A sequential, ordered approach to completing a basement conversion is crucial for effective project management. This methodology involves breaking down a large remodeling project into smaller, more manageable tasks, each with specific objectives and deliverables. For example, beginning with structural assessments and planning, continuing through framing, electrical, plumbing, and insulation, and culminating in drywall installation, flooring, and final finishes. This structured process helps ensure quality and minimize errors.

Following a defined sequence of actions offers multiple advantages, including improved budget control, reduced risk of delays, and a higher quality finished product. Historically, unstructured remodeling often led to cost overruns and project abandonment. Using a pre-planned structure mitigates these risks and allows for efficient resource allocation. Further benefits include enhanced communication between contractors and homeowners, as well as improved adherence to building codes and regulations.

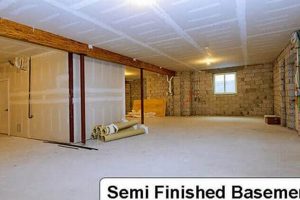

The subsequent sections of this article will detail the primary considerations in preconstruction planning, structural evaluation, and moisture management within the basement environment before proceeding to the framing stage. After the structural phases are complete, the process moves to the rough-in stages, including electrical and plumbing, and finally, insulation. The article will conclude with details on the finishing aspects, such as drywall, flooring, trim, and final aesthetic choices.

Tips for a Structured Basement Conversion

These guidelines emphasize the importance of a detailed, phased plan when undertaking a basement remodeling project to reduce errors and control costs.

Tip 1: Develop a Comprehensive Plan: A detailed project scope should be created before starting any physical work. This includes assessing the existing basement structure, identifying any potential problems, and creating a detailed floor plan.

Tip 2: Address Moisture Issues Early: Thoroughly inspect the foundation for leaks or cracks. Implement waterproofing measures before any other work begins. Consider a vapor barrier and a sump pump installation if necessary.

Tip 3: Obtain Necessary Permits: Research local building codes and obtain all required permits before starting construction. Failure to do so can result in costly delays and fines.

Tip 4: Prioritize Safety: Ensure proper ventilation and implement safety measures throughout the process. Wear appropriate protective gear, and follow all safety guidelines when using power tools.

Tip 5: Plan Electrical and Plumbing Runs: Prior to framing, carefully plan the routing of electrical wiring and plumbing pipes. This minimizes the need for alterations later and simplifies inspection.

Tip 6: Select Moisture-Resistant Materials: Choose materials that are resistant to moisture, such as treated lumber, waterproof flooring, and mold-resistant drywall.

Tip 7: Insulate Effectively: Proper insulation is vital for energy efficiency and comfort. Consider using rigid foam insulation or spray foam to minimize heat loss and reduce the risk of condensation.

Tip 8: Schedule Regular Inspections: Arrange for inspections at key stages of the project to ensure compliance with building codes. These inspections should include framing, electrical, and plumbing.

Adhering to these suggestions helps ensure a structured, efficient, and safe basement finishing project, leading to a functional and comfortable living space.

The article will now transition into a detailed examination of pre-construction strategies and considerations.

1. Planning and Permitting

The initial stage of any basement conversion involves meticulous planning and securing the necessary permits. This foundational step directly affects the subsequent progression. A well-defined plan details the intended use of the space, structural modifications, placement of electrical and plumbing systems, and compliance with local building codes. Failure to plan adequately can lead to costly revisions and delays during construction. Securing permits ensures adherence to safety standards and regulations, mitigating the risk of fines or mandated removal of non-compliant work. For example, a homeowner who neglects to obtain proper electrical permits might face significant expense if the installation is deemed unsafe and requires complete rework.

Comprehensive planning includes creating detailed blueprints, specifying materials, and obtaining quotes from qualified contractors. Permit applications require these documents, along with specifications for structural changes, electrical wiring diagrams, and plumbing layouts. In certain municipalities, energy efficiency calculations and soil testing might also be mandatory. A common error is underestimating the time required for the permit approval process; this can significantly impact project timelines. Thorough preparation, including addressing potential concerns identified by the local building department, can streamline the process.

The interrelation between planning and permitting in a basement conversion is causative; inadequate planning inevitably leads to permit application delays or denials. The process is integral to the overall success and safety of the project. Investing time and resources in thorough planning and permit acquisition safeguards against legal repercussions, ensures structural integrity, and ultimately contributes to a completed basement that meets all regulatory standards and intended uses.

2. Moisture Mitigation

The integration of moisture mitigation strategies is a prerequisite within any basement finishing project. Water intrusion and elevated humidity levels can compromise building materials, foster mold growth, and degrade indoor air quality. Within the sequential execution of basement finishing, addressing moisture issues must occur prior to any framing, insulation, or drywall installation. Neglecting this preliminary step initiates a chain reaction, ultimately leading to structural damage and potential health hazards. For example, installing insulation against a damp foundation wall traps moisture, creating an environment conducive to rot and mold propagation. This necessitates costly remediation and undermines the entire finishing endeavor.

Effective moisture mitigation encompasses several critical steps: identifying the source of moisture (e.g., hydrostatic pressure, surface runoff, condensation), implementing appropriate waterproofing measures (e.g., exterior drainage systems, interior sealants, vapor barriers), and ensuring adequate ventilation. Diagnosing the root cause requires a thorough inspection of the foundation, surrounding landscape, and existing drainage systems. Implementing a combination of interior and exterior waterproofing techniques provides a robust defense against water penetration. Moreover, installing a dehumidifier and ensuring proper airflow can manage condensation and maintain acceptable humidity levels. The selection of moisture-resistant building materials further reduces the risk of future problems.

The practical significance of understanding the interconnectedness between basement finishing and moisture mitigation lies in its preventative nature. A proactive approach, involving comprehensive assessment, targeted remediation, and continuous monitoring, is far more cost-effective than reactive measures addressing existing damage. The long-term structural integrity and the health of occupants are contingent upon effective moisture control. Implementing the right moisture mitigation techniques guarantees a finished basement is not only aesthetically pleasing but also a safe and habitable living space.

3. Framing and Layout

Framing and layout represent a pivotal phase within the sequential process of basement finishing. This stage establishes the structural framework and spatial organization of the renovated space, directly influencing functionality and aesthetic appeal. A precisely executed framework ensures structural stability and provides the foundation for subsequent installations, including electrical, plumbing, and insulation systems.

- Load-Bearing Considerations

Framing must account for load-bearing requirements, adhering to local building codes and engineering specifications. Understanding load paths and utilizing appropriate lumber dimensions prevents structural failure. Improper framing can result in sagging floors, cracked walls, or, in severe cases, structural collapse. For instance, supporting a load-bearing wall without proper footings and adequate framing members compromises the safety of the entire structure.

- Spatial Planning and Room Division

The layout dictates the division of the basement into distinct living areas. This includes determining room dimensions, door and window placements, and the configuration of hallways. A well-conceived layout optimizes space utilization and ensures seamless integration with existing architectural features. Poor spatial planning can lead to cramped living spaces, inadequate circulation, and compromised usability.

- Wall Construction and Material Selection

Framing typically involves constructing stud walls using dimensional lumber or metal studs. Material selection depends on factors such as cost, durability, and moisture resistance. Improper material selection can lead to premature decay, mold growth, and structural instability. For example, using untreated lumber in a damp basement environment accelerates rot and compromises the integrity of the framing.

- Adherence to Building Codes

Framing must comply with local building codes regarding wall height, stud spacing, fire blocking, and other safety regulations. Code violations can result in project delays, fines, and mandated rework. Failing to meet fire-resistance requirements, for example, jeopardizes the safety of occupants in the event of a fire.

The successful integration of these facets within the framing and layout stage is directly proportional to the overall success of the basement finishing endeavor. Meticulous attention to detail, adherence to building codes, and proper material selection are paramount for creating a safe, functional, and aesthetically pleasing living space. The implications of improper framing extend beyond structural concerns, impacting energy efficiency, indoor air quality, and the long-term value of the property.

4. Electrical and Plumbing

The integration of electrical and plumbing systems is a critical phase within basement finishing, demanding meticulous planning and execution. These systems provide essential utilities, directly impacting the functionality and livability of the finished space. Non-compliance with codes or improper installation can result in hazardous conditions and costly remediation.

- Electrical Wiring and Circuit Planning

Electrical wiring establishes power distribution throughout the basement, accommodating lighting, outlets, and appliances. Circuit planning dictates the number of circuits, amperage ratings, and the placement of electrical boxes. Overloading circuits can lead to overheating and fire hazards. For instance, a circuit overloaded with a space heater, television, and gaming console is a typical scenario that could cause a breaker to trip or, in severe cases, initiate an electrical fire.

- Plumbing Fixture Installation and Drainage

Plumbing fixture installation encompasses the connection of sinks, toilets, showers, and other water-using appliances to the water supply and drainage systems. Proper drainage ensures efficient waste removal and prevents water damage. Incorrectly sloped drain lines or inadequately vented plumbing can cause backups and sewer gas intrusion. A common issue is the improper connection of a basement bathroom to the main sewer line, potentially leading to flooding and unsanitary conditions.

- Adherence to Codes and Regulations

Both electrical and plumbing work must adhere to local building codes and regulations. These codes dictate material specifications, installation methods, and safety requirements. Violations can result in fines, mandated rework, and potential safety hazards. For example, failure to install ground fault circuit interrupters (GFCIs) in wet areas, such as bathrooms and kitchens, is a common code violation that increases the risk of electrical shock.

- Ventilation and Exhaust Systems

Proper ventilation is crucial for removing moisture, odors, and pollutants from the finished basement. Exhaust fans in bathrooms and kitchens expel moisture-laden air, preventing mold growth and maintaining air quality. Inadequate ventilation can lead to condensation, mold, and unhealthy living conditions. For instance, a bathroom without a functioning exhaust fan is prone to excessive humidity, fostering mold growth and damaging drywall.

These interconnected aspects of electrical and plumbing directly affect the long-term utility and safety of the finished basement. Careful planning, adherence to building codes, and proper installation techniques are paramount for creating a functional and habitable living space. The consequences of neglecting these systems range from minor inconveniences to serious safety risks, underscoring their importance within the overall basement finishing process.

5. Insulation and Ventilation

The integration of insulation and ventilation represents a critical phase within a methodical basement finishing process. These elements work synergistically to regulate temperature, manage moisture, and maintain indoor air quality, directly influencing the comfort, energy efficiency, and long-term structural integrity of the renovated space.

- Thermal Barrier Establishment

Insulation creates a thermal barrier, minimizing heat transfer between the basement and the external environment. Proper insulation reduces heating and cooling costs, enhances comfort levels, and prevents condensation on interior surfaces. The selection of insulation material, such as fiberglass batts, rigid foam boards, or spray foam, depends on factors like R-value, moisture resistance, and cost. For example, inadequate insulation in a basement can result in cold floors, drafty conditions, and increased energy consumption during winter months.

- Moisture Management and Vapor Control

Effective insulation must be paired with appropriate vapor control measures to prevent moisture accumulation within the wall assembly. Vapor barriers or retarders restrict the movement of water vapor, preventing condensation and mold growth. The placement of the vapor barrier depends on the climate and the insulation material used. In cold climates, the vapor barrier is typically installed on the warm side of the wall. Failure to manage moisture can lead to insulation degradation, structural damage, and health problems.

- Air Sealing and Infiltration Reduction

Air sealing minimizes air leakage through cracks, gaps, and penetrations in the basement envelope. Reducing air infiltration improves energy efficiency, prevents drafts, and enhances indoor air quality. Common air-sealing techniques include caulking, weatherstripping, and the application of expanding foam. Unsealed penetrations around pipes and wiring can significantly increase air leakage and compromise the performance of the insulation system.

- Ventilation Strategies for Air Quality

Ventilation systems, including exhaust fans and whole-house ventilation systems, provide fresh air and remove pollutants from the basement. Proper ventilation is essential for maintaining healthy indoor air quality and preventing moisture buildup. Exhaust fans in bathrooms and kitchens remove moisture and odors, while whole-house ventilation systems ensure continuous air exchange. Inadequate ventilation can lead to stale air, elevated levels of carbon dioxide, and the accumulation of pollutants.

The interplay between insulation and ventilation dictates the overall environmental performance of a finished basement. A comprehensive approach, incorporating appropriate insulation materials, effective vapor control, diligent air sealing, and strategic ventilation, is essential for creating a comfortable, energy-efficient, and healthy living space. The omission of any of these facets within a methodical basement finishing plan can compromise the integrity and longevity of the renovation.

6. Drywall and Finishing

Drywall and finishing represent a crucial phase within basement finishing, directly impacting the aesthetic appeal and functionality of the transformed space. The installation of drywall creates smooth, paintable surfaces, concealing the underlying framework and utilities while providing a fire-resistant barrier. The finishing process, involving taping, mudding, and sanding, ensures a seamless and uniform appearance. Without proper drywall installation and finishing techniques, imperfections such as visible seams, nail pops, and uneven surfaces detract from the overall quality of the finished basement. For example, poorly taped drywall joints are prone to cracking and becoming visually distracting, compromising the value and livability of the space.

The connection between drywall and finishing and the broader context of basement finishing is causative. The framing, electrical, plumbing, and insulation must be completed before the drywall installation can begin. Furthermore, the quality of the initial framing directly affects the ease and quality of the drywall installation. Uneven framing can lead to difficulties in achieving a smooth and level drywall surface, necessitating extensive patching and sanding. The finishing stage often involves multiple coats of joint compound, each requiring ample drying time. Failure to allow sufficient drying time can result in cracking and shrinkage, requiring additional repairs. Selecting appropriate drywall types for basement environments, such as moisture-resistant drywall, is also important to prevent issues like mold and water damage.

In conclusion, proper drywall and finishing techniques are essential for achieving a professional-looking and functional basement. This phase requires careful attention to detail, the use of appropriate materials, and adherence to industry best practices. Challenges during drywall and finishing can lead to surface imperfections and structural weakness. The impact is more significant considering drywall is not just the finish surface, it is the final element that covers all of the previously completed work and determines how it is presented to the eye, and will therefore largely determine the perception of value and quality.

7. Flooring Installation

Flooring installation represents a critical stage within the basement finishing process. It provides the foundation for comfortable and functional use of the space, while also contributing significantly to the overall aesthetic. The selection and installation of flooring must be carefully considered to address the unique challenges presented by basement environments, including moisture and temperature fluctuations. Its successful integration relies heavily on the completion of prior steps and directly influences the final usability of the remodeled area.

- Subfloor Preparation

Proper subfloor preparation is paramount for a successful flooring installation. This involves ensuring the existing concrete slab is level, clean, and dry. Any cracks or imperfections must be repaired to prevent issues with the finished floor. Moisture testing is essential to determine if a moisture barrier is required. Inadequate subfloor preparation can lead to uneven flooring, adhesive failure, and mold growth beneath the flooring material. For example, installing laminate flooring over an uneven subfloor will result in visible gaps and potential damage to the interlocking system.

- Material Selection and Suitability

Choosing the appropriate flooring material is crucial for basement environments. Options include engineered wood, luxury vinyl tile (LVT), ceramic tile, and carpet specifically designed for basements. Each material offers varying degrees of moisture resistance, durability, and comfort. Solid hardwood is generally not recommended due to its susceptibility to moisture damage. The material’s suitability directly impacts the longevity and performance of the finished floor. Selecting carpet without a moisture barrier in a damp basement will almost certainly lead to mold and mildew issues.

- Installation Techniques and Best Practices

Following proper installation techniques is essential for ensuring a long-lasting and aesthetically pleasing floor. This includes using the correct adhesive, following manufacturer’s instructions for expansion gaps, and employing appropriate cutting and trimming methods. Incorrect installation can result in loose tiles, buckling laminate, and uneven transitions. For example, failing to leave expansion gaps when installing laminate flooring can cause the floor to buckle as it expands and contracts with temperature changes.

- Moisture Management and Mitigation Strategies

Implementing moisture management strategies during flooring installation is essential to protect the flooring from water damage. This may involve applying a moisture barrier to the subfloor, selecting moisture-resistant flooring materials, and ensuring proper ventilation within the basement. Ignoring moisture concerns can lead to mold growth, warping, and adhesive failure. Installing a waterproof membrane beneath LVT flooring provides a crucial barrier against moisture migration from the concrete slab.

In summary, flooring installation within basement finishing is not simply the final aesthetic touch; it is an integrated system dependent on prior stages and critical for usability. From preparing the subfloor to selecting appropriate materials and implementing moisture mitigation strategies, each step must be meticulously executed. The choice of flooring profoundly influences comfort and durability, ensuring that the completed basement functions as a comfortable, long-lasting, and livable space. The examples cited illustrate the problems that can arise when any single stage in the installation is neglected.

Frequently Asked Questions

This section addresses common inquiries regarding the process of basement finishing, providing factual and objective answers to assist in informed decision-making.

Question 1: What is the typical order of operations in a basement finishing project?

The general sequence involves planning and permitting, moisture mitigation, framing, electrical and plumbing rough-in, insulation, drywall installation, flooring, and final trim and finishes. Deviations may occur based on specific project requirements.

Question 2: Why is moisture mitigation considered a crucial initial step?

Basements are prone to moisture accumulation, which can damage building materials and promote mold growth. Addressing moisture issues proactively minimizes long-term structural problems and health hazards.

Question 3: What type of insulation is best suited for basement walls?

Moisture-resistant insulation materials such as rigid foam board or closed-cell spray foam are generally recommended for basement walls due to their ability to resist water absorption and maintain thermal performance.

Question 4: Are permits required for basement finishing?

Most jurisdictions require permits for basement finishing projects, particularly for structural modifications, electrical work, and plumbing installations. Consult local building codes for specific requirements.

Question 5: What are the common pitfalls to avoid during basement finishing?

Common mistakes include neglecting moisture mitigation, failing to obtain necessary permits, inadequate planning, and improper installation of electrical and plumbing systems. These oversights can lead to costly rework and safety hazards.

Question 6: How can homeowners estimate the cost of a basement finishing project?

Estimating costs requires detailed planning and material selection. Obtain quotes from multiple contractors and factor in expenses for permits, materials, labor, and potential unforeseen issues. Consulting with a professional can provide a more accurate estimate.

These FAQs provide essential insights into key considerations when undertaking a basement finishing project, emphasizing planning, safety, and code compliance.

The following section presents a summary of the points outlined and provides a strategic outlook.

Basement Finishing Step by Step

This exposition has outlined the essential phases of a basement conversion, emphasizing the necessity of a structured methodology. From preliminary planning and permit acquisition to final flooring installation and finishing, each segment requires meticulous attention to detail and adherence to established building codes. Moisture mitigation has been presented as a foundational element, crucial for safeguarding the renovated space against structural damage and potential health risks. Electrical, plumbing, and insulation phases require skilled execution to ensure safety, functionality, and energy efficiency. The drywall and finishing stages contribute significantly to the aesthetic quality and livability of the finished basement.

The presented information is intended to provide a framework for successful project management. Diligent planning, accurate implementation, and adherence to safety standards are paramount. A well-executed basement finishing project enhances property value and expands habitable living space, provided the outlined methodologies are thoroughly understood and implemented. Consult experienced professionals for assistance with specific project requirements to ensure optimal results and long-term satisfaction.