more efficient and less labor-intensive than casting, machining, or forming solid components. This efficiency translates to reduced manufacturing costs and quicker production cycles. The net effect is a finished product that achieves a similar visual appeal at a lower overall price point.

Consider architectural hardware, such as door handles or light fixtures. Producing these items from solid copper-tin alloys would necessitate substantial material expenditures and intricate manufacturing techniques. By contrast, employing steel or zinc substrates with an applied coating drastically reduces material costs and allows for simpler, high-volume production methods. The resulting hardware maintains a similar visual appearance to that of the solid alloy, fulfilling the aesthetic requirements without incurring the higher costs associated with traditional manufacturing processes. This approach also allows for greater design flexibility, as the coating can be applied to complex shapes and geometries more easily than the solid alloy can be formed.

In summary, the cost-effectiveness stems from the combined benefits of reduced material expenses, streamlined manufacturing processes, and enhanced design flexibility. While the inherent properties of solid copper-tin alloys, such as superior corrosion resistance, may not be fully replicated, the cost savings often outweigh these considerations, particularly in applications where aesthetic appeal is the primary concern. The trade-off between cost and performance is a key factor driving the widespread adoption of this technique across various industries, from construction and automotive to consumer goods and electronics.

5. Maintenance requirements

Preservation of coatings imitating copper-tin alloys necessitates adherence to specific maintenance protocols to ensure sustained aesthetic quality and prolonged lifespan. The frequency and intensity of these protocols are contingent upon the environmental conditions to which the coating is exposed, the nature of the substrate material, and the specific formulation of the applied finish. Neglecting appropriate maintenance can lead to premature degradation, diminished visual appeal, and compromised protective function.

- Regular Cleaning Regimen

Establishment of a routine cleaning schedule is paramount in preventing the accumulation of dirt, grime, and other contaminants that can dull the surface. Mild, non-abrasive detergents and soft cloths should be employed to avoid scratching or damaging the finish. The frequency of cleaning should be adjusted based on the level of exposure to environmental pollutants; for instance, exterior applications in urban environments may require more frequent cleaning than interior applications in controlled environments. Failure to maintain a regular cleaning regimen results in a buildup of debris that can accelerate corrosion and detract from the intended aesthetic.

- Protective Wax Application

The periodic application of a protective wax coating serves to create a barrier against moisture, ultraviolet radiation, and other environmental factors that can contribute to the degradation. The wax should be specifically formulated for use on metal finishes and applied according to the manufacturer’s instructions. This protective layer helps to preserve the luster and color of the coating, extending its lifespan. Neglecting wax application allows environmental elements to directly impact the finish, leading to fading, oxidation, and eventual deterioration.

- Prompt Scratch Repair

Any scratches or abrasions that penetrate the coating should be addressed promptly to prevent corrosion from spreading to the underlying substrate. Touch-up paints or repair kits specifically designed for metal finishes can be used to conceal imperfections and restore the protective barrier. Delaying scratch repair allows moisture and contaminants to access the substrate, initiating corrosion and potentially leading to more extensive damage. It is crucial to select repair materials that match the color and texture of the original finish to ensure a seamless repair.

- Environmental Exposure Mitigation

Minimizing exposure to harsh chemicals, extreme temperatures, and prolonged direct sunlight is essential for preserving the integrity. Avoid using abrasive cleaners or solvents that can damage the finish. Items should be shielded from prolonged exposure to direct sunlight to prevent fading or chalking. Environmental exposure should be mitigated as this exposure contributes significantly to finish degradation. Steps should be taken to minimize this where possible, for example items should be stored inside when not in use.

Adherence to these maintenance requirements is integral to maximizing the lifespan and preserving the aesthetic appeal. Proper cleaning, protective wax application, prompt scratch repair, and environmental exposure mitigation work in concert to ensure that coatings mimicking copper-tin alloys retain their intended appearance and protective properties for an extended period. Neglecting these maintenance protocols compromises finish integrity and accelerates deterioration, ultimately diminishing visual appeal and reducing lifespan. Therefore, a proactive approach to maintenance is crucial for safeguarding the investment in items employing these coatings.

Frequently Asked Questions about Bronze Finish Metal

The following section addresses common inquiries regarding coatings designed to replicate the appearance of copper-tin alloys. These questions aim to clarify typical concerns and misconceptions surrounding application, durability, and maintenance.

Question 1: Is a finish as durable as solid copper-tin alloy?

Coatings designed to mimic copper-tin alloys do not typically possess the same inherent durability as solid alloys. While they offer a degree of protection, their resistance to abrasion, corrosion, and impact is generally lower than that of the solid material.

Question 2: Can surfaces be applied to any substrate?

While these coatings can be applied to a variety of substrates, the suitability depends on factors such as surface preparation, material compatibility, and the intended application environment. Certain materials may require specific pretreatments to ensure adequate adhesion and prevent corrosion.

Question 3: What is the expected lifespan?

The lifespan is highly variable and depends on factors such as environmental exposure, maintenance practices, and the quality of the coating material. Under optimal conditions and with proper care, surfaces can maintain their aesthetic appeal for several years; however, harsh environments or neglect can significantly shorten the lifespan.

Question 4: How is it best maintained?

Optimal maintenance involves regular cleaning with mild, non-abrasive detergents, periodic application of protective waxes, and prompt repair of any scratches or abrasions. Avoiding harsh chemicals and prolonged exposure to direct sunlight is also crucial for preserving the appearance and integrity of the finish.

Question 5: Are there limitations in replicating the exact appearance?

While advanced coating technologies can closely mimic the appearance of copper-tin alloys, subtle differences in color, texture, and sheen may be noticeable under close inspection. The replication process aims to capture the overall aesthetic, but achieving a perfect match is often challenging.

Question 6: Is it suitable for exterior applications?

Surface treatments can be suitable for exterior applications, provided that the coating is specifically formulated for outdoor use and is properly maintained. Exposure to the elements can accelerate degradation, so regular cleaning and protective measures are essential.

In conclusion, while coatings designed to replicate copper-tin alloys offer a cost-effective and aesthetically pleasing alternative to solid alloys, it is essential to understand their limitations and adhere to proper maintenance practices. Careful consideration of these factors ensures that the intended appearance is preserved and the lifespan maximized.

The following sections will explore specific case studies showcasing the application of these coatings in various industries and environments.

Conclusion

The preceding discussion has comprehensively examined coatings designed to simulate copper-tin alloys, encompassing their aesthetic replication, corrosion resistance simulation, substrate variations, cost-effectiveness, and maintenance requirements. These aspects are critical in determining the suitability of these coatings for various applications, balancing the desire for visual appeal with considerations of durability and economic feasibility. The value is not just in appearance but must factor into lifespan and ultimate suitability.

Effective implementation necessitates a thorough understanding of the trade-offs involved and a commitment to proper maintenance practices. As technology advances, coatings may more closely approximate the properties of solid copper-tin alloys. Continued research and development are crucial to enhance the performance and longevity. Stakeholders are encouraged to weigh factors when specifying these finishes for their respective projects.

![Top Asheville Metal Finishing: [Your Brand] Quality Best Final Touch: Elevate Your Projects with Professional Finishing Top Asheville Metal Finishing: [Your Brand] Quality | Best Final Touch: Elevate Your Projects with Professional Finishing](https://bestfinaltouch.com/wp-content/uploads/2026/01/th-666-300x200.jpg)