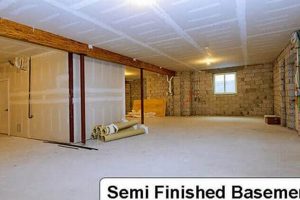

The application of a protective or decorative layer to the subterranean level of a building, post-construction, represents a crucial step in transforming a bare, functional space into a usable and aesthetically pleasing environment. This process involves selecting and applying specific materials designed to adhere to the existing substrate, enhancing both the appearance and the longevity of the finished space. For instance, applying an epoxy barrier to a concrete floor addresses potential moisture issues while simultaneously providing a durable and visually appealing surface.

This stage is vital for several reasons. It protects against moisture intrusion, inhibits mold growth, and improves the overall air quality within the structure. Furthermore, it significantly increases the value and usability of the lower level, converting it from a mere storage area to a functional living space. Historically, this phase was often overlooked, resulting in damp, unfinished basements prone to deterioration. Modern building practices recognize the substantial benefits of this procedure in terms of structural integrity, energy efficiency, and enhanced property value.

The subsequent sections will delve into the specific types of materials suitable for application, proper preparation techniques, and potential challenges encountered during the finishing process. Understanding these elements ensures a successful and long-lasting conversion of the subterranean level into a valuable and comfortable extension of the home.

Application Guidance for Subterranean Level Finishing

The following recommendations provide actionable strategies for the successful application of a protective or decorative layer during the finishing of a subterranean level. Adherence to these guidelines is crucial for achieving a durable, aesthetically pleasing, and structurally sound outcome.

Tip 1: Moisture Assessment is Paramount: Prior to commencement, conduct a thorough moisture assessment of the concrete slab and walls. High moisture levels can compromise the adhesion of applied materials and lead to future mold growth. Implement waterproofing measures, such as sealant application or drainage system improvements, as necessary.

Tip 2: Surface Preparation is Critical: Ensure the concrete surface is clean, dry, and free from contaminants. Mechanical abrasion, such as grinding or shot blasting, may be required to remove existing coatings, efflorescence, or laitance. This step enhances the bond between the substrate and the applied material.

Tip 3: Select Appropriate Materials: Choose materials specifically formulated for subterranean environments. Epoxy coatings, moisture-resistant paints, and specialized sealants offer superior protection against moisture intrusion and chemical degradation. Consider vapor permeability characteristics to allow for optimal moisture management.

Tip 4: Adhere to Manufacturer’s Specifications: Follow the manufacturer’s instructions meticulously regarding mixing ratios, application methods, and curing times. Deviations from these specifications can result in premature failure of the applied material.

Tip 5: Proper Ventilation is Essential: Ensure adequate ventilation during the application and curing process. This helps to dissipate harmful fumes and promotes proper drying of the applied material.

Tip 6: Consider a Primer Coat: Application of a primer coat before the primary application can enhance adhesion and provide a uniform surface for subsequent coats. Select a primer compatible with both the substrate and the topcoat material.

Tip 7: Apply Multiple Thin Coats: Instead of applying a single thick layer, consider applying multiple thin coats. This approach promotes better adhesion, reduces the risk of cracking, and provides a more uniform finish.

These tips highlight the importance of careful planning, proper surface preparation, and the selection of appropriate materials. Successfully applying a protective or decorative layer during the finishing of a subterranean level relies on meticulous execution and adherence to established best practices.

The subsequent sections will discuss common challenges encountered during the finishing process and strategies for overcoming them.

1. Moisture mitigation

The effective management of moisture is paramount in any subterranean finishing project. Ignoring this aspect can lead to significant structural damage, unhealthy living conditions, and premature failure of applied surface treatments. Moisture mitigation strategies directly influence the longevity and efficacy of any attempt to apply a protective or decorative layer.

- Foundation Waterproofing

Exterior waterproofing systems prevent water ingress through foundation walls. These systems, often involving membranes or coatings applied to the exterior of the foundation, minimize the amount of moisture that reaches the interior. Failing to address exterior waterproofing can overwhelm interior moisture control measures, leading to persistent dampness and coating failure.

- Sub-Slab Depressurization

Radon mitigation systems, which create negative pressure beneath the concrete slab, also inadvertently reduce moisture intrusion. By drawing air from beneath the slab, these systems limit the upward migration of water vapor. While primarily intended for radon reduction, these systems contribute to a drier environment conducive to successful coating application.

- Interior Sealants and Barriers

The application of waterproof sealants and vapor barriers directly to interior surfaces prevents moisture from penetrating the concrete. Epoxy coatings, specifically formulated for subterranean use, act as a barrier against moisture intrusion. Proper application of these sealants, with particular attention to seams and joints, is crucial for long-term protection.

- Dehumidification Systems

Mechanical dehumidification systems remove moisture from the air, creating a drier environment within the finished space. While not a primary form of moisture mitigation, dehumidifiers complement other strategies by controlling humidity levels after finishing. Reducing humidity minimizes condensation and inhibits mold growth, prolonging the lifespan of the coating.

These multifaceted approaches to moisture mitigation are essential prerequisites for a successful application of a protective or decorative layer in a subterranean environment. Ignoring any one of these facets can compromise the integrity of the finished space, leading to costly repairs and health concerns. Implementing a comprehensive moisture management strategy is, therefore, an integral part of basement finishing.

2. Surface Preparation

Surface preparation constitutes a critical and non-negotiable stage within the process of applying a protective or decorative layer to a subterranean level. Its adequacy directly dictates the adhesion, durability, and overall success of the finishing endeavor. Neglecting proper surface preparation invariably leads to premature coating failure, moisture-related problems, and an ultimately unsatisfactory outcome. The connection is causal: insufficient surface preparation causes compromised long-term performance of any applied substance.

The implications of inadequate preparation are evident in numerous scenarios. For example, applying an epoxy coating over a concrete floor contaminated with oil or grease will result in poor adhesion and subsequent delamination of the coating. Similarly, failure to remove loose or flaking paint will cause newly applied coatings to fail, as the underlying unstable layer detaches from the substrate. A real-life consequence might involve costly rework and material replacement. Proper preparation, conversely, ensures a clean, stable, and receptive surface for the application, optimizing the bond between the substrate and the applied substance. Techniques such as mechanical grinding, acid etching, and thorough cleaning are integral to this process, creating a textured surface that promotes superior adhesion. The practical significance lies in avoiding the aforementioned detrimental consequences and achieving a long-lasting, aesthetically pleasing, and functionally sound finish.

In summary, surface preparation is not merely a preliminary step but an essential component that directly influences the success of the entire endeavor. It addresses potential adhesion issues, removes contaminants, and ensures a stable base for the applied materials. Overlooking its importance results in compromised performance, increased costs, and diminished value of the finished subterranean level. Adhering to meticulous surface preparation protocols is, therefore, paramount for realizing the intended benefits and longevity of any subterranean finishing project.

3. Material selection

The selection of appropriate materials is fundamentally linked to the successful application of a protective or decorative layer to a subterranean level. Material properties directly influence the finished space’s resistance to moisture, mold growth, and structural degradation. The wrong selection can lead to costly repairs and a compromised living environment. For example, using a non-porous paint in an environment with high moisture vapor transmission can cause the paint to blister and peel, necessitating removal and reapplication. The type of concrete sealer chosen, its permeability, and its resistance to alkali are crucial considerations. Selecting materials unsuitable for subterranean conditions introduces a cascade of potential problems.

Practical applications underscore this connection. Epoxy coatings, known for their durability and moisture resistance, are frequently employed on concrete floors. However, proper application requires careful consideration of concrete porosity and surface preparation. Latex paints, while often used on walls, must be formulated with mildew inhibitors to prevent mold growth in damp environments. Substrate compatibility is also paramount; some sealants are incompatible with certain types of concrete additives, leading to adhesion failure. The cost of materials should not be the sole determining factor. Higher quality, moisture-resistant materials may have a higher initial cost but offer significant long-term savings by preventing moisture-related damage and prolonging the lifespan of the finish.

In conclusion, material selection is not a trivial consideration but a critical determinant of the long-term success of a protective or decorative layer applied to a subterranean level. Thoughtful evaluation of environmental conditions, substrate properties, and material characteristics is essential for achieving a durable, aesthetically pleasing, and healthy finished space. Overlooking these considerations introduces significant risk and the potential for costly remedial action. By prioritizing informed material selection, stakeholders can mitigate risks and ensure a lasting, high-quality result.

4. Application technique

Proper application technique is a critical determinant of the success of any attempt to apply a protective or decorative layer in a subterranean environment. The method by which materials are applied directly influences adhesion, uniformity, and long-term durability. Suboptimal application can negate the benefits of even the highest-quality materials, resulting in premature failure and compromised performance.

- Surface Preparation and Priming

Effective application begins with thorough surface preparation, followed by the application of an appropriate primer. Priming ensures proper adhesion of subsequent layers by sealing the substrate and providing a uniform surface for the topcoat. Inadequate priming can lead to uneven absorption of the topcoat, resulting in variations in color and texture. For example, applying a self-leveling epoxy to an unprimed concrete floor may result in the epoxy being absorbed unevenly, creating variations in the final surface level.

- Layer Thickness and Uniformity

The thickness and uniformity of applied layers are crucial for achieving the desired performance characteristics. Applying layers that are too thick can lead to cracking, blistering, or incomplete curing. Applying layers that are too thin may not provide adequate protection or coverage. Proper application involves applying multiple thin, uniform layers, allowing each layer to cure completely before applying the next. For example, applying a waterproofing membrane to foundation walls requires careful attention to layer thickness to ensure a continuous, impermeable barrier.

- Environmental Conditions Control

Environmental conditions, such as temperature and humidity, can significantly impact the curing and adhesion of applied materials. Extreme temperatures can affect the viscosity of the material, making it difficult to apply evenly. High humidity can interfere with the curing process, leading to incomplete cross-linking and reduced durability. Application should be performed within the manufacturer’s recommended temperature and humidity ranges. For instance, applying a concrete sealer on a hot, sunny day can cause the sealer to dry too quickly, resulting in poor adhesion and cracking.

- Tool Selection and Technique

The selection of appropriate tools and the mastery of application techniques are essential for achieving a professional finish. Different materials require different tools and techniques for optimal application. Using the wrong tools or improper techniques can result in uneven coverage, air bubbles, or surface imperfections. Proper application may involve the use of brushes, rollers, sprayers, or trowels, depending on the material and the desired finish. For example, achieving a smooth, even finish with a textured paint may require specialized rollers or spray equipment.

In conclusion, application technique is inextricably linked to the ultimate success of any endeavor to apply a protective or decorative layer in a subterranean environment. Thorough attention to surface preparation, layer thickness, environmental conditions, and tool selection is paramount for achieving a durable, aesthetically pleasing, and functionally sound finish. Neglecting these factors can compromise the performance of even the highest-quality materials, resulting in costly repairs and a compromised living environment.

5. Ventilation practices

Adequate ventilation is a crucial aspect of applying a protective or decorative layer to a subterranean level. It plays a significant role in the drying and curing of coatings, the removal of volatile organic compounds (VOCs), and the long-term maintenance of air quality within the finished space. Proper ventilation influences the durability and appearance of the finished surface as well as the health and comfort of occupants.

- VOC Removal and Air Quality

Many coatings release VOCs during application and curing. Insufficient ventilation allows these compounds to accumulate, leading to poor indoor air quality and potential health hazards. Effective ventilation removes VOCs, reducing exposure risks and improving overall air quality. For instance, during the application of epoxy flooring, proper ventilation is essential to remove fumes and prevent respiratory irritation.

- Drying and Curing Efficiency

Ventilation aids in the evaporation of solvents and the proper curing of coatings. Adequate airflow facilitates the release of moisture and promotes the chemical reactions necessary for the coating to harden and achieve its intended properties. Insufficient ventilation can prolong drying times, leading to tackiness, uneven curing, and compromised durability. The application of concrete sealers, for example, requires proper ventilation to ensure uniform drying and prevent the formation of surface defects.

- Moisture Control and Mold Prevention

Subterranean environments are often prone to moisture accumulation. Ventilation helps to remove excess moisture from the air, reducing the risk of mold growth and preventing damage to the coating. By maintaining a dry environment, ventilation contributes to the long-term integrity of the finished surface and protects the underlying structure. Proper ventilation following the application of waterproofing paint, for example, helps to prevent moisture buildup behind the coating, which could lead to blistering or peeling.

- Temperature Regulation

Ventilation can also help regulate temperature during the application and curing process. Maintaining optimal temperatures is crucial for the proper adhesion and performance of coatings. Excessive heat or cold can interfere with the curing process, resulting in defects or premature failure. During the application of specialized coatings, such as those used for thermal insulation, controlled ventilation helps to maintain consistent temperatures and ensure proper bonding.

In summary, effective ventilation practices are not merely an ancillary consideration but an integral component of the process to apply a protective or decorative layer within a subterranean level. By addressing VOC removal, drying efficiency, moisture control, and temperature regulation, proper ventilation promotes a healthier, more durable, and aesthetically pleasing finished space. Failing to implement adequate ventilation strategies can compromise the performance of coatings and create an undesirable living environment.

6. Adhesion promotion

The successful application of a protective or decorative layer to a subterranean level hinges significantly on adhesion promotion. The structural integrity and longevity of the applied material are directly dependent on its ability to firmly bond with the underlying substrate. Adhesion failure can lead to a cascade of problems, including moisture intrusion, coating delamination, and ultimately, the need for costly repairs. Proper surface preparation is paramount for effective adhesion promotion. For example, the presence of oil, dust, or loose particles on the concrete surface will prevent the coating from properly adhering. This necessitates thorough cleaning, degreasing, and potentially mechanical abrasion to create a suitable bonding surface. Without adequate adhesion, even the most expensive coating will fail to perform as intended, resulting in a waste of resources and compromised structural protection.

Chemical treatments also play a vital role in adhesion promotion. Acid etching, for instance, can create a micro-roughened surface on concrete, providing a better mechanical key for the coating. Primers, specifically formulated to enhance adhesion, act as an intermediary layer between the substrate and the topcoat. These primers penetrate the substrate, creating a strong bond and improving the overall adhesion of the coating system. The selection of compatible primers is essential; using an incompatible primer can actually hinder adhesion. Furthermore, proper mixing and application techniques are crucial for ensuring that the primer and topcoat form a cohesive and durable bond. Environmental conditions, such as temperature and humidity, must also be carefully controlled during application to optimize adhesion. Excess moisture or extreme temperatures can interfere with the curing process, resulting in a weakened bond.

In summary, adhesion promotion is an indispensable element in the process of applying a protective or decorative layer in a subterranean environment. It is not merely a preliminary step but a critical determinant of the coating’s long-term performance and durability. By prioritizing surface preparation, utilizing chemical treatments, and controlling environmental factors, a strong and lasting bond can be achieved, ensuring that the applied material effectively protects the subterranean level from moisture, mold, and other environmental hazards. Neglecting adhesion promotion can have severe consequences, leading to premature coating failure and costly remediation efforts.

7. Durability enhancement

Durability enhancement is inextricably linked to the long-term success of any effort to apply a protective or decorative layer to a subterranean level. The application of coatings, sealants, or other surface treatments aims to protect the underlying structure from moisture, physical damage, and chemical degradation. Effective durability enhancement strategies directly contribute to the longevity and structural integrity of the finished space. Failing to prioritize this aspect results in premature material degradation, necessitating frequent and costly repairs. A foundational cause-and-effect relationship exists: insufficient attention to durability leads directly to reduced lifespan and increased maintenance costs.

The importance of durability enhancement is evident in numerous practical applications. Consider the application of epoxy coatings to concrete floors. While epoxy provides a visually appealing and seamless surface, its long-term performance depends on its ability to withstand abrasion, impact, and chemical exposure. Incorporating additives that enhance scratch resistance, impact strength, and chemical resistance is crucial for maintaining the coating’s integrity over time. Similarly, the application of waterproofing membranes to foundation walls requires careful selection of materials that are resistant to UV degradation, puncture, and chemical attack from soil contaminants. The presence of these protective properties directly impacts the effective lifespan of the waterproofing system. The selection of resilient materials also reduces the need for replacements.Furthermore, the application of a protective layer will impact the structural performance of the basement for decades. This, in turn, results in considerable money saved.

In conclusion, durability enhancement is an indispensable consideration for anyone undertaking a subterranean finishing project. Its integration into the planning and execution phases is essential for achieving a long-lasting and structurally sound result. The selection of appropriate materials, the implementation of robust surface preparation techniques, and the incorporation of durability-enhancing additives are all critical components of a comprehensive strategy. By prioritizing durability, stakeholders can minimize the risk of premature failure, reduce long-term maintenance costs, and ensure the continued functionality and aesthetic appeal of the finished subterranean level, with the addition of money saved from potentially frequent repairs.

Frequently Asked Questions

The following section addresses common inquiries related to the application of protective or decorative layers in subterranean environments. The information provided aims to clarify potential misconceptions and offer practical guidance.

Question 1: What is the primary purpose of a coat to finish basement?

The primary purpose is multifaceted, encompassing moisture protection, aesthetic enhancement, and the creation of a usable living space. A properly applied protective layer mitigates moisture intrusion, inhibits mold growth, and transforms a raw concrete structure into a habitable environment.

Question 2: How crucial is surface preparation prior to application?

Surface preparation is paramount. A clean, dry, and properly prepared surface ensures optimal adhesion of the coating material. Failure to adequately prepare the surface can lead to premature coating failure and compromised moisture protection.

Question 3: What types of materials are suitable for basement finishing?

Materials specifically formulated for subterranean environments are recommended. Epoxy coatings, moisture-resistant paints, and specialized sealants offer superior protection against moisture and chemical degradation. Vapor permeability should be considered for effective moisture management.

Question 4: How does ventilation impact the success of a basement finishing project?

Ventilation is essential for removing volatile organic compounds (VOCs) released during application and curing. Proper ventilation also aids in moisture control and facilitates the drying process, contributing to a healthier and more durable finish.

Question 5: What are the potential consequences of inadequate moisture mitigation?

Inadequate moisture mitigation can lead to structural damage, mold growth, and compromised indoor air quality. Moisture intrusion can also cause coatings to blister, peel, or delaminate, necessitating costly repairs.

Question 6: How does durability enhancement contribute to the long-term performance of a finished basement?

Durability enhancement strategies, such as selecting abrasion-resistant materials and incorporating additives to improve impact strength, directly extend the lifespan of the finished space. Enhanced durability minimizes the need for frequent repairs and ensures the continued functionality of the finished basement.

These frequently asked questions highlight the importance of meticulous planning, proper execution, and the selection of appropriate materials. A successful application relies on a comprehensive understanding of these key elements.

The subsequent section will explore potential challenges encountered during the basement finishing process and provide strategies for overcoming them.

Conclusion

The preceding discussion has elucidated the multifaceted aspects of applying a protective or decorative layer to a subterranean level. From moisture mitigation to durability enhancement, each element plays a critical role in the successful transformation of a basement into a functional and aesthetically pleasing space. The information presented underscores the necessity of careful planning, meticulous execution, and the selection of appropriate materials tailored to the unique challenges presented by the subterranean environment. Neglecting any of these factors increases the risk of premature failure and compromised performance.

The application of this knowledge is paramount for homeowners and contractors alike. By adhering to established best practices and prioritizing quality over expediency, a durable, healthy, and valuable living space can be created. Further research and continuous improvement in materials and techniques will undoubtedly contribute to even more effective and long-lasting solutions for finishing subterranean levels, enhancing property value and improving the quality of life for occupants. The diligence in application will translate directly to the structural soundness and inhabitability of this integral part of the building.