A durable, solvent-based coating system, known for its exceptional resistance to wear and chemicals, is applied to hardwood floors to protect and enhance their appearance. This type of treatment typically involves multiple coats, resulting in a hard, glossy surface. For example, after sanding down bare wood, three coats of this specific coating may be applied, each requiring a curing period before the next application.

The enduring appeal of this floor protection method lies in its long-lasting qualities and ability to withstand heavy foot traffic, making it a practical choice for high-use areas. Its historical context reveals its development as a solution for environments demanding a resilient and easily maintained surface. The hard shell minimizes scratches and resists staining, preserving the integrity and beauty of the underlying wood for years to come.

The following sections will delve into the preparation process for its application, examine the specific types of solvents utilized, and compare its properties and longevity with other modern floor finishing alternatives.

Application Advice

Optimal results from this protective coating require careful attention to several key steps during the application process. Adhering to these guidelines will maximize the coating’s durability and aesthetic appeal.

Tip 1: Sanding Precision: Thoroughly sand the floor to a uniformly smooth surface prior to application. Imperfections in the sanding will be amplified by the glossy finish.

Tip 2: Cleanliness is Paramount: Vacuum and tack cloth the floor meticulously after sanding. Even minute dust particles can compromise the final appearance.

Tip 3: Solvent Compatibility: Ensure compatibility between the selected coating and any previously applied sealers or stains. Incompatibility can lead to adhesion failures and discoloration.

Tip 4: Controlled Environment: Maintain a consistent temperature and humidity level during application and curing. Fluctuations can affect drying time and finish quality.

Tip 5: Thin, Even Coats: Apply thin, even coats using a high-quality applicator. Overlapping or thick applications can result in uneven drying and potential bubbling.

Tip 6: Adequate Curing Time: Allow sufficient curing time between coats and before heavy foot traffic. Premature use can damage the uncured finish.

Tip 7: Ventilation is Crucial: Provide adequate ventilation during and after application due to the solvent-based nature of the coating. This mitigates potential health hazards and promotes proper drying.

Tip 8: Professional Assistance: For large or complex projects, consider engaging a professional flooring contractor experienced in applying this type of coating. Their expertise can ensure optimal results and minimize potential issues.

By following these guidelines, the benefits of enhanced durability, chemical resistance, and aesthetic appeal are maximized, resulting in a long-lasting and visually pleasing floor finish.

The next stage explores a comparative analysis of this coating against alternative floor protection products, emphasizing longevity and maintenance requirements.

1. Durability

Durability is a defining characteristic and a primary reason for selecting this coating for hardwood floors. The formulation creates a tough, resilient surface that resists scratching, abrasion, and impact damage far better than many other floor finishes. This enhanced resistance stems from the high solids content and cross-linking nature of the coating when it cures. In high-traffic areas, such as hallways or commercial spaces, floors finished with this coating maintain their appearance longer, reducing the need for frequent refinishing. This inherent toughness directly translates to cost savings and reduced downtime for floor maintenance.

The durability is significantly influenced by proper application techniques. A properly prepared substrate, multiple thin coats, and adequate curing time are essential for achieving optimal hardness and impact resistance. Factors such as the type of wood, the presence of any underlying sealers, and environmental conditions during application also affect the final durability. In contrast, improper sanding, inadequate ventilation, or premature use can compromise the coating’s ability to withstand wear and tear, leading to premature failure and the need for repairs. As an example, a floor properly coated in a busy retail environment will stand up to scuffs of daily foot traffic more efficiently than a floor coated with a cheaper substitute.

In summary, durability is an integral performance attribute of a high-quality protective floor coating and directly correlates with its long-term value. Maximizing this durability requires careful attention to surface preparation, application techniques, and environmental controls. While the initial investment may be higher compared to other coatings, the reduced maintenance frequency and extended lifespan resulting from its superior durability make it a cost-effective and practical choice for both residential and commercial applications seeking a robust and long-lasting floor finish solution.

2. Chemical Resistance

The ability to withstand exposure to various chemical substances without degradation is a critical attribute. This resistance is a fundamental component, directly impacting its suitability for diverse environments. Exposure to common household cleaners, spills, and industrial chemicals can cause discoloration, softening, or even complete breakdown of less resistant floor coatings. This results in aesthetic damage and compromised protective function. For example, in a kitchen setting, resistance to acidic substances like vinegar or citric juice is paramount, while in a laboratory, resistance to solvents and reagents is essential. Without adequate chemical resistance, the floor finish will require frequent repairs or replacement, increasing maintenance costs and downtime.

The inherent chemical resistance stems from the coating’s unique formulation and cross-linking properties. These properties create a dense, impenetrable barrier that prevents chemical penetration and subsequent damage. The application of multiple coats further enhances this protective effect. For instance, consider the contrasting performance of a floor coated with a solvent-based product versus a water-based acrylic when exposed to acetone. The solvent-based option will demonstrate a significantly reduced impact compared to the water-based product, highlighting the practical benefit. The chemical resistance is essential to determining it’s usefulness.

The specific chemicals encountered and their concentrations significantly influence the long-term performance of the finished surface. It’s crucial to select a finish with verified resistance to the specific chemicals anticipated in the intended environment. While it provides a robust level of protection, it is not impervious to all chemical substances. Harsh or prolonged exposure to highly corrosive chemicals may still cause damage. Therefore, understanding the limitations and appropriate maintenance practices is essential for maximizing its service life. The superior chemical resistance contributes significantly to its overall durability and makes it a preferred choice.

3. Solvent-Based

The characteristic “solvent-based” is fundamental to understanding the performance and properties of this particular coating system. It dictates application methods, potential hazards, and ultimately, the resulting finish’s durability and chemical resistance. The presence of solvents plays a crucial role in the coating’s ability to penetrate and bond with the wood substrate.

- Role of Solvents in Formulation

Solvents act as carriers for the resins, additives, and pigments within the coating. They dissolve the solid components, creating a liquid mixture that can be easily applied to the floor surface. The specific type and amount of solvent used directly influence the coating’s viscosity, drying time, and leveling properties. For example, coatings with fast-evaporating solvents will dry quickly, potentially leading to application issues if not handled with expertise. Conversely, slower-evaporating solvents allow for better leveling and minimize brush marks.

- Impact on Penetration and Adhesion

The solvent component is instrumental in facilitating deep penetration into the wood grain. This penetration enhances adhesion, ensuring a strong and durable bond between the coating and the substrate. Solvent-based coatings tend to exhibit superior adhesion compared to water-based alternatives, particularly on oily or resinous wood species. This strong adhesion contributes to the coating’s long-term resistance to peeling and chipping.

- Volatile Organic Compounds (VOCs) and Environmental Considerations

Solvent-based coatings typically contain Volatile Organic Compounds (VOCs), which evaporate during the drying process. VOCs contribute to air pollution and can pose health risks. As such, regulations governing VOC emissions have become increasingly stringent. Formulations must comply with these regulations. Proper ventilation during and after application is essential to minimize exposure and environmental impact. The VOC content is an important factor when evaluating different coating products.

- Cleaning and Maintenance Requirements

Due to the solvent-based nature of the coating, specialized cleaning products and techniques are often required. Harsh chemicals or abrasive cleaners can damage the finish, compromising its durability and appearance. Mild, pH-neutral cleaners are generally recommended for routine maintenance. Additionally, solvent-based products typically require the use of mineral spirits or other specific solvents for cleaning application tools and equipment. Careful attention to cleaning protocols is essential for preserving the integrity of the finished floor.

These facets highlight the critical role of solvents in defining the properties of this floor coating. While offering advantages in terms of durability and adhesion, the use of solvents also presents challenges related to environmental impact and safety. A comprehensive understanding of these factors is essential for making informed decisions regarding floor finishing options and ensuring proper application and maintenance practices.

4. Gloss Retention

Gloss retention is a critical performance metric, particularly pertinent to the longevity and aesthetic appeal of coated floors. It refers to the coating’s ability to maintain its original sheen and reflectivity over time, despite exposure to wear, abrasion, and environmental factors. A high degree of gloss retention signifies a superior floor finish, indicating its resistance to dulling and degradation.

- Impact of UV Exposure

Prolonged exposure to ultraviolet (UV) radiation from sunlight can significantly degrade many floor finishes, leading to fading, discoloration, and a reduction in gloss. The specific formulation of the finish can include UV inhibitors that mitigate these effects, preserving the clarity and sheen of the coating over extended periods. The presence and effectiveness of UV inhibitors directly influence the gloss retention capabilities, especially in areas with high sun exposure.

- Resistance to Micro-Scratching

Everyday foot traffic introduces micro-scratches to the floor surface, gradually dulling the finish and reducing its reflectivity. A coating with superior hardness and scratch resistance will exhibit better gloss retention because it is less susceptible to the accumulation of these microscopic imperfections. The type and concentration of hardening agents in the finish formulation contribute significantly to its scratch resistance, thus impacting the gloss retention performance.

- Chemical Stability and Cleanability

Frequent cleaning, while essential for hygiene, can also contribute to gloss reduction if the cleaning agents are too harsh or if the finish is chemically unstable. A chemically stable coating will resist degradation from commonly used cleaning products, preserving its gloss even with regular maintenance. The ease with which the floor can be cleaned without damaging the finish also plays a crucial role in maintaining its aesthetic appeal over time.

- Wear Layer Thickness and Composition

The thickness and composition of the wear layer, the outermost layer of the finish, directly impact its gloss retention. A thicker wear layer provides more material to withstand abrasion and wear, prolonging the life of the finish and maintaining its gloss for a longer duration. The specific polymers and additives used in the wear layer contribute to its hardness, scratch resistance, and UV stability, all of which influence its gloss retention characteristics. The overall result gives the ability to retain shine

Therefore, the initial investment, including the use of this coating that shows excellent gloss retention capabilities, is essential for extending the life and beauty of the flooring installation, reducing the long-term maintenance requirements and maintaining the floor’s aesthetic appeal despite normal wear and environmental stresses.

5. Application Complexity

The successful implementation hinges significantly on a complex application process. This process necessitates a skilled and knowledgeable approach to realize the coating’s full potential in terms of durability, aesthetics, and longevity. The degree of difficulty associated with application can be a substantial factor for both professional contractors and homeowners considering this finish.

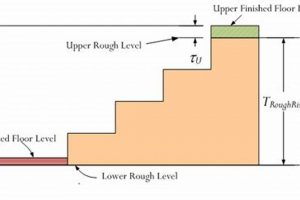

- Surface Preparation Requirements

Achieving proper adhesion demands meticulous surface preparation. This involves thorough sanding to remove existing finishes, contaminants, and imperfections. The surface must be uniformly smooth and free of dust or debris. Improper preparation can lead to adhesion failures, resulting in peeling, bubbling, or an uneven finish. The sanding process may require specialized equipment and techniques to ensure optimal results. This initial step is time consuming and demands patience.

- Multi-Coat Application Process

The application typically involves multiple thin coats, each requiring a specific drying time. Applying coats too thickly or without allowing sufficient drying time can lead to uneven curing, solvent entrapment, and a compromised finish. The number of coats and drying times can vary depending on the specific product and environmental conditions. This requirement for a multi-coat process extends the overall project timeline and demands adherence to precise application guidelines.

- Solvent-Based Composition and Ventilation

Due to the solvent-based nature, adequate ventilation is crucial during and after application. The solvents release volatile organic compounds (VOCs) that can pose health risks if inhaled. Proper ventilation requires the use of respirators and opening windows or using ventilation systems to ensure adequate airflow. Ignoring these precautions can result in exposure to harmful fumes and compromise the health of the applicator and occupants.

- Expertise and Skill Requirements

Achieving a professional-looking finish requires a certain level of expertise and skill. This includes knowledge of proper application techniques, equipment operation, and troubleshooting potential issues. Factors such as temperature, humidity, and air movement can affect the drying process and final appearance. Experienced applicators can adapt to these variables and make adjustments to ensure optimal results. Novice applicators may struggle to achieve a consistent and flawless finish, potentially leading to dissatisfaction with the final outcome.

The complexity of the application process represents a significant consideration. While the durability and aesthetic benefits are undeniable, the expertise, preparation, and precautions required make it a demanding endeavor. The level of commitment and skill required to achieve a satisfactory outcome should be carefully evaluated before undertaking such a project.

6. Curing Time

Curing time is a critical determinant of the performance and longevity. It profoundly influences the ultimate hardness, chemical resistance, and overall durability, shaping the floor’s resilience and lifespan.

- Solvent Evaporation and Cross-linking

During the curing phase, solvents evaporate from the coating, facilitating the cross-linking of resin molecules. This process forms a dense, interconnected network that imparts the characteristic hardness and chemical resistance. Insufficient curing time hinders complete solvent evaporation and cross-linking, resulting in a softer, more vulnerable finish. For instance, premature use of a floor before the coating has fully cured can lead to indentations, scratches, and solvent entrapment, compromising the integrity and appearance of the flooring.

- Environmental Factors

Temperature and humidity significantly affect the curing rate. Higher temperatures generally accelerate solvent evaporation and cross-linking, while high humidity can impede the process. It is crucial to maintain a controlled environment within the recommended temperature and humidity ranges to ensure proper curing. As an illustration, applying the coating in a damp, cool environment can prolong the curing time and potentially result in a cloudy or tacky finish.

- Impact on Durability and Resistance

Adequate curing time is essential for achieving the desired level of durability and resistance. Premature exposure to heavy foot traffic, furniture, or chemicals can damage the uncured finish, compromising its protective properties. The curing stage is the floor coatings opportunity to form a secure bond. Fully cured flooring will stand up to the daily grind.

- Recoating Intervals

If multiple coats are applied, appropriate intervals must be observed between applications to allow each coat to partially cure. Applying subsequent coats too soon can trap solvents, leading to an uneven finish or adhesion problems. Each layer needs adequate drying time before proceeding with the next layer.

The influence of curing time is a key determinant of success. Adhering to the manufacturer’s recommended curing times is essential to achieving the coating’s full potential and ensuring long-lasting performance. A commitment to precision pays dividends in flooring’s ultimate resilience.

7. Long-Lasting

The attribute “long-lasting” is intrinsically linked to the value proposition. It’s often cited as a primary reason for its selection. This longevity stems from a combination of factors inherent in its formulation and application process, resulting in a floor finish designed to withstand years of wear and tear.

- High Abrasion Resistance

The coating exhibits exceptional resistance to abrasion, a common cause of floor finish degradation. The dense, cross-linked polymer structure minimizes scratching and surface wear from foot traffic, furniture movement, and cleaning activities. For instance, in a busy retail environment, a floor finished with this coating will maintain its appearance significantly longer than floors finished with less durable alternatives, requiring less frequent refinishing.

- Superior Chemical Resistance

Resistance to chemical damage directly contributes to the long-lasting nature of the coating. Its formulation protects against spills and cleaning agents that can degrade other floor finishes. Spills of common household substances, such as vinegar, coffee, or cleaning solutions, will not readily stain or damage the surface, preserving its appearance and integrity. This resistance minimizes the need for specialized cleaning products or frequent refinishing due to chemical damage.

- Resistance to UV Degradation

Prolonged exposure to ultraviolet (UV) radiation from sunlight can cause fading, yellowing, and overall degradation of many floor finishes. Formulations often include UV inhibitors to mitigate these effects. In sun-drenched rooms, floors finished with UV-resistant coatings will maintain their color and gloss for a longer period, reducing the need for costly and disruptive refinishing.

- Proper Application and Maintenance

The longevity depends on both the quality of the product and proper application and maintenance practices. Following recommended application guidelines, including thorough surface preparation and appropriate drying times, is crucial for maximizing the coating’s durability. Regular cleaning with appropriate cleaning products and avoiding harsh chemicals or abrasive cleaners will further extend the lifespan of the floor finish.

The “long-lasting” characteristic of is not merely a marketing claim; it is a direct result of its inherent properties and the attention given to its application and maintenance. By selecting a coating system, coupled with proper care, property owners can expect a floor finish that maintains its beauty and protective qualities for years to come, providing a significant return on their investment.

Frequently Asked Questions about Swedish Floor Finish

This section addresses common inquiries and misconceptions regarding this specific type of floor coating. The following questions and answers aim to provide clarity and assist in informed decision-making.

Question 1: Is this coating suitable for all types of wood flooring?

While generally applicable to most hardwood species, certain exotic or oily woods may require specialized preparation or alternative finishing systems. Consultation with a flooring professional is advisable for non-standard wood types to ensure compatibility and optimal adhesion.

Question 2: How does its durability compare to polyurethane finishes?

It is often considered more durable and chemical-resistant than conventional polyurethane finishes. Its solvent-based formulation and cross-linking properties contribute to a harder, more resilient surface. However, specific performance characteristics can vary depending on the product formulation and application techniques.

Question 3: What are the primary health and safety concerns associated with its application?

Due to its solvent-based nature, the primary health and safety concerns involve exposure to volatile organic compounds (VOCs). Proper ventilation, the use of respirators, and adherence to safety guidelines are essential during application and curing to minimize potential health risks.

Question 4: Can it be applied over existing floor finishes?

Generally, it is not recommended to apply it over existing finishes without proper preparation, which typically involves complete removal of the old finish through sanding. Applying over incompatible finishes can lead to adhesion failures, discoloration, or other undesirable outcomes.

Question 5: What is the typical lifespan of a floor finished with this coating?

The lifespan can vary depending on factors such as foot traffic, maintenance practices, and environmental conditions. However, when properly applied and maintained, it can last for 10-20 years or more before requiring refinishing.

Question 6: What are the recommended cleaning and maintenance procedures?

Gentle cleaning with pH-neutral cleaning products and avoiding harsh chemicals or abrasive cleaners is recommended. Regular sweeping or vacuuming to remove dirt and debris can help prevent scratching and maintain the appearance of the floor. Promptly wiping up spills is also crucial to prevent staining or damage.

In summary, it offers significant benefits in terms of durability and longevity when properly applied and maintained. However, awareness of health and safety considerations and adherence to recommended application procedures are essential for a successful outcome.

The next section provides a comparative analysis against modern alternatives, highlighting trade-offs related to cost, environmental impact, and application complexity.

Conclusion

The preceding analysis has illuminated various facets of the floor coating, encompassing its application complexities, durability characteristics, and safety considerations. The evaluation has underscored the importance of informed decision-making, emphasizing the necessity of balancing performance attributes with practical constraints.

The enduring relevance of the coating stems from its established track record of delivering resilient and aesthetically pleasing floor surfaces. However, prospective users must critically assess its suitability within the context of evolving environmental standards and the emergence of alternative finishing technologies. Further research and diligent adherence to best practices remain paramount for realizing the full potential of this established floor finishing method.