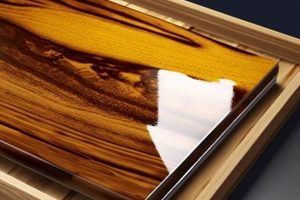

A surface treatment for wooden materials that undergoes a hardening process when exposed to ultraviolet light. This process involves applying a liquid coating that contains photoinitiators. Upon exposure to UV light, these photoinitiators trigger a rapid polymerization of the coating, resulting in a durable, hardened layer. An example includes a protective layer applied to hardwood flooring, enhancing its resistance to scratches and wear.

The utilization of this technology provides several advantages. It results in faster production times due to the rapid curing process, reduces volatile organic compound (VOC) emissions compared to traditional methods, and offers enhanced durability and resistance to chemicals and abrasion. Its historical context involves the gradual adoption across various industries seeking efficient and environmentally conscious coating solutions, replacing older, more polluting technologies.

This article will delve further into the specific types of coatings used, the equipment required for application and curing, and the diverse range of applications where this technology is employed. Furthermore, it will analyze the environmental considerations and the cost-effectiveness of this approach compared to alternative finishing methods.

Application Best Practices

Achieving optimal results necessitates adherence to specific guidelines during the application and curing processes. Proper preparation, precise application techniques, and controlled curing conditions are crucial for maximizing the benefits and ensuring a high-quality, durable finish.

Tip 1: Substrate Preparation is Paramount: Ensure the wood surface is clean, dry, and free of contaminants. Sanding to the appropriate grit level is essential for promoting adhesion and achieving a smooth, even coating.

Tip 2: Viscosity Control Enhances Application: Monitor and adjust the viscosity of the liquid coating as needed. Excessive viscosity can lead to uneven application, while insufficient viscosity may result in runs or sags.

Tip 3: Application Uniformity Matters: Apply the coating in thin, even layers using appropriate equipment, such as a spray gun or roller. Overlapping strokes are necessary to avoid missed spots and ensure complete coverage.

Tip 4: Controlled UV Exposure is Critical: Adhere to the manufacturer’s recommended UV dosage and exposure time. Insufficient exposure may result in incomplete curing, while excessive exposure can lead to yellowing or cracking.

Tip 5: Temperature and Humidity Management: Maintain consistent temperature and humidity levels in the curing environment. Extreme fluctuations can negatively impact the curing process and the final finish quality.

Tip 6: Regular Equipment Maintenance: Ensure that application and curing equipment is properly maintained and calibrated. Worn or malfunctioning equipment can lead to inconsistent results and potential defects.

Adherence to these best practices ensures a high-quality and durable protective layer, maximizing the lifespan and aesthetic appeal of the treated wood.

The subsequent section will explore common troubleshooting scenarios and address potential issues that may arise during the application and curing processes.

1. Durability

Durability, in the context of surfaces treated with ultraviolet light cured coatings, represents a critical performance characteristic defining the lifespan and resilience of the finish against wear, abrasion, and environmental factors. The enhanced resistance imparted by this process directly influences the longevity and aesthetic appeal of the finished product.

- Scratch Resistance

The cross-linked polymer network formed during the curing process imparts significant scratch resistance. Unlike traditional coatings that may soften or deform under pressure, UV-cured coatings exhibit a higher degree of hardness, preventing surface scratches and maintaining a pristine appearance. This is particularly valuable in high-traffic areas or on surfaces subjected to frequent contact.

- Chemical Resistance

Exposure to chemicals, such as cleaning agents or solvents, can degrade many conventional coatings. However, the robust chemical resistance of UV-cured coatings prevents damage from spills or routine cleaning. This attribute makes these finishes well-suited for applications in environments where chemical exposure is likely, such as laboratories or kitchens.

- Abrasion Resistance

Abrasion, resulting from repeated contact with abrasive materials, can gradually wear down the surface of a coating. The high crosslink density of UV-cured finishes provides superior abrasion resistance, extending the lifespan of the coating and reducing the need for frequent refinishing. This resistance is crucial for flooring and furniture applications, where surfaces are subject to constant wear.

- Impact Resistance

The ability of a surface to withstand impact without cracking or chipping is vital for long-term durability. UV-cured coatings, especially those formulated with flexible resins, can exhibit improved impact resistance compared to conventional coatings. This is particularly important for surfaces that may be subjected to accidental impacts or mechanical stress.

The interplay of these factorsscratch resistance, chemical resistance, abrasion resistance, and impact resistancecollectively contributes to the overall durability of a coating. The inherent properties imparted by the ultraviolet curing process result in a protective layer capable of withstanding demanding conditions, ensuring long-term performance and maintaining the aesthetic value of the underlying wood substrate.

2. Efficiency

Efficiency, in the context of ultraviolet light-cured wood finishes, represents a pivotal attribute impacting productivity, resource utilization, and overall cost-effectiveness in manufacturing and application processes. The capacity to streamline operations and minimize waste is a key driver for the adoption of this technology.

- Rapid Curing Times

Ultraviolet light-cured coatings exhibit significantly reduced curing times compared to traditional methods. Where conventional coatings may require hours or even days to fully cure, those cured with ultraviolet light achieve complete hardening in a matter of seconds or minutes. This accelerated process translates directly into increased production throughput and reduced work-in-progress inventory. A furniture manufacturer, for instance, can expedite the finishing process, allowing for faster delivery times and improved responsiveness to market demand.

- Reduced Energy Consumption

While ultraviolet light curing requires specialized lamps, the overall energy consumption is often lower than that associated with traditional thermal curing methods. The rapid curing times minimize the duration of energy input, and the localized nature of ultraviolet light exposure reduces heat loss. A case study comparing the energy footprint of a wood flooring manufacturer using both thermal and ultraviolet light curing processes demonstrated a measurable reduction in energy consumption per unit produced.

- Minimized Waste and Rework

The consistent and controlled nature of the ultraviolet light curing process reduces the incidence of defects and rework. The rapid curing prevents dust contamination and minimizes the risk of coating imperfections. A cabinet manufacturer employing ultraviolet light-cured finishes reported a significant decrease in product returns due to finish-related defects, leading to cost savings and improved customer satisfaction.

- Optimized Space Utilization

The reduced curing times associated with ultraviolet light technology allows for more efficient use of factory floor space. Manufacturers can minimize the need for extensive drying areas or storage racks, freeing up valuable space for other production activities. This optimized space utilization contributes to improved workflow and increased overall production capacity.

The collective benefits of rapid curing, reduced energy consumption, minimized waste, and optimized space utilization underscore the enhanced efficiency offered by ultraviolet light-cured coatings. These efficiencies translate into tangible cost savings, improved productivity, and enhanced competitiveness for manufacturers employing this technology. Furthermore, the environmental benefits associated with reduced energy consumption and minimized waste contribute to a more sustainable manufacturing process.

3. Consistency

Consistency represents a critical attribute in the realm of ultraviolet light-cured wood finishes, directly influencing product quality, operational efficiency, and customer satisfaction. Maintaining uniformity across various parameters during the application and curing processes is essential for achieving predictable and repeatable results.

- Formulation Stability

Maintaining a stable formulation is paramount for ensuring consistent performance of ultraviolet light-cured coatings. Variations in viscosity, pigment dispersion, or resin composition can lead to inconsistent application, uneven curing, and undesirable aesthetic outcomes. Rigorous quality control measures, including regular testing and monitoring of raw materials and finished formulations, are essential for preserving formulation stability. For instance, a slight shift in the concentration of photoinitiators can dramatically affect the curing rate and hardness of the resulting finish, leading to inconsistencies in product quality.

- Application Uniformity

Consistent application of the coating is crucial for achieving a uniform film thickness and appearance. Variations in spray patterns, roller pressure, or brush strokes can result in uneven coverage, leading to differences in gloss, color, and protection. Automated application systems, coupled with skilled operators, are often employed to minimize human error and ensure consistent application. An example is the use of robotic spray systems in furniture manufacturing to apply uniform coats, minimizing variations in finish quality across large production runs.

- Curing Parameter Control

Precise control of curing parameters, such as ultraviolet light intensity, exposure time, and temperature, is essential for ensuring consistent curing of the coating. Variations in these parameters can lead to under-curing, over-curing, or inconsistent crosslinking, resulting in compromised durability and aesthetic defects. Sophisticated curing equipment with feedback control systems is used to maintain consistent conditions throughout the curing process. For example, sensors monitor the ultraviolet light intensity and automatically adjust the lamp output to compensate for variations in voltage or lamp aging.

- Environmental Stability

The stability of the finished surface under varying environmental conditions is critical for ensuring long-term consistency in appearance and performance. Exposure to ultraviolet light, humidity, or temperature fluctuations can degrade the coating, leading to discoloration, cracking, or peeling. Formulating coatings with ultraviolet light absorbers, stabilizers, and moisture barriers can enhance environmental stability. An example is the addition of hindered amine light stabilizers (HALS) to formulations to mitigate the degradation caused by ultraviolet light exposure over extended periods.

These facets highlight the critical role of consistency in ultraviolet light-cured wood finishes. By controlling formulation stability, application uniformity, curing parameters, and environmental stability, manufacturers can ensure a high-quality, durable, and aesthetically pleasing product. The interconnected nature of these factors underscores the need for a comprehensive approach to quality control, encompassing all stages of the coating process.

4. Composition

The composition of a ultraviolet light cured wood finish is intrinsically linked to its performance characteristics, directly influencing durability, adhesion, and overall aesthetic appeal. The precise blend of resins, photoinitiators, additives, and solvents dictates the properties of the liquid coating before application and the solid film after ultraviolet light exposure. The selection of specific components and their relative concentrations represents a critical stage in the formulation process, serving as a primary determinant of the resulting finish’s ability to withstand environmental stressors and maintain its integrity over time. For example, the type of resin used (e.g., acrylic, polyester, epoxy) will influence the flexibility and hardness of the cured film, while the photoinitiator concentration controls the speed and completeness of the curing reaction.

A practical application of understanding compositional effects is evident in the formulation of finishes for high-traffic areas, such as hardwood flooring. In such scenarios, the composition is typically tailored to prioritize abrasion resistance and scratch resistance. This often involves incorporating hard resins, such as melamine-formaldehyde resins, and reinforcing additives, such as silica nanoparticles, into the formulation. Conversely, finishes intended for use on flexible wood substrates, such as veneers, may incorporate more flexible resins, such as polyurethane acrylates, to prevent cracking or delamination under stress. Furthermore, the type and concentration of solvent used impacts the viscosity of the coating and its ability to wet the wood surface, directly affecting adhesion. The omission or incorrect selection of UV absorbers can lead to premature yellowing or degradation of the finish upon exposure to sunlight, demonstrating the crucial role of these additives.

In summary, the composition of a ultraviolet light cured wood finish is not merely a mixture of ingredients but a carefully engineered system where each component plays a vital role in determining the final product’s performance. Challenges in formulation arise from the need to balance multiple, sometimes conflicting, performance requirements, such as hardness versus flexibility, or clarity versus ultraviolet light resistance. A thorough understanding of the interplay between composition and performance is essential for developing effective and durable wood finishes suitable for a wide range of applications, contributing directly to the broader goal of providing long-lasting and aesthetically pleasing wood surfaces.

5. Application

The application process is inextricably linked to the successful deployment of ultraviolet light cured wood finishes. It represents the critical juncture where the formulated coating material is transformed from a liquid state to a functional, protective layer on the wood substrate. Improper application techniques directly result in compromised performance, negating the inherent advantages of the ultraviolet light curing process. The method of application, the thickness of the coating, and the uniformity of coverage are all pivotal factors influencing the final quality and durability of the finish. For example, uneven spray application leads to variations in film thickness, resulting in inconsistencies in gloss, color, and scratch resistance. Similarly, inadequate surface preparation, such as failing to remove contaminants or properly sand the wood, will compromise adhesion, leading to premature peeling or chipping. An optimal finish necessitates a meticulously controlled application process.

Consider the application of a ultraviolet light cured coating on architectural millwork. The complexity of the shapes and contours inherent in millwork demands skilled technicians and specialized equipment. Spray application, often utilizing electrostatic techniques, is commonly employed to ensure uniform coverage across intricate profiles. Furthermore, maintaining a consistent film thickness is crucial to prevent issues such as edge build-up or sagging. Failure to adhere to these best practices not only impacts the aesthetic appearance but also compromises the protective function of the coating, leaving the wood vulnerable to moisture penetration and environmental degradation. Another application example is related to factory-applied flooring: precision rollers and automated application systems are used to apply coatings with extreme uniformity and to avoid human-introduced variation.

In conclusion, the application phase is more than simply applying a coating. It is an integral component of the ultraviolet light cured wood finish system, and its successful execution hinges on a confluence of factors. Those factors include proper surface preparation, precise application techniques, and adherence to manufacturer specifications. Recognizing the cause-and-effect relationship between application and finish performance, challenges associated with suboptimal application are addressed through training programs, equipment advancements, and rigorous quality control measures. Addressing those challenges contributes to maximizing the potential of ultraviolet light cured coatings and ensures the long-term protection and aesthetic enhancement of wood surfaces.

6. Environment

The intersection of environmental considerations and ultraviolet light-cured wood finishes is critical, reflecting a shift towards more sustainable coating technologies. Traditional wood finishing processes often involve high levels of volatile organic compound (VOC) emissions, contributing to air pollution and posing health risks. The rapid curing times associated with ultraviolet light-cured coatings significantly reduce VOC emissions. In many cases, formulations are solvent-free or utilize water-based chemistries, further minimizing environmental impact. This reduced emission profile aligns with increasingly stringent environmental regulations and consumer demand for eco-friendly products. For example, manufacturers in Europe are subject to strict VOC emission limits, driving the adoption of ultraviolet light-cured coatings as a compliance strategy.

Furthermore, the durability of ultraviolet light-cured finishes contributes to environmental sustainability by extending the lifespan of wood products. Coatings with enhanced scratch resistance and chemical resistance reduce the need for frequent refinishing or replacement, thereby conserving resources and minimizing waste. This is particularly relevant in high-use applications, such as commercial flooring or institutional furniture. An extended product lifespan translates directly into reduced resource consumption and a decreased environmental footprint. The development of bio-based resins for ultraviolet light-cured coatings represents a further advancement. These resins are derived from renewable resources, such as plant oils or agricultural byproducts, reducing reliance on petroleum-based feedstocks and further enhancing the environmental profile.

In summary, environmental concerns are a major driver in the evolution of wood finishing technologies. The use of ultraviolet light-cured coatings is one response to sustainability and is due to a combination of factors, including reduced VOC emissions, extended product lifespan, and the incorporation of bio-based materials. These are challenges in formulating coatings that meet both stringent performance requirements and environmental standards. Efforts to develop even more environmentally benign chemistries and application methods are ongoing, reflecting a commitment to minimizing the ecological impact of wood finishing processes. Recognizing and addressing the environmental implications of coating technologies is essential for fostering a more sustainable approach to wood product manufacturing.

Frequently Asked Questions about UV Cured Wood Finish

This section addresses common inquiries regarding the properties, applications, and benefits of surfaces treated with ultraviolet light-cured coatings. The information provided aims to clarify misconceptions and offer a comprehensive understanding of this finishing technology.

Question 1: What are the primary advantages of employing ultraviolet light-cured coatings over traditional wood finishes?

Ultraviolet light-cured coatings offer several advantages, including significantly faster curing times, reduced volatile organic compound (VOC) emissions, enhanced scratch and chemical resistance, and improved durability compared to many conventional wood finishes. These attributes contribute to increased production efficiency and a more environmentally sustainable finishing process.

Question 2: Is surface preparation a critical factor for ensuring optimal adhesion of ultraviolet light-cured coatings?

Yes, proper surface preparation is paramount. The wood substrate must be clean, dry, and free of contaminants. Sanding to the appropriate grit level is essential for promoting mechanical adhesion and achieving a smooth, uniform coating. Failure to adequately prepare the surface can result in adhesion failures, leading to peeling or chipping of the finish.

Question 3: Can ultraviolet light-cured coatings be applied to all types of wood species?

While ultraviolet light-cured coatings are generally compatible with most wood species, certain oily or resinous woods may require special pre-treatment to ensure proper adhesion. Testing on a small, inconspicuous area is recommended to assess compatibility and identify any potential issues before full-scale application.

Question 4: What safety precautions should be observed when working with ultraviolet light curing equipment?

Exposure to ultraviolet light radiation poses a potential hazard. Personnel working with curing equipment should wear appropriate personal protective equipment (PPE), including ultraviolet light-blocking eyewear and protective clothing. Equipment should be properly shielded to prevent accidental exposure. Regular maintenance and inspections are essential to ensure safe operation.

Question 5: Are ultraviolet light-cured coatings more expensive than conventional wood finishes?

While the initial cost of ultraviolet light curing equipment may be higher than that of traditional finishing systems, the long-term cost-effectiveness can be significant. The faster curing times, reduced waste, and improved durability contribute to lower overall production costs and reduced maintenance expenses. A thorough cost-benefit analysis should be conducted to determine the most economical finishing solution for a specific application.

Question 6: How should ultraviolet light-cured wood finishes be maintained to ensure long-term performance?

Regular cleaning with mild detergents and avoidance of harsh chemicals are recommended. The use of furniture pads or floor protectors can help prevent scratches and abrasions. Periodic inspection and touch-up of damaged areas can extend the lifespan of the finish and maintain its aesthetic appearance.

In summary, ultraviolet light-cured coatings offer a compelling combination of performance advantages and environmental benefits. However, proper application techniques, safety precautions, and maintenance practices are essential for maximizing the potential of this finishing technology.

The following section will delve into case studies showcasing successful applications of ultraviolet light-cured wood finishes in various industries.

Conclusion

This examination of ultraviolet light cured wood finish has illuminated its core attributes: durability, efficiency, consistency, and environmental impact. Its composition and application are integral factors influencing its performance. This technology represents a significant advancement in wood finishing, offering both performance enhancements and environmental advantages. However, the realization of its potential requires meticulous attention to detail throughout the entire process, from formulation to application.

Further research and development in this field should focus on optimizing the composition of coatings for enhanced sustainability and expanding the range of applications where this technology can be effectively employed. Continuous advancements will contribute to a more durable and environmentally responsible approach to wood finishing, solidifying its position as a leading solution in the industry.